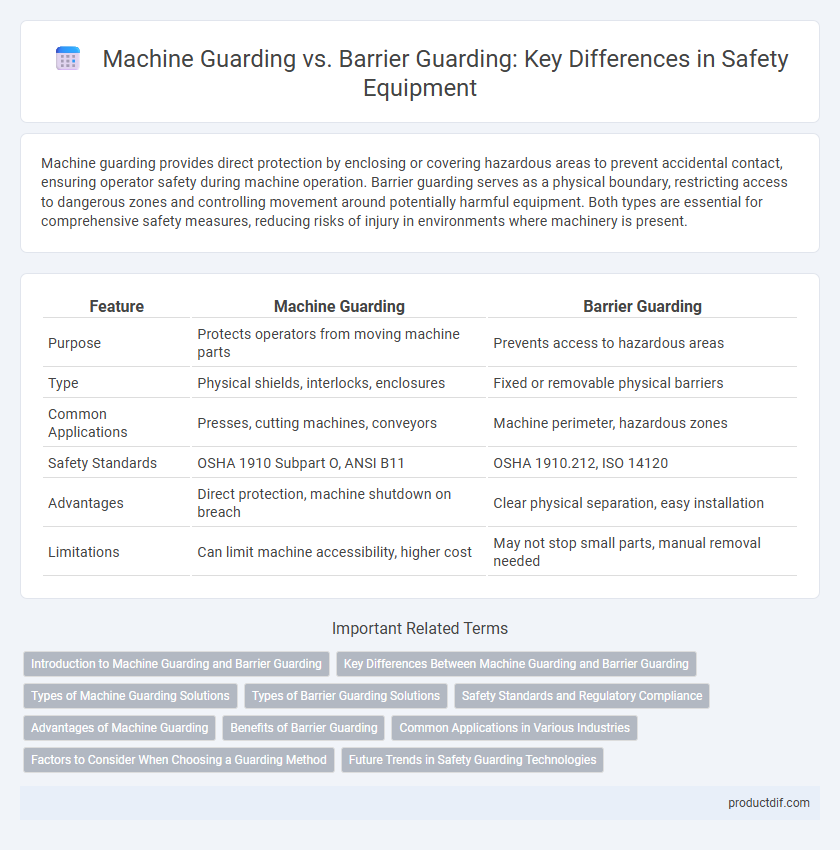

Machine guarding provides direct protection by enclosing or covering hazardous areas to prevent accidental contact, ensuring operator safety during machine operation. Barrier guarding serves as a physical boundary, restricting access to dangerous zones and controlling movement around potentially harmful equipment. Both types are essential for comprehensive safety measures, reducing risks of injury in environments where machinery is present.

Table of Comparison

| Feature | Machine Guarding | Barrier Guarding |

|---|---|---|

| Purpose | Protects operators from moving machine parts | Prevents access to hazardous areas |

| Type | Physical shields, interlocks, enclosures | Fixed or removable physical barriers |

| Common Applications | Presses, cutting machines, conveyors | Machine perimeter, hazardous zones |

| Safety Standards | OSHA 1910 Subpart O, ANSI B11 | OSHA 1910.212, ISO 14120 |

| Advantages | Direct protection, machine shutdown on breach | Clear physical separation, easy installation |

| Limitations | Can limit machine accessibility, higher cost | May not stop small parts, manual removal needed |

Introduction to Machine Guarding and Barrier Guarding

Machine guarding involves physical devices designed to protect operators from moving parts by preventing access to hazardous areas, reducing risks of injury during machine operation. Barrier guarding specifically refers to fixed or adjustable protective barriers that isolate operators from dangerous machine components without interfering with machine functionality. Effective implementation of machine guarding, including barrier guarding, ensures compliance with safety standards such as OSHA and enhances workplace safety by minimizing exposure to mechanical hazards.

Key Differences Between Machine Guarding and Barrier Guarding

Machine guarding involves protective devices integrated directly into machinery to prevent operator contact with hazardous parts, ensuring compliance with OSHA standards. Barrier guarding refers to physical barriers placed around machinery or dangerous areas to restrict access, often used when direct guarding is impractical. Key differences include machine guarding's focus on moving parts protection and barrier guarding's emphasis on perimeter control and space separation for safety.

Types of Machine Guarding Solutions

Machine guarding solutions encompass fixed guards, interlocked guards, adjustable guards, and self-adjusting guards designed to prevent operator contact with hazards. Barrier guarding typically involves physical barriers like fences or walls that restrict access to dangerous machinery areas without direct interaction. Choosing the appropriate machine guarding type depends on the machine operation, risk level, and required flexibility for maintenance and production efficiency.

Types of Barrier Guarding Solutions

Barrier guarding solutions include fixed barriers, interlocked gates, and adjustable barriers designed to prevent unauthorized access to hazardous machine areas. Fixed barriers serve as durable, permanent guards that provide continuous protection, while interlocked gates incorporate safety switches to stop machinery when opened, enhancing worker safety during maintenance. Adjustable barriers offer flexibility, allowing customization for different machine sizes and operational needs, improving overall workplace hazard control.

Safety Standards and Regulatory Compliance

Machine guarding and barrier guarding are essential components of safety equipment that comply with OSHA and ANSI safety standards to prevent workplace injuries. Machine guarding typically involves integrated protective devices that provide direct protection around moving parts, while barrier guarding uses physical separations to restrict access to hazardous areas. Compliance with these regulatory requirements ensures effective risk mitigation and promotes safer working environments in industrial settings.

Advantages of Machine Guarding

Machine guarding offers precise protection by directly enclosing hazardous moving parts, significantly reducing the risk of accidental contact and injury. It enables continuous operation while maintaining a safe environment, minimizing downtime compared to barrier guarding. Machine guards are customizable to fit specific equipment, enhancing safety compliance with OSHA standards and improving overall workplace safety.

Benefits of Barrier Guarding

Barrier guarding provides enhanced protection by physically separating workers from hazardous machine parts, significantly reducing the risk of accidental contact and injuries. It offers flexibility in design, allowing customization to fit various machine sizes and types while maintaining compliance with OSHA safety regulations. Additionally, barrier guards minimize maintenance interruptions by preventing debris and contaminants from reaching critical machine components.

Common Applications in Various Industries

Machine guarding frequently protects workers from moving parts in manufacturing, packaging, and metalworking industries, ensuring compliance with OSHA standards. Barrier guarding is commonly used in automotive assembly lines, food processing plants, and warehouses to restrict access to hazardous zones without impeding workflow. Both methods enhance safety by reducing accident risks in environments with heavy machinery and automated equipment.

Factors to Consider When Choosing a Guarding Method

Selecting the appropriate guarding method depends on factors such as the type of machinery, potential hazards, and workplace layout. Machine guarding offers precise protection by enclosing moving parts, enhancing safety during operation, while barrier guarding provides a physical separation that prevents access without obstructing visibility. Evaluating maintenance requirements, ease of access for cleaning or repairs, and compliance with OSHA standards are essential to optimize worker safety and operational efficiency.

Future Trends in Safety Guarding Technologies

Machine guarding is evolving with the integration of smart sensors and AI-driven monitoring systems that enhance real-time hazard detection and automated shutdowns, significantly reducing workplace injuries. Barrier guarding technology is advancing through the use of modular and transparent materials combined with IoT connectivity, enabling dynamic adjustments and remote monitoring for greater flexibility and compliance. Future safety guarding trends emphasize predictive maintenance and adaptive protection systems that optimize safety protocols while minimizing downtime and operational disruptions.

Machine guarding vs Barrier guarding Infographic

productdif.com

productdif.com