Type I hard hats provide protection from impacts to the top of the head, making them ideal for environments with falling object hazards. Type II hard hats offer enhanced protection against lateral impacts and side blows, suitable for more complex work settings where side impacts are a risk. Choosing the correct type of hard hat ensures optimal safety and compliance with industry regulations for pet safety equipment.

Table of Comparison

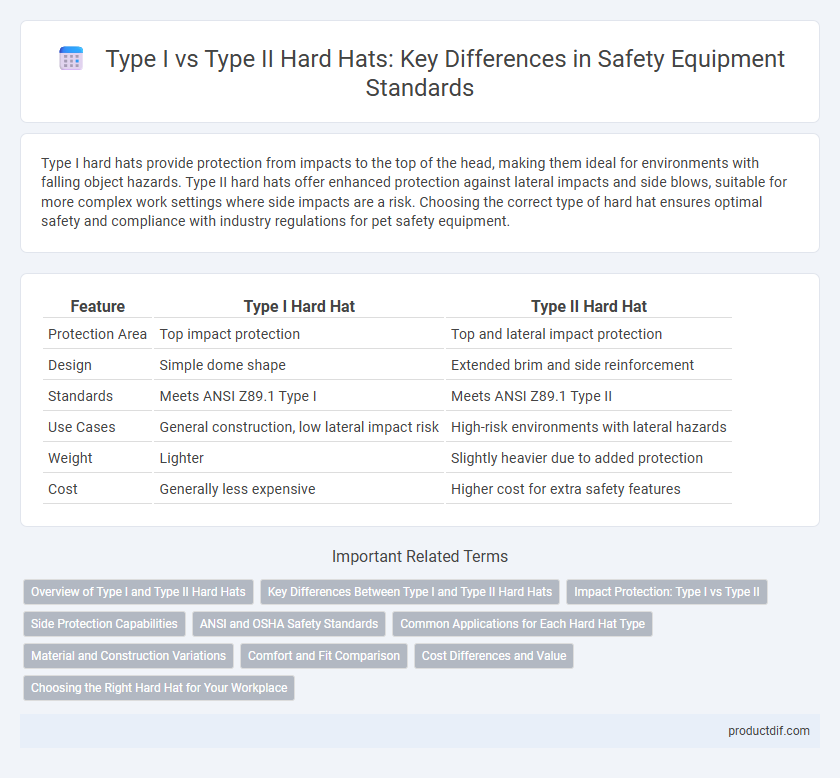

| Feature | Type I Hard Hat | Type II Hard Hat |

|---|---|---|

| Protection Area | Top impact protection | Top and lateral impact protection |

| Design | Simple dome shape | Extended brim and side reinforcement |

| Standards | Meets ANSI Z89.1 Type I | Meets ANSI Z89.1 Type II |

| Use Cases | General construction, low lateral impact risk | High-risk environments with lateral hazards |

| Weight | Lighter | Slightly heavier due to added protection |

| Cost | Generally less expensive | Higher cost for extra safety features |

Overview of Type I and Type II Hard Hats

Type I hard hats provide impact protection primarily to the top of the head and are commonly used in construction and industrial environments where falling objects are a major hazard. Type II hard hats offer enhanced protection, covering both top and lateral impacts to the head, making them suitable for jobs with risks of side impacts such as electrical work or arboriculture. Both types meet ANSI/ISEA Z89.1 standards but differ primarily in design and side-impact protection capabilities.

Key Differences Between Type I and Type II Hard Hats

Type I hard hats provide protection primarily from impacts to the top of the head, designed for vertical protection against falling objects common on construction sites. Type II hard hats offer lateral as well as vertical impact protection, featuring additional cushioning and suspension systems to reduce shock from side impacts. Both types meet strict ANSI/ISEA standards, but Type II is preferred in environments with potential for side hazards.

Impact Protection: Type I vs Type II

Type I hard hats provide impact protection primarily from vertical forces, designed to safeguard against falling objects hitting the top of the head. Type II hard hats offer enhanced protection against both vertical and lateral impacts by incorporating additional foam or suspension elements on the sides. OSHA standards recognize Type II helmets as suitable for workplaces where multi-directional impact hazards are present, making them essential for environments with side and top impact risks.

Side Protection Capabilities

Type I hard hats provide impact protection primarily from falling objects directly above, whereas Type II hard hats offer enhanced side impact protection designed to safeguard against lateral blows and penetration hazards. The side protection capabilities of Type II hard hats include reinforced lateral coverage and cushioning to reduce the risk of head injuries from angled or side impacts. OSHA standards specify Type II hard hats for work environments where side impacts are a significant risk, ensuring comprehensive head protection.

ANSI and OSHA Safety Standards

Type I hard hats are designed primarily to protect against impact from falling objects, meeting ANSI Z89.1-2014 Type I standards and OSHA regulations 29 CFR 1910.135 for head protection in workplaces. Type II hard hats provide protection from both top and lateral impacts, adhering to stricter ANSI Z89.1 Type II criteria and OSHA mandates for environments with side impact risks. Selecting the appropriate hard hat type ensures compliance with safety standards and optimizes protection based on specific job site hazards.

Common Applications for Each Hard Hat Type

Type I hard hats are commonly used in construction and industrial settings where risks involve impact from falling objects directly above the head. Type II hard hats are preferred in industries such as manufacturing, electrical work, and road maintenance, offering enhanced protection against lateral impacts and side blows. Each type is designed to meet specific safety standards tailored to the hazards typically encountered in these environments.

Material and Construction Variations

Type I hard hats are designed primarily for top impact protection and typically feature a rigid suspension system made from high-density polyethylene (HDPE) or fiberglass, providing excellent durability and resistance against falling objects. Type II hard hats incorporate additional lateral impact protection with enhanced internal cushioning and a thicker shell often constructed from advanced composite materials such as polycarbonate or reinforced fiberglass, offering superior shock absorption and side-impact defense. Variations in material and construction between Type I and Type II hard hats directly influence their protective capabilities and suitability for different work environments requiring specific impact resistance standards.

Comfort and Fit Comparison

Type I hard hats prioritize impact protection from above, often featuring a more rigid suspension system that can feel heavier and less comfortable over long periods. Type II hard hats are designed with lateral impact protection and typically include additional padding and adjustable suspension, offering improved fit and enhanced comfort for extended wear. Ergonomic design variations in Type II helmets often result in better weight distribution and reduced pressure points compared to Type I models.

Cost Differences and Value

Type I hard hats generally cost less due to their simple design focused on top impact protection, making them a budget-friendly option for many workplaces. Type II hard hats provide enhanced protection against side impacts and lateral forces, which results in higher manufacturing costs and a higher price point. Investing in Type II hard hats often delivers greater value on job sites with comprehensive hazard exposure, balancing cost differences with improved safety performance.

Choosing the Right Hard Hat for Your Workplace

Type I hard hats provide top impact protection and are ideal for workplaces with falling object hazards from above, such as construction sites. Type II hard hats offer both top and lateral impact protection, making them suitable for environments with risks from side impacts like electrical or industrial settings. Selecting the right hard hat depends on evaluating specific workplace hazards to ensure optimal head protection and compliance with OSHA and ANSI standards.

Type I hard hat vs Type II hard hat Infographic

productdif.com

productdif.com