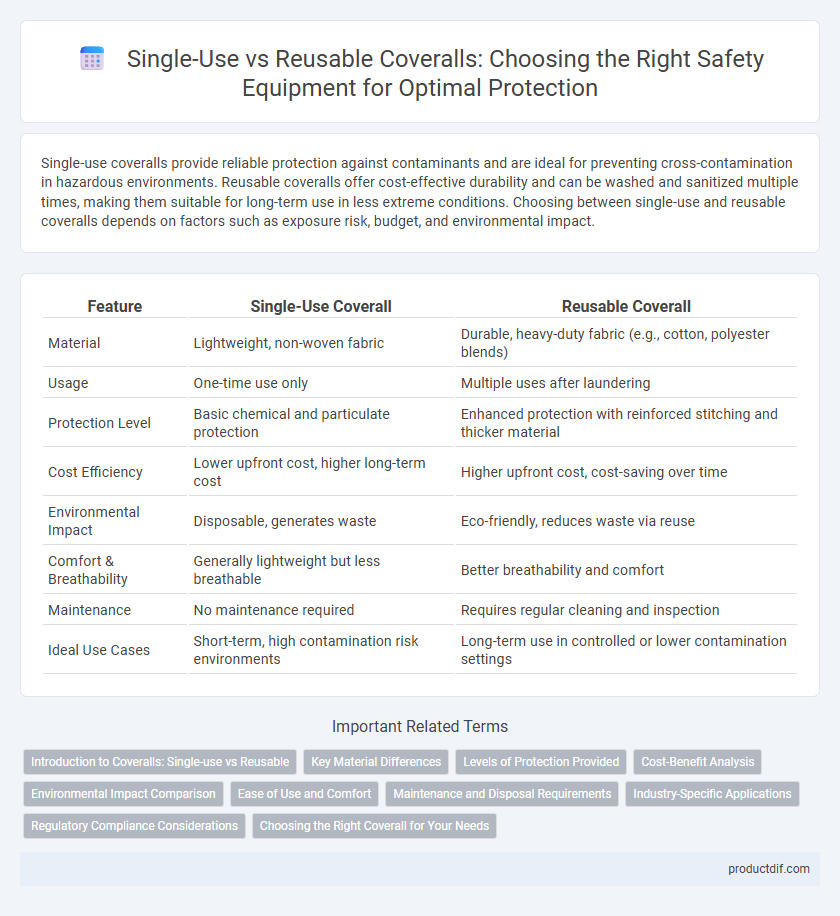

Single-use coveralls provide reliable protection against contaminants and are ideal for preventing cross-contamination in hazardous environments. Reusable coveralls offer cost-effective durability and can be washed and sanitized multiple times, making them suitable for long-term use in less extreme conditions. Choosing between single-use and reusable coveralls depends on factors such as exposure risk, budget, and environmental impact.

Table of Comparison

| Feature | Single-Use Coverall | Reusable Coverall |

|---|---|---|

| Material | Lightweight, non-woven fabric | Durable, heavy-duty fabric (e.g., cotton, polyester blends) |

| Usage | One-time use only | Multiple uses after laundering |

| Protection Level | Basic chemical and particulate protection | Enhanced protection with reinforced stitching and thicker material |

| Cost Efficiency | Lower upfront cost, higher long-term cost | Higher upfront cost, cost-saving over time |

| Environmental Impact | Disposable, generates waste | Eco-friendly, reduces waste via reuse |

| Comfort & Breathability | Generally lightweight but less breathable | Better breathability and comfort |

| Maintenance | No maintenance required | Requires regular cleaning and inspection |

| Ideal Use Cases | Short-term, high contamination risk environments | Long-term use in controlled or lower contamination settings |

Introduction to Coveralls: Single-use vs Reusable

Single-use coveralls provide effective protection against contaminants while minimizing cross-contamination risks, making them ideal for environments requiring strict hygiene. Reusable coveralls, constructed from durable materials, offer long-term cost efficiency and environmental benefits through repeated laundering and use. Both types vary in protection levels, comfort, and applications based on industrial needs and safety standards.

Key Material Differences

Single-use coveralls are often made from lightweight polypropylene or polyethylene, providing effective barrier protection against contaminants but limited durability. Reusable coveralls utilize heavier-duty materials like woven polyester or treated cotton blends, engineered for multiple wash cycles and enhanced abrasion resistance. The choice of material directly impacts protection level, comfort, and lifecycle cost within industrial safety equipment applications.

Levels of Protection Provided

Single-use coveralls offer reliable protection against low-level particulate hazards and light liquid splashes, making them suitable for short-term, disposable safety needs. Reusable coveralls provide higher durability and enhanced barrier properties, often meeting multiple protection standards for chemical, biological, and particulate exposure in demanding industrial environments. Selecting the appropriate coverall depends on the specific hazard level, frequency of use, and contamination risk.

Cost-Benefit Analysis

Single-use coveralls provide cost efficiency by reducing laundering expenses and minimizing cross-contamination risks in hazardous environments, making them ideal for short-term or infrequent use. Reusable coveralls, though requiring higher upfront investment and ongoing maintenance costs, yield long-term savings and environmental benefits through durability and multiple uses. A thorough cost-benefit analysis should consider frequency of use, contamination levels, laundering capabilities, and disposal costs to determine the most economical and safe option for specific workplace conditions.

Environmental Impact Comparison

Single-use coveralls generate significant waste due to their disposable nature, contributing to landfill accumulation and environmental pollution. Reusable coveralls offer a sustainable alternative by reducing waste volume and resource consumption through multiple use cycles, lowering their overall carbon footprint. Lifecycle assessments reveal that reusable coveralls have a substantially lower environmental impact in terms of energy use, water consumption, and greenhouse gas emissions compared to single-use options.

Ease of Use and Comfort

Single-use coveralls offer lightweight designs that enhance mobility and reduce heat retention, making them easier to wear for short durations in high-contamination environments. Reusable coveralls provide adjustable fits and breathable fabrics that improve comfort during extended use while maintaining durability through multiple wash cycles. Workers often prefer disposable coveralls for convenience and contamination control, whereas reusable options are favored for long-term comfort and cost-effectiveness.

Maintenance and Disposal Requirements

Single-use coveralls require no maintenance and must be disposed of after one use to prevent contamination, making them ideal for hazardous environments where cross-contamination risk is high. Reusable coveralls demand rigorous cleaning, decontamination, and inspection protocols to maintain protective integrity over multiple uses, contributing to higher long-term cost efficiency and environmental sustainability. Proper disposal of single-use coveralls involves adherence to hazardous waste regulations, whereas reusable coveralls require systematic laundering processes compliant with safety standards.

Industry-Specific Applications

Single-use coveralls are ideal for industries requiring strict contamination control, such as pharmaceuticals and healthcare, where preventing cross-contamination is critical. Reusable coveralls offer durability and cost-efficiency in manufacturing, construction, and maintenance environments with moderate exposure to hazards. Selecting coveralls based on industry-specific needs optimizes worker protection and operational sustainability.

Regulatory Compliance Considerations

Single-use coveralls often meet strict regulatory standards for contamination control in hazardous environments, ensuring compliance in industries such as healthcare and chemical manufacturing. Reusable coveralls require rigorous cleaning and maintenance protocols to maintain certification under standards like OSHA and ISO, which can increase operational complexity. Choosing between single-use and reusable coveralls depends on balancing compliance with regulatory guidelines, cost-effectiveness, and the specific safety requirements of the workplace.

Choosing the Right Coverall for Your Needs

Single-use coveralls offer lightweight protection against contaminants and are ideal for environments requiring strict hygiene to prevent cross-contamination, such as medical or cleanroom settings. Reusable coveralls provide durable, cost-effective protection suitable for industries with frequent exposure to chemicals, oils, or abrasives, including manufacturing and construction. Selecting the right coverall depends on factors like contamination risk, durability requirements, budget constraints, and environmental impact considerations.

Single-use coverall vs Reusable coverall Infographic

productdif.com

productdif.com