Single-gas detectors provide targeted monitoring for one specific hazardous gas, offering simplicity and cost-effectiveness ideal for confined spaces with known risks. Multi-gas detectors enhance safety by simultaneously detecting multiple gases such as oxygen, carbon monoxide, hydrogen sulfide, and combustible gases, making them suitable for diverse environments with varying hazards. Choosing between a single-gas and multi-gas detector depends on the complexity of the work environment and the range of potential gas exposures.

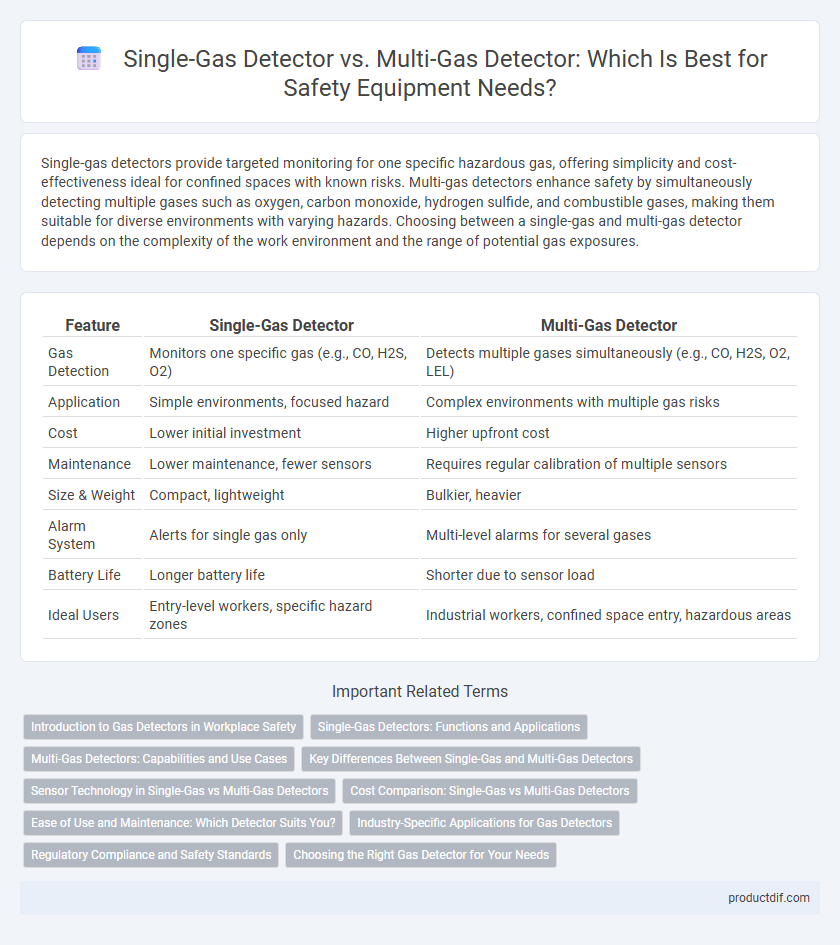

Table of Comparison

| Feature | Single-Gas Detector | Multi-Gas Detector |

|---|---|---|

| Gas Detection | Monitors one specific gas (e.g., CO, H2S, O2) | Detects multiple gases simultaneously (e.g., CO, H2S, O2, LEL) |

| Application | Simple environments, focused hazard | Complex environments with multiple gas risks |

| Cost | Lower initial investment | Higher upfront cost |

| Maintenance | Lower maintenance, fewer sensors | Requires regular calibration of multiple sensors |

| Size & Weight | Compact, lightweight | Bulkier, heavier |

| Alarm System | Alerts for single gas only | Multi-level alarms for several gases |

| Battery Life | Longer battery life | Shorter due to sensor load |

| Ideal Users | Entry-level workers, specific hazard zones | Industrial workers, confined space entry, hazardous areas |

Introduction to Gas Detectors in Workplace Safety

Single-gas detectors are designed to monitor the presence of one specific hazardous gas, providing focused detection for environments with known gas risks such as carbon monoxide or hydrogen sulfide. Multi-gas detectors offer comprehensive safety by simultaneously detecting multiple gases like oxygen, combustible gases, and toxic gases, making them ideal for varied and unpredictable workplace atmospheres. Both devices are critical in industrial safety protocols, helping to prevent exposure to harmful gases and ensuring regulatory compliance.

Single-Gas Detectors: Functions and Applications

Single-gas detectors are designed to monitor one specific hazardous gas, such as carbon monoxide, hydrogen sulfide, or oxygen levels, providing real-time alerts to protect workers in confined spaces or industrial environments. These devices typically offer high sensitivity and quick response times, essential for early hazard detection and prevention of poisoning or asphyxiation incidents. Their compact size and simplicity make them ideal for specialized tasks where monitoring a single gas is critical for safety compliance and risk management.

Multi-Gas Detectors: Capabilities and Use Cases

Multi-gas detectors offer comprehensive monitoring by detecting several hazardous gases simultaneously, commonly including oxygen, carbon monoxide, hydrogen sulfide, and combustible gases. These devices enhance workplace safety in complex environments such as confined spaces, industrial plants, and mining operations by providing real-time alerts for multiple gas hazards. Their advanced sensors and data logging capabilities enable accurate risk assessment and regulatory compliance in environments where exposure to various toxic or combustible gases is possible.

Key Differences Between Single-Gas and Multi-Gas Detectors

Single-gas detectors are designed to monitor the presence of one specific hazardous gas, offering high sensitivity and simplicity for targeted environments such as confined spaces with known gas hazards. Multi-gas detectors simultaneously detect multiple gases, including oxygen levels, combustible gases, and toxic gases, making them ideal for complex industrial settings requiring comprehensive safety monitoring. Key differences include detection scope, complexity, calibration requirements, and cost, with single-gas detectors being more cost-effective and user-friendly, whereas multi-gas detectors provide broader protection and data logging capabilities.

Sensor Technology in Single-Gas vs Multi-Gas Detectors

Single-gas detectors typically utilize electrochemical sensors designed to detect a specific gas with high sensitivity and faster response times, making them ideal for targeted monitoring. Multi-gas detectors incorporate multiple sensor types, such as electrochemical, infrared, and catalytic bead sensors, to simultaneously monitor various hazardous gases in complex environments. Sensor technology advancements in multi-gas detectors enhance cross-sensitivity compensation and data integration, improving overall detection accuracy and safety compliance.

Cost Comparison: Single-Gas vs Multi-Gas Detectors

Single-gas detectors generally have a lower upfront cost compared to multi-gas detectors, making them ideal for monitoring one specific hazard such as carbon monoxide or oxygen levels. Multi-gas detectors, while more expensive initially, offer the advantage of detecting multiple hazardous gases simultaneously, potentially reducing the need for multiple devices in complex environments. Over time, multi-gas detectors can provide cost savings through centralized monitoring, lower maintenance, and enhanced safety coverage.

Ease of Use and Maintenance: Which Detector Suits You?

Single-gas detectors offer straightforward operation and minimal maintenance, ideal for users seeking simplicity and quick deployment in environments with known hazards. Multi-gas detectors, while slightly more complex, provide comprehensive monitoring of multiple gases simultaneously, requiring regular sensor calibration and battery checks to ensure accuracy. Choosing between the two depends on the specific safety requirements and the user's capacity for routine upkeep and device management.

Industry-Specific Applications for Gas Detectors

Single-gas detectors are ideal for industries like confined space entry, where monitoring a specific hazardous gas such as oxygen or hydrogen sulfide is critical. Multi-gas detectors find extensive use in industries like oil and gas, mining, and chemical manufacturing, where simultaneous detection of multiple gases like methane, carbon monoxide, oxygen, and hydrogen sulfide ensures comprehensive worker safety. Choosing the appropriate gas detector depends on the specific risk profile and regulatory requirements of the industry, optimizing safety compliance and operational efficiency.

Regulatory Compliance and Safety Standards

Single-gas detectors are designed to monitor a specific hazardous gas, often meeting regulatory requirements for confined space entry or specific industry standards such as OSHA or NIOSH. Multi-gas detectors comply with broader safety regulations by simultaneously detecting multiple gases like oxygen, carbon monoxide, hydrogen sulfide, and combustible gases, ensuring comprehensive workplace safety. Compliance with standards such as ANSI, CSA, and ATEX is critical in selecting suitable detectors to maintain regulatory adherence and protect worker health effectively.

Choosing the Right Gas Detector for Your Needs

Single-gas detectors are ideal for monitoring a specific hazardous gas, offering targeted detection with high sensitivity and longer battery life, making them suitable for environments with known, consistent risks. Multi-gas detectors provide comprehensive safety by simultaneously detecting multiple gases, such as oxygen, carbon monoxide, hydrogen sulfide, and combustible gases, which is essential in complex industrial settings with varied hazards. Selecting the right gas detector depends on the specific application, gas types present, regulatory requirements, and the user's need for portability or advanced features like data logging and real-time alerts.

single-gas detector vs multi-gas detector Infographic

productdif.com

productdif.com