ANSI and EN standards both regulate safety equipment for pets, ensuring quality and reliability, but they differ in regional applicability and specific requirements. ANSI standards are predominantly used in the United States, focusing on performance and safety benchmarks tailored to American regulations. EN standards, established by the European Committee for Standardization, provide harmonized criteria across Europe, emphasizing durability and safety under European conditions.

Table of Comparison

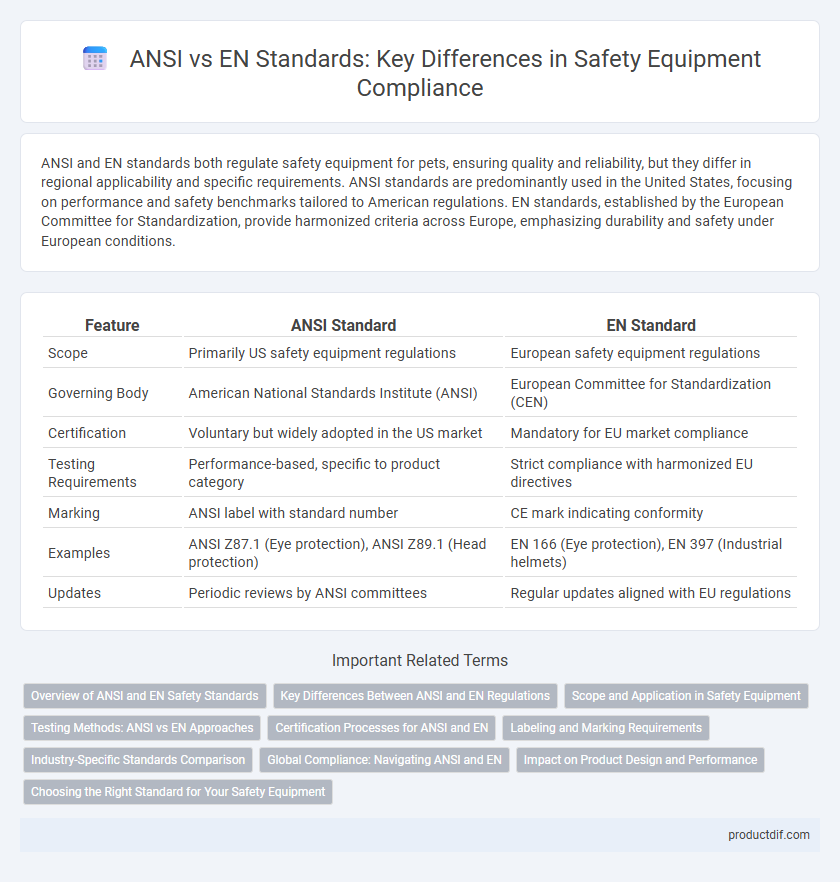

| Feature | ANSI Standard | EN Standard |

|---|---|---|

| Scope | Primarily US safety equipment regulations | European safety equipment regulations |

| Governing Body | American National Standards Institute (ANSI) | European Committee for Standardization (CEN) |

| Certification | Voluntary but widely adopted in the US market | Mandatory for EU market compliance |

| Testing Requirements | Performance-based, specific to product category | Strict compliance with harmonized EU directives |

| Marking | ANSI label with standard number | CE mark indicating conformity |

| Examples | ANSI Z87.1 (Eye protection), ANSI Z89.1 (Head protection) | EN 166 (Eye protection), EN 397 (Industrial helmets) |

| Updates | Periodic reviews by ANSI committees | Regular updates aligned with EU regulations |

Overview of ANSI and EN Safety Standards

ANSI (American National Standards Institute) and EN (European Norm) standards govern safety equipment to ensure protection and compliance across regions. ANSI standards are widely adopted in the United States, focusing on stringent performance criteria and workplace safety regulations. EN standards, established by the European Committee for Standardization, emphasize harmonized safety requirements across European countries, facilitating international product acceptance and uniform safety measures.

Key Differences Between ANSI and EN Regulations

ANSI standards primarily apply to safety equipment in the United States and emphasize rigorous testing protocols specific to American workplace environments. EN regulations, governed by the European Committee for Standardization, focus on harmonizing safety requirements across European Union member countries, prioritizing conformity with diverse industrial sectors. Key differences include regional applicability, testing methods, certification processes, and performance criteria tailored to meet distinct safety challenges.

Scope and Application in Safety Equipment

ANSI standards primarily serve the United States market, focusing on occupational safety equipment such as helmets, gloves, and eye protection designed for specific industry needs. EN standards, established by the European Committee for Standardization, offer a harmonized framework across Europe that addresses a broader range of safety equipment, including fall protection, respiratory devices, and hearing protection, ensuring compliance with EU regulations. While ANSI emphasizes compliance with US workplace safety regulations, EN standards integrate environmental and ergonomic factors, making them crucial for products sold in the European Economic Area.

Testing Methods: ANSI vs EN Approaches

ANSI safety equipment testing methods emphasize rigorous impact and penetration resistance tests specific to North American hazards, ensuring compliance with OSHA regulations. EN standards adopt a more comprehensive approach, incorporating environmental and ergonomic assessments alongside mechanical performance, reflecting diverse European workplace conditions. Both frameworks apply dynamic and static testing protocols, but EN often requires more extensive certification involving third-party evaluations across multiple safety parameters.

Certification Processes for ANSI and EN

ANSI certification requires rigorous testing based on American national standards, involving third-party laboratories that evaluate safety equipment performance under controlled conditions. EN certification follows European harmonized standards through the CE marking process, which mandates conformity assessment by notified bodies or manufacturers' self-declaration depending on product risk category. The ANSI process emphasizes compliance with specific test methods and performance criteria, while EN certification focuses on meeting essential health and safety requirements defined by the European Union.

Labeling and Marking Requirements

ANSI safety equipment labeling mandates clear, durable markings including manufacturer identification, model number, and compliance date to ensure traceability and user safety, adhering to ANSI Z535 standards. EN standards require comprehensive labeling with pictograms, safety instructions in multiple languages, and CE marking to demonstrate conformity with European directives, enhancing cross-border user understanding. Both standards emphasize legible, weather-resistant labels but differ in regulatory scope and specific informational demands tailored to regional safety protocols.

Industry-Specific Standards Comparison

ANSI and EN standards differ significantly in their approach to safety equipment, with ANSI primarily serving the U.S. market and emphasizing industry-specific performance criteria tailored to North American regulations. EN standards, governed by the European Committee for Standardization (CEN), provide a harmonized framework across Europe focusing on international safety benchmarks suited for various industries such as construction, manufacturing, and healthcare. Comparing these standards reveals that while ANSI standards often cater to specialized sectors with detailed testing protocols, EN standards prioritize broader compliance and interoperability within the European Economic Area.

Global Compliance: Navigating ANSI and EN

ANSI and EN standards serve as critical benchmarks for safety equipment certification, with ANSI primarily governing the United States and EN standards widely adopted across Europe and other global markets. Understanding the differences between ANSI Z87.1 for eye and face protection and EN 166 for personal eye protection helps manufacturers ensure equipment meets region-specific regulatory requirements. Achieving dual compliance with ANSI and EN standards enhances global market access, ensuring safety products fulfill diverse international safety and performance criteria.

Impact on Product Design and Performance

ANSI and EN standards significantly influence safety equipment design by setting distinct criteria for impact resistance, material durability, and testing methods. ANSI standards often emphasize specific performance metrics like impact force thresholds, while EN standards integrate comprehensive assessments including shock absorption and distribution. Compliance with these standards ensures optimized product performance tailored to regional safety regulations and user protection requirements.

Choosing the Right Standard for Your Safety Equipment

Selecting the appropriate safety equipment standard depends on the regional requirements and specific industry applications. ANSI standards, predominantly used in the United States, emphasize detailed testing procedures and performance criteria tailored for American workplace environments, while EN standards, adopted across Europe, focus on harmonized safety requirements to ensure product compatibility within the EU market. Understanding the regulatory frameworks and performance benchmarks of ANSI and EN is crucial for ensuring compliance and maximizing protection in varied occupational settings.

ANSI vs EN standards Infographic

productdif.com

productdif.com