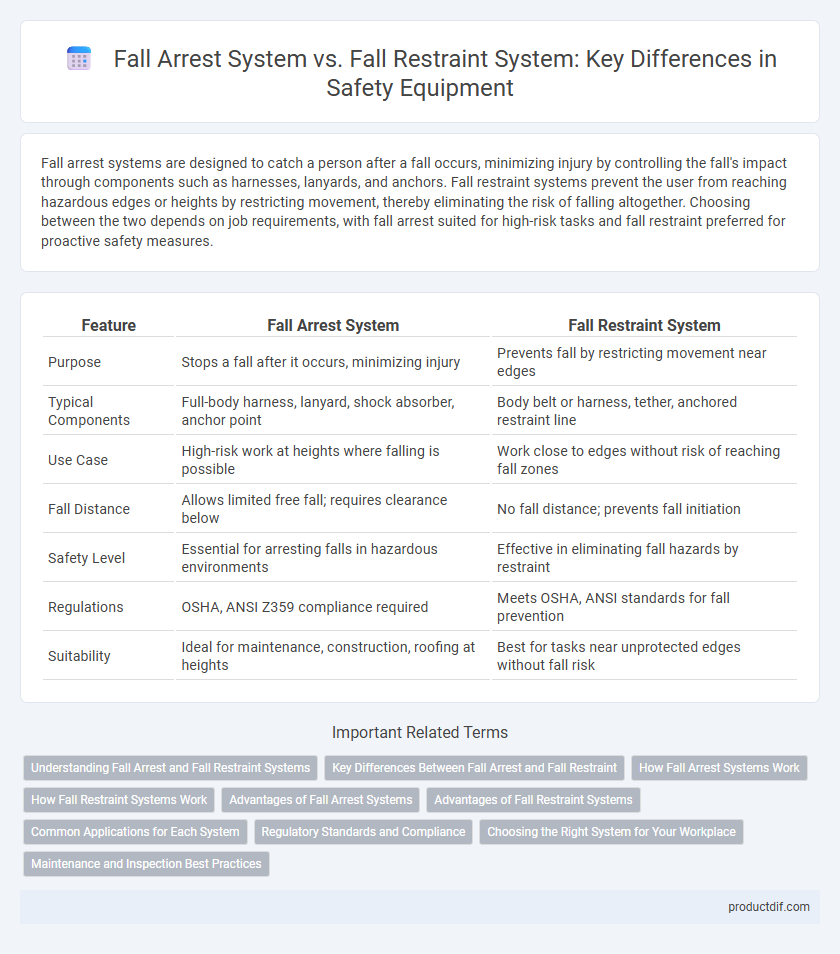

Fall arrest systems are designed to catch a person after a fall occurs, minimizing injury by controlling the fall's impact through components such as harnesses, lanyards, and anchors. Fall restraint systems prevent the user from reaching hazardous edges or heights by restricting movement, thereby eliminating the risk of falling altogether. Choosing between the two depends on job requirements, with fall arrest suited for high-risk tasks and fall restraint preferred for proactive safety measures.

Table of Comparison

| Feature | Fall Arrest System | Fall Restraint System |

|---|---|---|

| Purpose | Stops a fall after it occurs, minimizing injury | Prevents fall by restricting movement near edges |

| Typical Components | Full-body harness, lanyard, shock absorber, anchor point | Body belt or harness, tether, anchored restraint line |

| Use Case | High-risk work at heights where falling is possible | Work close to edges without risk of reaching fall zones |

| Fall Distance | Allows limited free fall; requires clearance below | No fall distance; prevents fall initiation |

| Safety Level | Essential for arresting falls in hazardous environments | Effective in eliminating fall hazards by restraint |

| Regulations | OSHA, ANSI Z359 compliance required | Meets OSHA, ANSI standards for fall prevention |

| Suitability | Ideal for maintenance, construction, roofing at heights | Best for tasks near unprotected edges without fall risk |

Understanding Fall Arrest and Fall Restraint Systems

Fall arrest systems are designed to stop a worker's fall after it has occurred, utilizing components like full-body harnesses, energy absorbers, and anchor points to minimize impact forces and prevent serious injury. In contrast, fall restraint systems prevent workers from reaching fall hazards by restricting their movement with positioning straps or guards, effectively eliminating the risk of a fall. Understanding these systems involves recognizing that fall arrest is reactive, engaging during a fall event, while fall restraint is proactive, preventing falls from happening altogether.

Key Differences Between Fall Arrest and Fall Restraint

Fall arrest systems are designed to stop a worker's fall after it has occurred, using harnesses, lanyards, and shock absorbers to minimize injury. Fall restraint systems prevent workers from reaching a fall hazard by restricting movement, typically utilizing guardrails, body belts, or positioning devices to maintain safe positioning. The key difference lies in fall arrest systems engaging after a fall begins, while fall restraint systems act proactively to prevent falls altogether.

How Fall Arrest Systems Work

Fall arrest systems function by quickly halting a worker's fall through a combination of a full-body harness, a reliable anchor point, and an energy-absorbing lanyard designed to reduce impact forces. These systems activate only after a person begins to fall, allowing limited movement before safely arresting the descent to prevent contact with the ground or obstacles. Fall arrest systems are essential for safeguarding employees working at heights where fall risks cannot be completely eliminated by prevention measures.

How Fall Restraint Systems Work

Fall restraint systems function by preventing workers from reaching hazardous edges where falls might occur, using harnesses, lanyards, and secure anchor points designed to limit movement. These systems rely on precise measurements and adjustable components to ensure the worker's range of motion is restricted before a fall hazard can be encountered. Unlike fall arrest systems that stop falls in progress, fall restraint systems proactively eliminate the risk of falling by maintaining workers within safe zones.

Advantages of Fall Arrest Systems

Fall arrest systems provide critical protection by stopping a worker's fall mid-descent, significantly reducing the risk of serious injury or fatality. These systems allow for greater mobility and flexibility at heights compared to fall restraint systems, enabling users to work safely in diverse environments. Certified components, such as harnesses, lanyards, and energy absorbers, ensure reliable performance and compliance with occupational safety standards.

Advantages of Fall Restraint Systems

Fall restraint systems prevent workers from reaching fall hazards by restricting movement, significantly reducing the risk of falls before they occur. These systems are often easier to install and maintain compared to fall arrest systems, leading to increased efficiency and lower operational costs. By eliminating the potential for falls, fall restraint systems enhance overall workplace safety and compliance with OSHA regulations.

Common Applications for Each System

Fall arrest systems are commonly used in construction, roofing, and maintenance tasks at height where there is a risk of falling from elevated platforms or structures. Fall restraint systems are typically applied in environments like industrial roofing, window washing, and confined space work to prevent workers from reaching fall hazards. Both systems ensure worker protection but are selected based on whether the goal is to stop a fall in progress or to restrict access to fall risks altogether.

Regulatory Standards and Compliance

Fall arrest systems and fall restraint systems must comply with strict regulatory standards such as OSHA 1926, ANSI Z359, and EN 363 to ensure worker safety at elevated heights. Fall arrest systems are designed to stop a fall in progress and require components like full-body harnesses, shock absorbers, and secure anchor points, all meeting specified load and impact criteria. Fall restraint systems prevent workers from reaching fall hazards altogether, demanding precise installation and routine inspections to maintain compliance with safety regulations.

Choosing the Right System for Your Workplace

Selecting the appropriate fall protection system depends on the specific hazards and work environment of your workplace. Fall arrest systems are designed to stop a fall in progress, with components like full-body harnesses, anchor points, and shock-absorbing lanyards, making them ideal for tasks at height where falling is possible. Fall restraint systems prevent workers from reaching fall hazards by restricting movement with equipment such as guardrails, restraint harnesses, and fixed anchors, providing a proactive approach for environments where preventing a fall altogether is crucial.

Maintenance and Inspection Best Practices

Regular maintenance and inspection of fall arrest systems should prioritize checking shock-absorbing lanyards for wear and tear, ensuring anchor points are secure, and verifying the integrity of harness stitching. Fall restraint systems require routine examination of belts, ropes, and hardware for damage and proper functionality to prevent accidental falls effectively. Documenting inspection results and adhering to manufacturer guidelines ensures both systems remain compliant with OSHA and ANSI safety standards.

Fall arrest system vs Fall restraint system Infographic

productdif.com

productdif.com