Personal Protective Equipment (PPE) for pets primarily includes items like protective clothing, gloves, and boots designed to prevent injury from environmental hazards. Respiratory Protective Equipment (RPE) specifically protects pets from inhaling harmful substances such as smoke, dust, or chemicals, often including masks or respirators tailored for animals. Choosing the appropriate safety equipment depends on the nature of the hazard pet owners expect to encounter, ensuring both physical protection and respiratory safety.

Table of Comparison

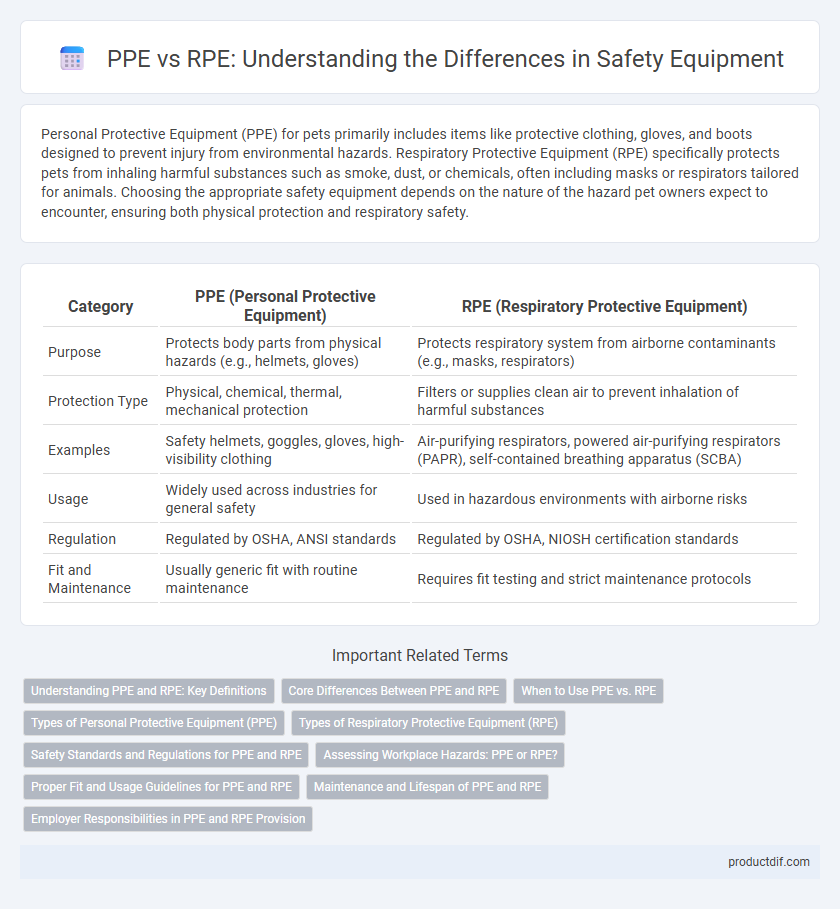

| Category | PPE (Personal Protective Equipment) | RPE (Respiratory Protective Equipment) |

|---|---|---|

| Purpose | Protects body parts from physical hazards (e.g., helmets, gloves) | Protects respiratory system from airborne contaminants (e.g., masks, respirators) |

| Protection Type | Physical, chemical, thermal, mechanical protection | Filters or supplies clean air to prevent inhalation of harmful substances |

| Examples | Safety helmets, goggles, gloves, high-visibility clothing | Air-purifying respirators, powered air-purifying respirators (PAPR), self-contained breathing apparatus (SCBA) |

| Usage | Widely used across industries for general safety | Used in hazardous environments with airborne risks |

| Regulation | Regulated by OSHA, ANSI standards | Regulated by OSHA, NIOSH certification standards |

| Fit and Maintenance | Usually generic fit with routine maintenance | Requires fit testing and strict maintenance protocols |

Understanding PPE and RPE: Key Definitions

Personal Protective Equipment (PPE) encompasses a broad range of gear designed to protect workers from physical, chemical, biological, and ergonomic hazards, including gloves, helmets, and protective clothing. Respiratory Protective Equipment (RPE) is a specialized subset of PPE focused exclusively on safeguarding the wearer's respiratory system from harmful airborne contaminants such as dust, fumes, vapors, and gases. Understanding the distinction between PPE and RPE is critical for selecting the appropriate safety equipment to mitigate specific workplace hazards effectively.

Core Differences Between PPE and RPE

Personal Protective Equipment (PPE) encompasses a broad range of gear designed to protect the entire body from hazards, including gloves, helmets, and eye protection. Respiratory Protective Equipment (RPE) specifically targets the respiratory system, filtering or supplying clean air to prevent inhalation of harmful substances. The core difference lies in their protection focus: PPE offers general defense against physical risks, while RPE is specialized for safeguarding against airborne contaminants.

When to Use PPE vs. RPE

Personal Protective Equipment (PPE) includes items like gloves, helmets, and safety glasses used to protect against general workplace hazards. Respiratory Protective Equipment (RPE) is specifically designed to protect users from inhaling harmful airborne substances and should be used when exposure to dust, fumes, or chemicals is present. Choosing between PPE and RPE depends on the risk assessment of the environment, with RPE required for respiratory hazards and PPE for other physical or chemical risks.

Types of Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) includes a wide range of gear such as gloves, safety goggles, helmets, and protective clothing designed to shield workers from physical, chemical, or biological hazards. Respiratory Protective Equipment (RPE) is a specialized subset of PPE focused exclusively on protecting the respiratory system from airborne contaminants like dust, gases, and fumes. Effective safety protocols require selecting the appropriate types of PPE, including RPE, based on specific workplace hazards to ensure comprehensive protection.

Types of Respiratory Protective Equipment (RPE)

Types of Respiratory Protective Equipment (RPE) include disposable masks, half-face respirators, full-face respirators, and powered air-purifying respirators (PAPRs). Each type offers varying levels of protection against airborne contaminants, with disposable masks suited for low-risk exposure, while full-face respirators provide comprehensive coverage against toxic particles and gases. Selecting appropriate RPE depends on specific workplace hazards, required protection levels, and user comfort.

Safety Standards and Regulations for PPE and RPE

Personal Protective Equipment (PPE) must comply with safety standards such as OSHA 29 CFR 1910 and ANSI Z87.1 for eye protection, while Respiratory Protective Equipment (RPE) adheres to stringent regulations outlined in NIOSH 42 CFR Part 84 and IP Classification standards like NIOSH N95 or P100. Employers are required to implement and maintain PPE and RPE that meet these specific certifications to ensure maximum worker safety and regulatory compliance.

Assessing Workplace Hazards: PPE or RPE?

Assessing workplace hazards involves identifying specific risks such as airborne contaminants or physical impacts to determine appropriate protection. Personal Protective Equipment (PPE) like gloves and helmets shield against physical injuries, while Respiratory Protective Equipment (RPE) specifically safeguards against inhalation hazards from dust, fumes, or gases. Selecting the correct safety equipment requires a thorough hazard assessment to ensure worker safety complies with regulatory standards and effectively mitigates identified risks.

Proper Fit and Usage Guidelines for PPE and RPE

Proper fit is critical for both Personal Protective Equipment (PPE) and Respiratory Protective Equipment (RPE) to ensure maximum protection against workplace hazards. PPE, such as gloves, helmets, and safety glasses, must conform closely to the user's body size and shape to prevent exposure through gaps or slippage, while RPE requires rigorous fit testing and seal checks to maintain an effective barrier against airborne contaminants. Usage guidelines emphasize regular inspection, correct donning and doffing procedures, and adherence to manufacturer specifications to maintain the integrity and performance of both PPE and RPE.

Maintenance and Lifespan of PPE and RPE

Proper maintenance of Personal Protective Equipment (PPE) involves regular inspection, cleaning, and storage to extend its lifespan and ensure optimal performance. Respiratory Protective Equipment (RPE) requires more frequent maintenance, including filter replacement and seal checks, to maintain effective protection against airborne hazards. Neglecting maintenance reduces the durability and protective capabilities of both PPE and RPE, increasing health risks for users.

Employer Responsibilities in PPE and RPE Provision

Employers are legally required to assess workplace hazards and provide appropriate Personal Protective Equipment (PPE) and Respiratory Protective Equipment (RPE) to mitigate risks. Proper selection, fitting, maintenance, and training on PPE and RPE use are essential to ensure employee safety and regulatory compliance. Regular inspections and replacements safeguard effectiveness in protecting workers from physical, chemical, and biological hazards.

PPE vs RPE Infographic

productdif.com

productdif.com