Chemical splash goggles provide a secure seal around the eyes to protect against hazardous liquid splashes and harmful fumes, making them essential for handling chemicals safely. Impact goggles are designed with robust, shatter-resistant lenses to guard against flying debris and physical impacts during mechanical or construction work. Choosing the right goggles depends on the specific safety hazards faced, ensuring optimal eye protection in various environments.

Table of Comparison

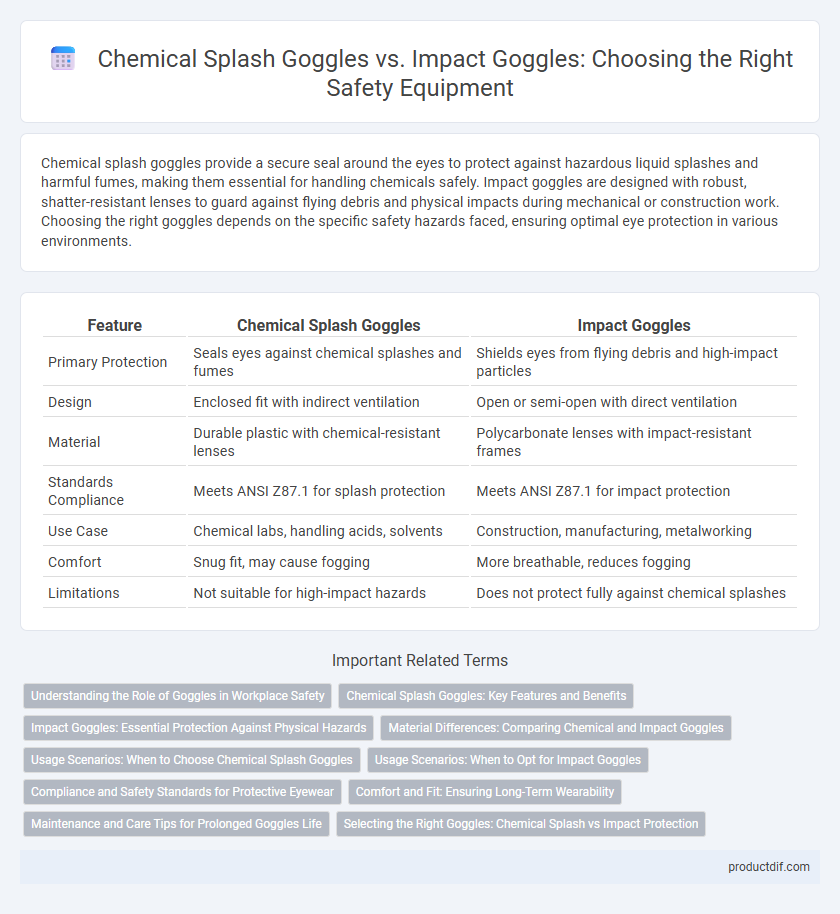

| Feature | Chemical Splash Goggles | Impact Goggles |

|---|---|---|

| Primary Protection | Seals eyes against chemical splashes and fumes | Shields eyes from flying debris and high-impact particles |

| Design | Enclosed fit with indirect ventilation | Open or semi-open with direct ventilation |

| Material | Durable plastic with chemical-resistant lenses | Polycarbonate lenses with impact-resistant frames |

| Standards Compliance | Meets ANSI Z87.1 for splash protection | Meets ANSI Z87.1 for impact protection |

| Use Case | Chemical labs, handling acids, solvents | Construction, manufacturing, metalworking |

| Comfort | Snug fit, may cause fogging | More breathable, reduces fogging |

| Limitations | Not suitable for high-impact hazards | Does not protect fully against chemical splashes |

Understanding the Role of Goggles in Workplace Safety

Chemical splash goggles provide a secure seal around the eyes to protect against hazardous liquid splashes, fumes, and vapors commonly encountered in laboratories and industrial settings. Impact goggles are designed with reinforced, shatter-resistant lenses and robust frames to shield eyes from flying debris, dust, and impact hazards during construction or manufacturing tasks. Both types of goggles are essential in workplace safety programs, ensuring compliance with OSHA regulations and preventing eye injuries by addressing specific environmental risks.

Chemical Splash Goggles: Key Features and Benefits

Chemical splash goggles provide a secure seal around the eyes, preventing harmful liquids and vapors from making contact. They are constructed with durable, chemical-resistant materials that ensure long-lasting protection in laboratory and industrial environments. These goggles often include indirect ventilation to minimize fogging while maintaining a barrier against splashes, enhancing both safety and comfort.

Impact Goggles: Essential Protection Against Physical Hazards

Impact goggles provide essential protection against physical hazards by offering a secure barrier against flying debris, dust, and other particles that can cause eye injuries. Designed with durable materials and reinforced lenses, these goggles meet stringent safety standards such as ANSI Z87.1, ensuring reliable defense during industrial or construction activities. Unlike chemical splash goggles, impact goggles prioritize resistance to mechanical impacts, making them critical for environments with high risks of blunt force trauma.

Material Differences: Comparing Chemical and Impact Goggles

Chemical splash goggles are typically made from flexible materials like PVC or rubber with polycarbonate lenses to form a tight seal against liquids and vapors, providing comprehensive protection against chemical splashes. Impact goggles use rigid, high-impact resistant materials such as polycarbonate or acetate lenses combined with sturdy frames designed to withstand mechanical forces and flying debris. The primary material distinction lies in chemical goggles prioritizing liquid impermeability and comfort for extended wear, while impact goggles focus on impact absorption and durability against physical hazards.

Usage Scenarios: When to Choose Chemical Splash Goggles

Chemical splash goggles are essential when working with hazardous liquids, acids, or solvents that pose risks of splashes and vapors entering the eyes. These goggles provide a tight seal around the eyes, offering superior protection against chemical splashes compared to impact goggles, which are designed primarily for protection from flying debris and physical impacts. Use chemical splash goggles in laboratories, manufacturing, and cleaning operations involving corrosive substances to ensure maximal eye safety.

Usage Scenarios: When to Opt for Impact Goggles

Impact goggles are essential for scenarios involving flying debris, dust, or particles, such as woodworking, metal grinding, and construction work, where protection against high-velocity impacts is critical. These goggles provide a secure seal and robust lens material designed to withstand mechanical hazards, making them ideal for environments with airborne projectiles. For chemical exposure, however, splash goggles remain the preferred choice, as they offer comprehensive coverage against liquid splashes and vapors.

Compliance and Safety Standards for Protective Eyewear

Chemical splash goggles meet ANSI Z87.1-2020 standards for liquid splash protection, ensuring a secure seal and resistance to chemical penetration, crucial in hazardous environments. Impact goggles also comply with ANSI Z87.1-2020, providing high-velocity impact resistance through durable polycarbonate lenses, essential for environments with flying debris. Selecting protective eyewear requires understanding these standards to maintain OSHA compliance and maximize safety against specific workplace hazards.

Comfort and Fit: Ensuring Long-Term Wearability

Chemical splash goggles feature a flexible, contoured design with adjustable straps and soft sealing materials that provide a secure and comfortable fit, minimizing pressure points during extended use. Impact goggles often include cushioned frames and ventilation systems to enhance breathability and reduce fogging, promoting comfort for prolonged wear. Both types prioritize ergonomic construction to ensure user safety without compromising all-day comfort in hazardous environments.

Maintenance and Care Tips for Prolonged Goggles Life

Chemical splash goggles require regular cleaning with mild soap and water to remove chemical residues and prevent lens damage, while impact goggles should be inspected frequently for cracks or scratches that compromise protection. Both types benefit from proper storage in a clean, dry place away from direct sunlight and extreme temperatures to maintain lens clarity and frame integrity. Replacing worn-out straps and ensuring ventilation ports are free of debris further extend the effective lifespan of these safety goggles.

Selecting the Right Goggles: Chemical Splash vs Impact Protection

Selecting the right safety goggles depends on the specific hazards present: chemical splash goggles provide a sealed barrier around the eyes to guard against liquid chemicals and hazardous vapors, while impact goggles are designed with durable materials and reinforced lenses to protect against flying debris and blunt force. Chemical splash goggles meet ANSI Z87.1 standards for splash protection and are essential in laboratories or environments handling corrosive substances. Impact goggles, which also comply with ANSI Z87.1 for impact resistance, are ideal for construction, manufacturing, and other settings where particle impact risks are high.

Chemical splash goggles vs Impact goggles Infographic

productdif.com

productdif.com