ANSI Z87.1 certification focuses on impact protection and specific performance standards for safety eyewear in the United States, ensuring resistance to high-velocity impacts and chemical splash hazards. EN166 is a European standard emphasizing optical clarity, mechanical strength, and coverage, with various classifications for different hazards including low energy impact and molten metals. Pet owners prioritizing safety equipment should consider these standards to select protective gear that meets regional regulations and provides effective protection against potential pet-related injuries.

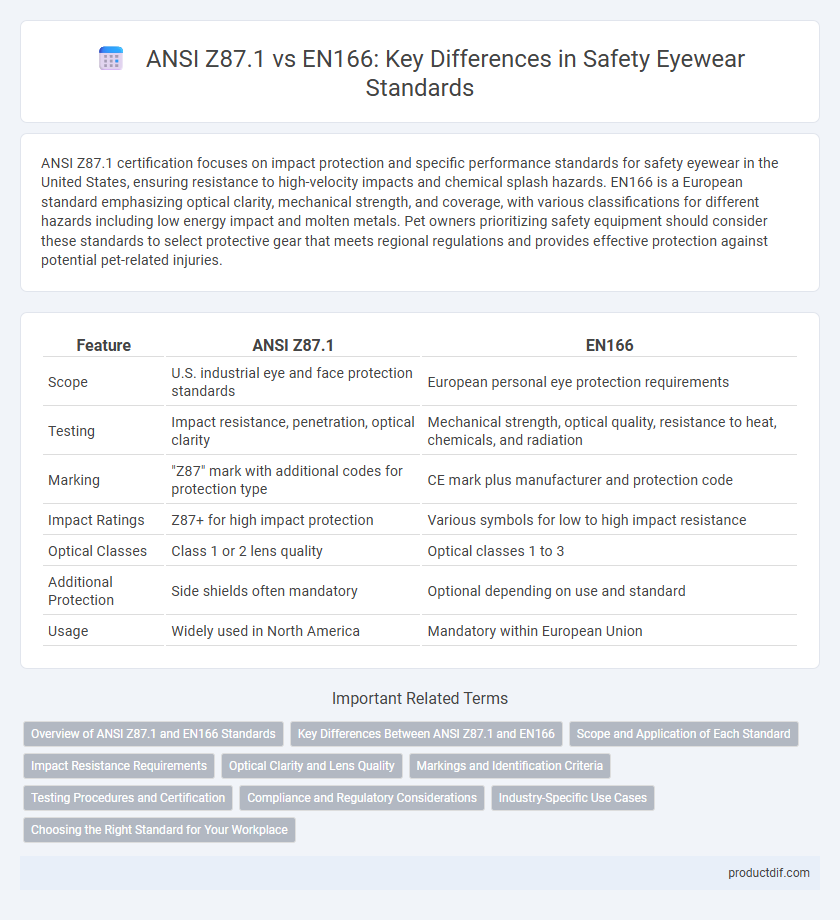

Table of Comparison

| Feature | ANSI Z87.1 | EN166 |

|---|---|---|

| Scope | U.S. industrial eye and face protection standards | European personal eye protection requirements |

| Testing | Impact resistance, penetration, optical clarity | Mechanical strength, optical quality, resistance to heat, chemicals, and radiation |

| Marking | "Z87" mark with additional codes for protection type | CE mark plus manufacturer and protection code |

| Impact Ratings | Z87+ for high impact protection | Various symbols for low to high impact resistance |

| Optical Classes | Class 1 or 2 lens quality | Optical classes 1 to 3 |

| Additional Protection | Side shields often mandatory | Optional depending on use and standard |

| Usage | Widely used in North America | Mandatory within European Union |

Overview of ANSI Z87.1 and EN166 Standards

ANSI Z87.1 and EN166 are key safety standards governing protective eyewear in the United States and Europe, respectively. ANSI Z87.1 specifies requirements for impact resistance, optical clarity, and coverage to ensure eye protection in industrial environments, while EN166 encompasses broader criteria including mechanical strength, field of vision, and resistance to various hazards. Both standards focus on rigorous testing to certify safety glasses and goggles, supporting workplace compliance and user safety.

Key Differences Between ANSI Z87.1 and EN166

ANSI Z87.1 and EN166 are two primary standards for safety eyewear in the United States and Europe, respectively, each specifying distinct performance requirements and testing methods. ANSI Z87.1 emphasizes impact resistance and is mandatory for occupational and educational applications in the U.S., while EN166 includes additional criteria like optical clarity, field of vision, and protection against various hazards, making it more comprehensive for diverse European industrial environments. Differences also arise in marking and certification processes, where ANSI Z87.1 uses a numerical rating system and EN166 employs alphanumeric codes to denote protection levels and lens types.

Scope and Application of Each Standard

ANSI Z87.1 specifies safety requirements for eye and face protection used in occupational and educational settings across the United States, covering impact resistance, optical clarity, and coverage to safeguard against hazards such as flying debris, chemical splashes, and radiation. EN166 is a European standard that outlines specifications for personal eye protection, emphasizing mechanical strength, field of vision, and protection against various risks including dust, molten metal, and harmful optical radiation in industrial environments. While ANSI Z87.1 focuses on workplace safety within North America, EN166 provides a broader scope applicable to diverse European industries with strict guidelines on marking and performance criteria for protective eyewear.

Impact Resistance Requirements

ANSI Z87.1 mandates rigorous impact resistance testing with high-velocity and high-mass impact tests to ensure eyewear withstands industrial hazards, requiring lenses to resist penetration and shattering. EN166 specifies impact protection levels through varying classifications such as "S" for increased robustness and "F," "B," or "A" ratings for low, medium, and high impact energy, respectively, demonstrated via standardized impact tests with steel balls at defined velocities. Both standards emphasize protecting eyes from impact risks, but ANSI Z87.1 often involves more stringent criteria for high-impact industrial environments compared to the broader EN166 classifications used across Europe.

Optical Clarity and Lens Quality

ANSI Z87.1 and EN166 standards both regulate safety eyewear, but they differ significantly in optical clarity and lens quality requirements. ANSI Z87.1 emphasizes impact resistance and lens strength, allowing for a cloudier optical quality compared to EN166, which enforces stringent optical clarity through higher-grade materials and lens coatings to minimize distortion. EN166 lenses often provide superior vision accuracy and comfort in critical work environments due to their rigorous optical performance standards.

Markings and Identification Criteria

ANSI Z87.1 safety eyewear requires markings on the frame and lenses to indicate manufacturer, impact rating, and lens type, ensuring clear identification of protective qualities. EN166 markings include the manufacturer's logo, optical class, and specific use codes directly on the lens, providing detailed compliance with European safety standards. Both standards emphasize traceability and protective performance, but EN166 offers more granular markings related to environmental resistance and impact protection levels.

Testing Procedures and Certification

ANSI Z87.1 and EN166 set rigorous standards for safety equipment, with ANSI Z87.1 emphasizing impact resistance through high-velocity and high-mass testing, while EN166 incorporates comprehensive tests including optical clarity, robustness against various hazards, and resistance to flames and chemicals. Certification under ANSI Z87.1 is governed by the American National Standards Institute, requiring manufacturers to validate compliance via accredited labs focusing on mechanical, optical, and environmental durability tests. EN166 certification, overseen by the European Committee for Standardization, involves detailed laboratory evaluations ensuring protection against mechanical impacts, optical radiation, and specific environmental factors tailored to diverse industrial applications.

Compliance and Regulatory Considerations

ANSI Z87.1 and EN166 are critical standards governing safety eyewear compliance in the United States and Europe, respectively, ensuring protection against impact, radiation, and chemical hazards. Compliance with ANSI Z87.1 mandates rigorous testing for high-velocity impact resistance and optical clarity, meeting OSHA requirements for workplace safety in the U.S. In contrast, EN166 focuses on a broader range of personal protective equipment certifications across diverse European markets, emphasizing versatility and conformity with EU regulations.

Industry-Specific Use Cases

ANSI Z87.1 standard primarily addresses eye and face protection requirements for American industrial sectors such as manufacturing, construction, and healthcare, ensuring compliance with impact resistance and optical clarity suited for these environments. EN166, used predominantly in Europe, provides comprehensive guidelines for protective eyewear across diverse industries including chemical processing, metalworking, and woodworking, emphasizing resistance to various hazards like dust, molten metal, and radiation. The choice between ANSI Z87.1 and EN166 depends on regional regulatory adherence and specific industry hazards, with ANSI Z87.1 tailored towards high-impact protection and EN166 offering broader environmental hazard coverage.

Choosing the Right Standard for Your Workplace

Selecting the appropriate safety eyewear standard depends on the regulatory requirements and environmental hazards present in your workplace. ANSI Z87.1 certification emphasizes impact resistance and clarity for use primarily in North American industries, while EN166 focuses on a broader range of protection criteria including resistance to optical radiation and chemical splashes, commonly required in European settings. Evaluating hazard types and compliance obligations ensures that employers provide effective eye protection, enhancing worker safety and meeting legal standards.

ANSI Z87.1 vs EN166 Infographic

productdif.com

productdif.com