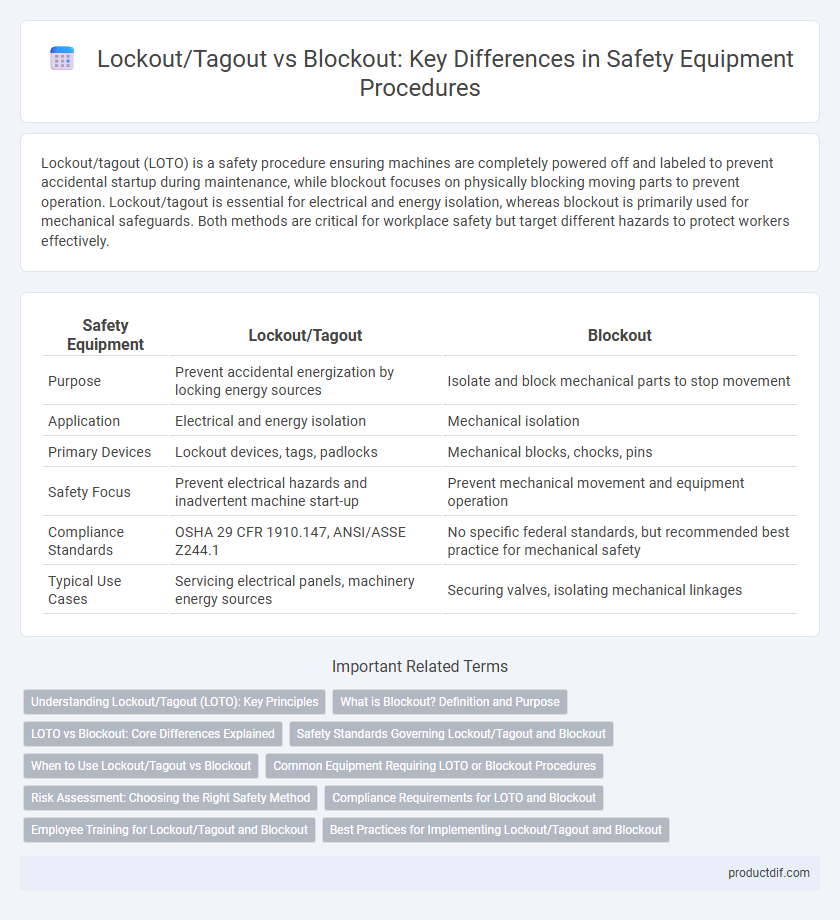

Lockout/tagout (LOTO) is a safety procedure ensuring machines are completely powered off and labeled to prevent accidental startup during maintenance, while blockout focuses on physically blocking moving parts to prevent operation. Lockout/tagout is essential for electrical and energy isolation, whereas blockout is primarily used for mechanical safeguards. Both methods are critical for workplace safety but target different hazards to protect workers effectively.

Table of Comparison

| Safety Equipment | Lockout/Tagout | Blockout |

|---|---|---|

| Purpose | Prevent accidental energization by locking energy sources | Isolate and block mechanical parts to stop movement |

| Application | Electrical and energy isolation | Mechanical isolation |

| Primary Devices | Lockout devices, tags, padlocks | Mechanical blocks, chocks, pins |

| Safety Focus | Prevent electrical hazards and inadvertent machine start-up | Prevent mechanical movement and equipment operation |

| Compliance Standards | OSHA 29 CFR 1910.147, ANSI/ASSE Z244.1 | No specific federal standards, but recommended best practice for mechanical safety |

| Typical Use Cases | Servicing electrical panels, machinery energy sources | Securing valves, isolating mechanical linkages |

Understanding Lockout/Tagout (LOTO): Key Principles

Lockout/Tagout (LOTO) is a critical safety procedure that ensures the complete de-energization and isolation of machinery during maintenance to prevent accidental startup and hazardous energy release. This process involves affixing physical locks and warning tags to energy-isolating devices, guaranteeing that equipment remains in a safe state until authorized personnel remove the lockout devices. Understanding these key principles is essential for minimizing workplace accidents and complying with OSHA safety standards.

What is Blockout? Definition and Purpose

Blockout is a safety procedure used to physically secure energy-isolating devices, preventing accidental machine startup during maintenance by inserting a block or barrier to stop movement. It enhances worker protection by providing a tangible, physical obstruction that complements or serves as an alternative to traditional Lockout/Tagout methods. This method is particularly useful in scenarios where energy sources cannot be fully isolated or locked out but require a clear, physical block to ensure operational safety.

LOTO vs Blockout: Core Differences Explained

Lockout/tagout (LOTO) involves isolating and securing energy sources with locks and tags to prevent accidental machine activation, while blockout uses physical barriers like blocks to prevent movement. LOTO requires a formalized procedure and authorized personnel to apply and remove locks or tags, ensuring energy sources remain controlled during maintenance. Blockout serves as a supplementary safety method, primarily focusing on mechanical isolation rather than energy control.

Safety Standards Governing Lockout/Tagout and Blockout

Safety standards governing Lockout/Tagout (LOTO) are primarily established by OSHA under standard 29 CFR 1910.147, which mandates strict procedures to control hazardous energy during maintenance. Blockout procedures, although less specifically regulated, are often integrated within broader safety protocols and are emphasized in industry consensus standards such as ANSI/ASSE Z244.1-2016 for controlling hazardous energy. Compliance with these standards ensures effective prevention of accidental startup or release of stored energy, enhancing worker safety during equipment servicing.

When to Use Lockout/Tagout vs Blockout

Lockout/tagout should be used when controlling hazardous energy sources during maintenance or servicing of electrical equipment to prevent accidental startup. Blockout is appropriate for mechanical energy isolation, such as securing valves or moving parts, where physical barriers prevent operation. Selecting lockout/tagout or blockout depends on the type of energy and the specific hazards involved in the task.

Common Equipment Requiring LOTO or Blockout Procedures

Common equipment requiring Lockout/Tagout (LOTO) procedures includes electrical panels, circuit breakers, and industrial machinery with hazardous energy sources. Blockout procedures are typically applied to mechanical systems such as valves, pipe flanges, and conveyor belts to physically isolate energy flow. Both LOTO and Blockout methods ensure worker safety by preventing accidental energization during maintenance or repair.

Risk Assessment: Choosing the Right Safety Method

Risk assessment is crucial in determining whether to implement lockout/tagout or blockout procedures, focusing on the specific hazards and energy sources involved. Lockout/tagout provides controlled de-energization for electrical and mechanical systems, ensuring secure isolation and preventing accidental startup. Blockout is often preferred for physical barriers in hydraulic or pneumatic systems where complete energy isolation may be challenging, minimizing risk and enhancing operator safety.

Compliance Requirements for LOTO and Blockout

Lockout/tagout (LOTO) compliance requires employers to follow OSHA standards 29 CFR 1910.147, involving energy control procedures, employee training, and periodic inspections to ensure equipment is de-energized during maintenance. Blockout procedures, while similar in preventing equipment activation, may have different regulatory requirements depending on industry and local regulations but generally emphasize physical barriers and signage. Both methods mandate documented safety protocols, employee authorization, and effective communication to meet legal and workplace safety standards.

Employee Training for Lockout/Tagout and Blockout

Effective employee training for lockout/tagout (LOTO) emphasizes the identification and control of hazardous energy sources through standardized procedures, ensuring machinery remains de-energized during maintenance. Blockout training focuses on physical barriers to isolate equipment, highlighting the importance of secure placement and verification to prevent accidental startup. Comprehensive education on both methods enhances workplace safety by promoting proper application and compliance with OSHA regulations.

Best Practices for Implementing Lockout/Tagout and Blockout

Implementing best practices for lockout/tagout (LOTO) and blockout requires a comprehensive risk assessment to identify all energy sources and establish clear procedures for isolation and verification. Training employees to understand the differences between LOTO, which focuses on energy control via locks and tags, and blockout, which involves physical barriers, ensures effective compliance and hazard prevention. Regular audits and maintenance of equipment, combined with updated documentation, reinforce safety protocols and reduce the risk of accidental energization during maintenance activities.

Lockout/tagout vs Blockout Infographic

productdif.com

productdif.com