Fall arrest harnesses are designed to catch a person during a fall, minimizing injury by distributing force and preventing impact with the ground. Fall restraint systems, on the other hand, prevent workers from reaching fall hazards by restricting movement near edges or openings. Both systems are critical in workplace safety, with fall arrest harnesses used when fall risk cannot be entirely eliminated and fall restraint systems employed to avoid falls altogether.

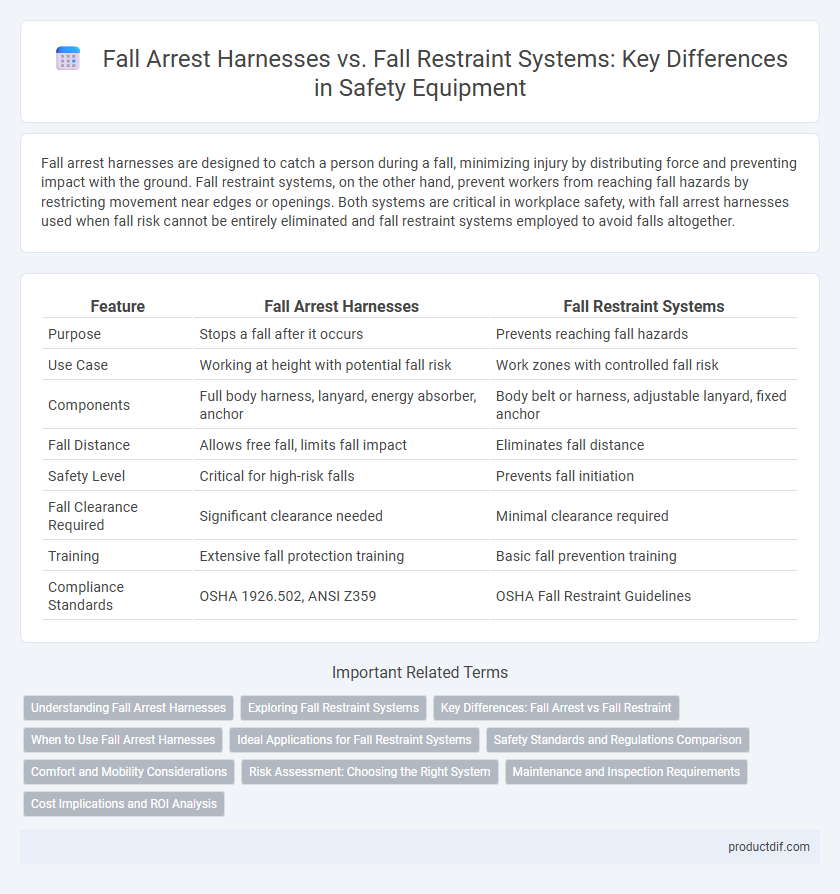

Table of Comparison

| Feature | Fall Arrest Harnesses | Fall Restraint Systems |

|---|---|---|

| Purpose | Stops a fall after it occurs | Prevents reaching fall hazards |

| Use Case | Working at height with potential fall risk | Work zones with controlled fall risk |

| Components | Full body harness, lanyard, energy absorber, anchor | Body belt or harness, adjustable lanyard, fixed anchor |

| Fall Distance | Allows free fall, limits fall impact | Eliminates fall distance |

| Safety Level | Critical for high-risk falls | Prevents fall initiation |

| Fall Clearance Required | Significant clearance needed | Minimal clearance required |

| Training | Extensive fall protection training | Basic fall prevention training |

| Compliance Standards | OSHA 1926.502, ANSI Z359 | OSHA Fall Restraint Guidelines |

Understanding Fall Arrest Harnesses

Fall arrest harnesses are critical safety equipment designed to protect workers from serious injury by catching them during a fall. These harnesses distribute the force of impact across the body, reducing the risk of trauma, and are typically equipped with shock-absorbing lanyards and secure attachment points. Understanding the correct use and fit of fall arrest harnesses is essential to ensure maximum protection in hazardous working environments at heights.

Exploring Fall Restraint Systems

Fall restraint systems prevent workers from reaching fall hazards by limiting mobility, offering a proactive approach to fall safety. These systems typically include a body harness connected to a fixed anchorage with a lanyard or restraint line, ensuring users remain within safe zones. Unlike fall arrest harnesses that intervene after a fall occurs, fall restraint systems prioritize hazard avoidance, reducing risk in construction, maintenance, and industrial environments.

Key Differences: Fall Arrest vs Fall Restraint

Fall arrest harnesses are designed to stop a fall after it occurs by absorbing the impact force, whereas fall restraint systems prevent workers from reaching fall hazards altogether by restricting movement. Fall arrest systems require proper anchorage, energy absorbers, and full-body harnesses to minimize injury during a fall, while fall restraint relies on positioning devices or restricted lanyard lengths to eliminate fall risk. Understanding these key differences ensures appropriate safety equipment selection based on specific workplace hazards and compliance with OSHA standards.

When to Use Fall Arrest Harnesses

Fall arrest harnesses are essential when working at heights where there is a risk of falling despite preventive measures, providing a controlled and safe descent during a fall. They are used in construction, tower climbing, and confined space entry where fall hazards cannot be fully eliminated. These harnesses meet OSHA and ANSI standards for impact force reduction and need to be properly fitted, inspected, and connected to an approved anchorage point to ensure maximum protection.

Ideal Applications for Fall Restraint Systems

Fall restraint systems are ideal for environments where workers operate near edges or elevated platforms without the risk of free-fall, such as roofing, window washing, or equipment maintenance on flat surfaces. These systems prevent users from reaching fall hazards by limiting their movement, making them suitable for tasks requiring mobility without the need for fall arrest after a fall occurs. Their design reduces the need for complex rescue procedures, enhancing safety and efficiency in controlled work zones.

Safety Standards and Regulations Comparison

Fall arrest harnesses and fall restraint systems are governed by stringent safety standards such as OSHA 1926.502 and ANSI/ASSE Z359 in the United States, ensuring reliable protection in construction and industrial environments. Fall arrest harnesses must meet specific criteria for impact force absorption, while fall restraint systems focus on preventing workers from reaching fall hazards, adhering to different load and connection requirements. Compliance with these regulations minimizes risk and legally mandates proper equipment use based on task and fall exposure.

Comfort and Mobility Considerations

Fall arrest harnesses often feature adjustable straps and padded materials designed to enhance comfort during prolonged use but may restrict mobility due to their bulkier design and load-bearing components. Fall restraint systems prioritize mobility by limiting the worker's reach, allowing greater freedom of movement with minimal harness bulk, though they may compromise some comfort aspects in situations requiring extended wear. Selecting between the two requires balancing the ergonomic fit and ease of motion against the specific safety requirements and duration of use in fall protection scenarios.

Risk Assessment: Choosing the Right System

Risk assessment is crucial when selecting between fall arrest harnesses and fall restraint systems, as it determines the level of fall risk and the appropriate protective measures. Fall arrest harnesses are designed to stop a fall in progress, requiring thorough analysis of potential fall hazards, free fall distance, and clearance below the worker. Fall restraint systems prevent workers from reaching fall hazards altogether, making them suitable for environments with controlled access and lower fall risk probability.

Maintenance and Inspection Requirements

Fall arrest harnesses require rigorous and frequent inspections to ensure that all buckles, straps, and attachment points remain intact and free from wear, corrosion, or damage to maintain safety compliance. Fall restraint systems demand regular checks on anchorage connectors, lanyards, and harness components to prevent system failure by identifying signs of degradation or mechanical issues early. Proper documentation of inspections and maintenance activities is critical for both systems to guarantee reliability and worker protection from fall hazards.

Cost Implications and ROI Analysis

Fall arrest harnesses typically involve higher initial costs due to more complex materials and certification requirements, but they provide critical protection in high-risk environments, potentially reducing costly injury-related liabilities. Fall restraint systems often cost less upfront as they prevent employees from reaching fall hazards altogether, leading to fewer incidents and less downtime, enhancing operational efficiency. ROI analysis shows that while fall arrest harnesses can increase long-term safety compliance expenses, fall restraint systems offer quicker returns through reduced accident rates and maintenance costs.

Fall arrest harnesses vs Fall restraint systems Infographic

productdif.com

productdif.com