Chemical-resistant boots provide superior protection against hazardous substances and corrosive chemicals, making them essential for environments with exposure to acids, solvents, and other harmful liquids. Steel-toe boots offer robust impact resistance and durability, safeguarding feet from heavy falling objects and compression injuries commonly encountered in construction and industrial settings. Choosing the appropriate safety footwear depends on the specific hazards present, prioritizing chemical protection or mechanical safety to ensure optimal foot safety.

Table of Comparison

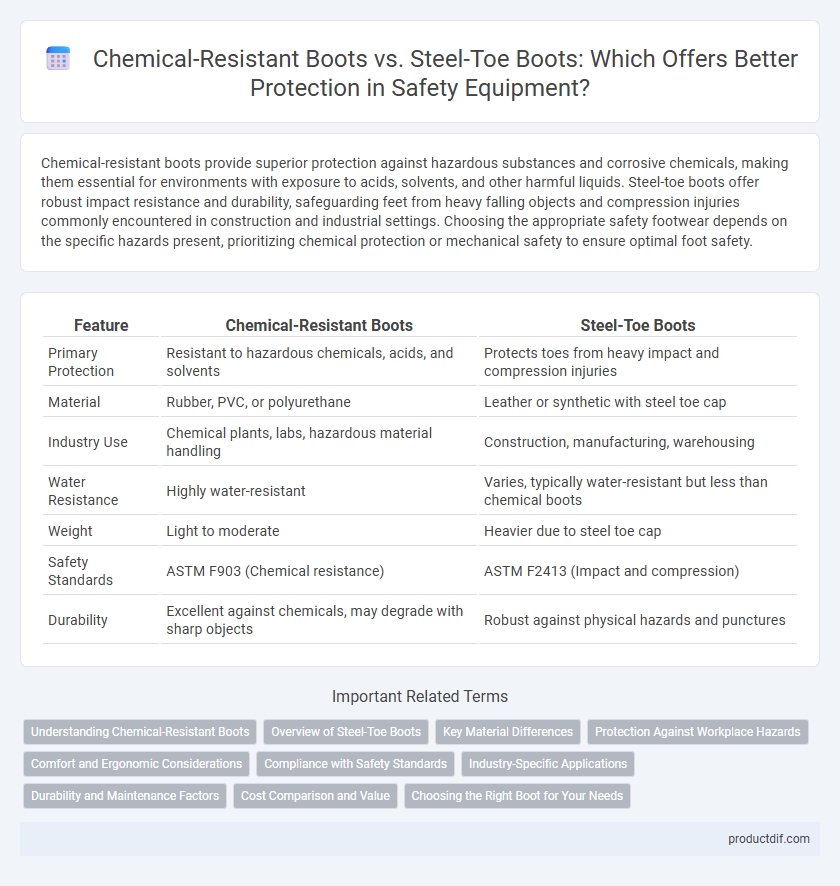

| Feature | Chemical-Resistant Boots | Steel-Toe Boots |

|---|---|---|

| Primary Protection | Resistant to hazardous chemicals, acids, and solvents | Protects toes from heavy impact and compression injuries |

| Material | Rubber, PVC, or polyurethane | Leather or synthetic with steel toe cap |

| Industry Use | Chemical plants, labs, hazardous material handling | Construction, manufacturing, warehousing |

| Water Resistance | Highly water-resistant | Varies, typically water-resistant but less than chemical boots |

| Weight | Light to moderate | Heavier due to steel toe cap |

| Safety Standards | ASTM F903 (Chemical resistance) | ASTM F2413 (Impact and compression) |

| Durability | Excellent against chemicals, may degrade with sharp objects | Robust against physical hazards and punctures |

Understanding Chemical-Resistant Boots

Chemical-resistant boots are designed with materials such as rubber, neoprene, or PVC to provide protection against hazardous chemicals, preventing skin contact and chemical burns in industrial environments. These boots offer impermeability to acids, solvents, and other corrosive substances, making them essential for workers handling toxic liquids or contaminated spills. Unlike steel-toe boots, which primarily protect against impact and compression injuries, chemical-resistant boots prioritize chemical stability and durability under corrosive exposure.

Overview of Steel-Toe Boots

Steel-toe boots feature a reinforced toe cap made from steel, designed to protect the feet from heavy falling objects and compression hazards commonly encountered in construction, manufacturing, and industrial settings. These boots often include slip-resistant soles, durable leather uppers, and waterproof materials, providing comprehensive protection and comfort for hazardous work environments. Their robust design meets safety standards such as ASTM F2413, ensuring reliable impact resistance and puncture protection for workers on demanding job sites.

Key Material Differences

Chemical-resistant boots are typically made from materials like rubber, PVC, or neoprene, offering excellent protection against hazardous chemicals and corrosive substances. Steel-toe boots feature a reinforced steel cap that provides impact and compression protection but generally use leather or synthetic uppers, which may not resist chemical exposure effectively. The key material difference lies in the chemical resistance of rubber or PVC versus the mechanical protection of steel combined with more traditional boot materials.

Protection Against Workplace Hazards

Chemical-resistant boots provide specialized protection against hazardous substances, including acids, solvents, and contaminants, minimizing skin exposure and chemical burns in industrial settings. Steel-toe boots are designed to protect feet from impact and compression injuries caused by heavy falling objects or equipment, making them essential in construction and manufacturing environments. Choosing the appropriate footwear depends on the specific workplace hazards, with chemical-resistant boots offering superior defense against chemical risks and steel-toe boots ensuring mechanical impact protection.

Comfort and Ergonomic Considerations

Chemical-resistant boots offer enhanced comfort through flexible materials that reduce foot fatigue during prolonged use, while steel-toe boots prioritize impact protection often resulting in a stiffer fit. Ergonomic considerations in chemical-resistant boots include slip-resistant soles and lightweight construction, which improve mobility and reduce strain. Steel-toe boots may require additional cushioning and arch support to offset their heavier, rigid design and maintain all-day comfort.

Compliance with Safety Standards

Chemical-resistant boots meet ASTM F2413 and EN ISO 20345 standards specifically for chemical protection, ensuring resilience against hazardous substances like acids and solvents. Steel-toe boots comply with ANSI Z41 and ASTM F2413 standards, emphasizing impact resistance and toe protection against heavy objects or compression. Both types must adhere to OSHA regulations to guarantee workplace safety and regulatory compliance.

Industry-Specific Applications

Chemical-resistant boots provide industry-specific protection by withstanding corrosive substances found in chemical manufacturing, pharmaceutical, and hazardous waste management sectors. Steel-toe boots are optimized for construction, manufacturing, and automotive industries, offering impact resistance against heavy falling objects and compression hazards. Selecting between these boots depends on exposure risks: chemical resistance is crucial in environments handling acids and solvents, while steel-toe boots ensure foot safety in rigorous physical labor settings.

Durability and Maintenance Factors

Chemical-resistant boots provide superior durability against harsh chemicals, oils, and solvents, making them ideal for environments with frequent exposure to hazardous substances. Steel-toe boots offer robust protection against impact and compression, but their durability can diminish if exposed to corrosive materials or prolonged moisture. Maintenance for chemical-resistant boots involves regular cleaning to preserve the integrity of the resistant coating, while steel-toe boots require inspection of the toe cap and sole for damage and rust prevention.

Cost Comparison and Value

Chemical-resistant boots typically cost more than steel-toe boots due to specialized materials designed to withstand harsh chemicals, offering superior protection in hazardous environments. Steel-toe boots, while less expensive, provide essential impact resistance and durability suitable for general industrial use. Investing in chemical-resistant boots delivers greater long-term value for workers exposed to chemical hazards, whereas steel-toe boots offer cost-effective safety for broader applications.

Choosing the Right Boot for Your Needs

Chemical-resistant boots provide superior protection against hazardous substances such as acids, solvents, and corrosive chemicals, making them ideal for environments with high chemical exposure. Steel-toe boots are designed to protect against impact and compression injuries, commonly needed in construction, manufacturing, and heavy industry settings where falling objects or heavy machinery pose a risk. Selecting the right boot depends on assessing workplace hazards, prioritizing chemical resistance or impact protection, and ensuring compliance with relevant safety standards like ASTM F2413.

Chemical-resistant boots vs Steel-toe boots Infographic

productdif.com

productdif.com