Self-contained breathing apparatus (SCBA) provides an independent air supply from a tank, making it essential for environments with unknown or hazardous atmospheres, ensuring complete respiratory protection. Air-purifying respirators (APRs) filter contaminants from ambient air but are only effective when oxygen levels are sufficient and hazards are identifiable. Choosing between SCBA and APR depends on the specific safety requirements and air quality conditions of the pet safety environment.

Table of Comparison

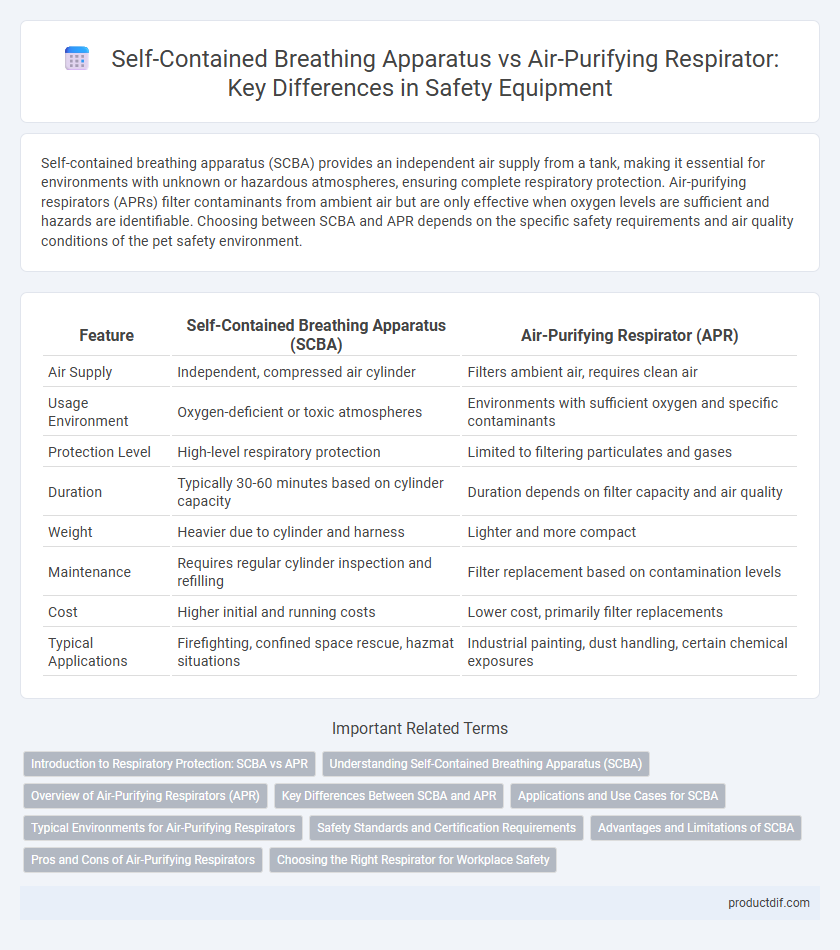

| Feature | Self-Contained Breathing Apparatus (SCBA) | Air-Purifying Respirator (APR) |

|---|---|---|

| Air Supply | Independent, compressed air cylinder | Filters ambient air, requires clean air |

| Usage Environment | Oxygen-deficient or toxic atmospheres | Environments with sufficient oxygen and specific contaminants |

| Protection Level | High-level respiratory protection | Limited to filtering particulates and gases |

| Duration | Typically 30-60 minutes based on cylinder capacity | Duration depends on filter capacity and air quality |

| Weight | Heavier due to cylinder and harness | Lighter and more compact |

| Maintenance | Requires regular cylinder inspection and refilling | Filter replacement based on contamination levels |

| Cost | Higher initial and running costs | Lower cost, primarily filter replacements |

| Typical Applications | Firefighting, confined space rescue, hazmat situations | Industrial painting, dust handling, certain chemical exposures |

Introduction to Respiratory Protection: SCBA vs APR

Self-contained breathing apparatus (SCBA) provides independent air supply vital for environments with oxygen deficiency or toxic contaminants, offering maximum respiratory protection in hazardous settings. Air-purifying respirators (APR) filter ambient air to remove harmful particles or gases but rely on sufficient oxygen levels and proper filter selection for effectiveness. Choosing between SCBA and APR depends on specific hazard types, oxygen availability, and duration of exposure in workplace safety protocols.

Understanding Self-Contained Breathing Apparatus (SCBA)

Self-Contained Breathing Apparatus (SCBA) provides a reliable, independent air supply, essential for environments with toxic gases, oxygen deficiency, or smoke, commonly used by firefighters and rescue teams. Unlike Air-Purifying Respirators (APRs) that filter ambient air, SCBAs deliver breathable air from a high-pressure cylinder, ensuring protection in immediately dangerous to life or health (IDLH) conditions. Key components include a facepiece, regulator, air cylinder, and harness, designed to maintain a secure seal and uninterrupted airflow for extended use in hazardous atmospheres.

Overview of Air-Purifying Respirators (APR)

Air-purifying respirators (APRs) filter contaminants from ambient air using replaceable cartridges or filters, making them suitable for environments with sufficient oxygen levels. Unlike self-contained breathing apparatuses (SCBA), APRs do not supply oxygen but rely on the user's surrounding air quality. Common APR types include half-mask, full-face, and powered air-purifying respirators (PAPRs), each offering varying levels of protection against particulates, gases, and vapors.

Key Differences Between SCBA and APR

Self-contained breathing apparatus (SCBA) provides independent air supply through a compressed air tank, enabling use in oxygen-deficient or highly toxic environments. Air-purifying respirators (APR) filter contaminants from ambient air but rely on sufficient oxygen levels and are unsuitable for confined spaces with hazardous atmospheres. Key differences involve SCBA's ability to protect in immediately dangerous to life or health (IDLH) conditions versus APR's limitation to non-IDLH environments with adequate oxygen.

Applications and Use Cases for SCBA

Self-contained breathing apparatus (SCBA) is primarily used in hazardous environments such as firefighting, confined space entry, and chemical spill response where oxygen levels are insufficient or unknown. It provides a reliable supply of breathable air independent of ambient conditions, ensuring worker safety in toxic atmospheres or oxygen-deficient zones. SCBA is essential for emergency responders and industrial workers operating in environments with high concentrations of harmful gases, smoke, or particulate matter.

Typical Environments for Air-Purifying Respirators

Air-purifying respirators (APRs) are typically used in environments where contaminants are known, such as industrial settings with dust, fumes, and chemical vapors, including manufacturing plants, painting operations, and laboratories. These respirators are suitable for areas with adequate oxygen levels and moderate hazard concentrations, making them ideal for routine maintenance, chemical handling, and construction sites where airborne pollutants are present but oxygen deficiency is not a concern. Unlike self-contained breathing apparatus (SCBA), APRs cannot be used in confined spaces with low oxygen or unknown toxic atmospheres, limiting their application to controlled or predictable environments.

Safety Standards and Certification Requirements

Self-contained breathing apparatus (SCBA) must comply with rigorous standards such as NFPA 1981 and NIOSH certification, ensuring complete isolation from hazardous environments and reliable air supply. Air-purifying respirators (APR) require adherence to NIOSH 42 CFR Part 84 standards, which focus on filtration efficiency and suitability for specific contaminants rather than independent air sources. Both types of equipment demand stringent testing for seal integrity, airflow, and durability to meet occupational safety regulations and provide certified respiratory protection.

Advantages and Limitations of SCBA

Self-contained breathing apparatus (SCBA) provides independent, high-quality breathable air, making it ideal for hazardous environments with oxygen deficiency or toxic contaminants, ensuring maximum user safety. Its main advantage is the ability to supply clean air without reliance on external sources, but limitations include bulkiness, limited air supply duration, and increased weight, which can reduce mobility and endurance. SCBA units require thorough training for effective use and regular maintenance to guarantee reliability in emergency scenarios.

Pros and Cons of Air-Purifying Respirators

Air-purifying respirators (APRs) offer lightweight and cost-effective protection by filtering contaminants from ambient air, making them ideal for environments with sufficient oxygen levels. However, APRs are limited by their dependency on specific filter types for various contaminants and are ineffective in oxygen-deficient or immediately dangerous to life or health (IDLH) conditions. Their ease of use and lower maintenance compared to self-contained breathing apparatus (SCBA) make APRs suitable for non-IDLH environments but pose significant risks if used improperly in hazardous atmospheres.

Choosing the Right Respirator for Workplace Safety

Self-contained breathing apparatus (SCBA) offers independent air supply, ideal for environments with oxygen deficiency or high contaminant levels, while air-purifying respirators (APR) filter ambient air and are suitable for areas with adequate oxygen and specific airborne hazards. Selecting the right respirator involves assessing workplace conditions, contaminant types, concentration levels, and duration of exposure to ensure optimal respiratory protection. Regulatory standards such as OSHA and NIOSH guidelines provide essential criteria for respirator selection, ensuring compliance and worker safety.

Self-contained breathing apparatus vs Air-purifying respirator Infographic

productdif.com

productdif.com