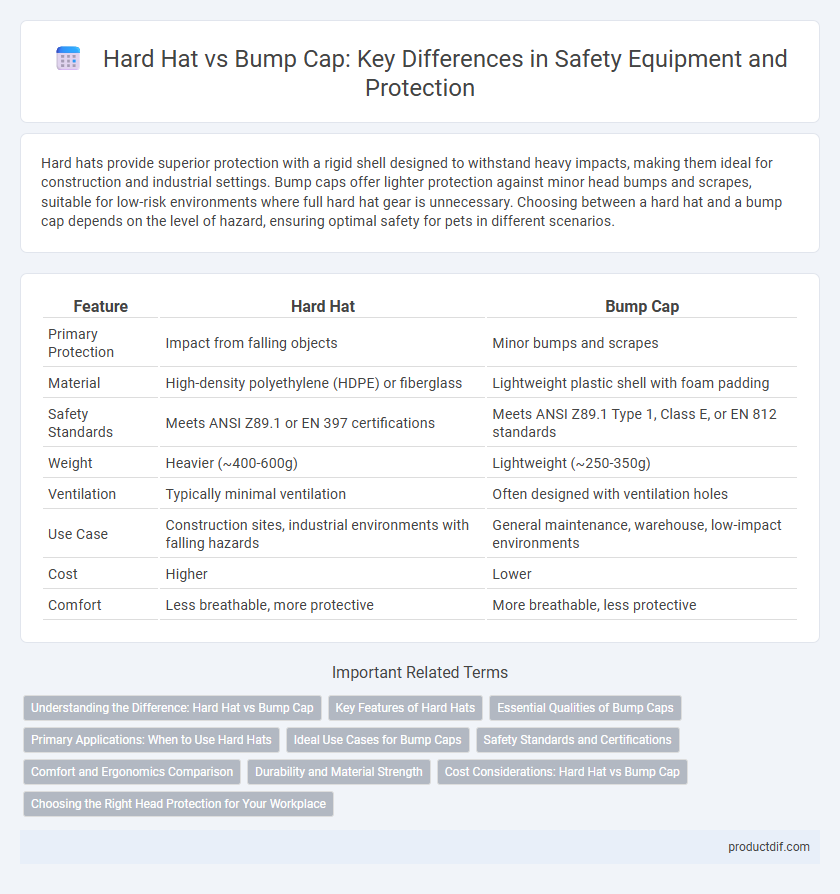

Hard hats provide superior protection with a rigid shell designed to withstand heavy impacts, making them ideal for construction and industrial settings. Bump caps offer lighter protection against minor head bumps and scrapes, suitable for low-risk environments where full hard hat gear is unnecessary. Choosing between a hard hat and a bump cap depends on the level of hazard, ensuring optimal safety for pets in different scenarios.

Table of Comparison

| Feature | Hard Hat | Bump Cap |

|---|---|---|

| Primary Protection | Impact from falling objects | Minor bumps and scrapes |

| Material | High-density polyethylene (HDPE) or fiberglass | Lightweight plastic shell with foam padding |

| Safety Standards | Meets ANSI Z89.1 or EN 397 certifications | Meets ANSI Z89.1 Type 1, Class E, or EN 812 standards |

| Weight | Heavier (~400-600g) | Lightweight (~250-350g) |

| Ventilation | Typically minimal ventilation | Often designed with ventilation holes |

| Use Case | Construction sites, industrial environments with falling hazards | General maintenance, warehouse, low-impact environments |

| Cost | Higher | Lower |

| Comfort | Less breathable, more protective | More breathable, less protective |

Understanding the Difference: Hard Hat vs Bump Cap

Hard hats provide robust protection against high-impact collisions, falling objects, and electrical hazards, making them essential for construction and industrial sites. Bump caps offer lightweight protection designed to shield against minor bumps and scrapes in low-risk environments, such as maintenance or warehousing. Choosing between a hard hat and a bump cap requires assessing the specific workplace hazards and regulatory safety standards to ensure optimal head protection.

Key Features of Hard Hats

Hard hats feature a rigid outer shell made from high-density polyethylene or fiberglass, providing robust protection against impact and penetration hazards. They include a suspension system that absorbs shock, ensuring a secure and comfortable fit while reducing head injury risks. Hard hats often come with optional accessories such as face shields, earmuffs, and chin straps to enhance safety in various industrial environments.

Essential Qualities of Bump Caps

Bump caps provide lightweight head protection designed to guard against minor bumps and scrapes in low-risk environments, featuring a padded inner lining and a reinforced shell. Unlike hard hats, bump caps do not offer impact resistance against falling objects but excel in comfort and ventilation for extended wear. Their essential qualities include a snug fit, absorbent sweatbands, and compliance with safety standards such as EN 812 for effective protection in confined or low-clearance workspaces.

Primary Applications: When to Use Hard Hats

Hard hats are essential for construction sites, industrial environments, and areas with high-risk falling objects, offering full impact protection and electrical insulation. Unlike bump caps, which are designed for low-risk situations with minor head bumps, hard hats provide robust defense against heavy impacts, penetration hazards, and arc flashes. Use hard hats in mining, manufacturing plants, and utility work where strict safety regulations demand certified head protection.

Ideal Use Cases for Bump Caps

Bump caps are ideal for environments with low-impact hazards such as confined spaces, indoor maintenance, and light industrial tasks where protection against minor bumps and scrapes is sufficient. Unlike hard hats, bump caps are lightweight and provide comfort during extended wear, making them suitable for electricians, plumbers, and warehouse workers. They offer a practical solution for reducing head injuries in situations where falling objects are unlikely but accidental head contact with fixed structures is common.

Safety Standards and Certifications

Hard hats must comply with ANSI/ISEA Z89.1 or EN 397 standards, ensuring impact resistance and electrical insulation for high-risk environments. Bump caps meet lower safety criteria, typically adhering to EN 812, designed for protection against minor bumps rather than heavy impacts. Choosing the correct headgear based on these certifications is crucial to meet workplace safety regulations and prevent head injuries effectively.

Comfort and Ergonomics Comparison

Hard hats provide superior impact protection but tend to be heavier and less ventilated, affecting comfort during extended wear. Bump caps offer lighter weight and increased breathability, enhancing ergonomic comfort for mild hazard environments but at the cost of reduced impact resistance. Choosing between hard hats and bump caps depends on balancing safety requirements with wearer comfort and ergonomic needs.

Durability and Material Strength

Hard hats are constructed with high-density polyethylene (HDPE) or fiberglass, offering superior durability and impact resistance for heavy-duty industrial environments. Bump caps utilize lighter materials such as thermoplastic or soft foam, providing limited protection primarily against minor bumps and scrapes. The material strength of hard hats meets stringent safety standards like ANSI/ISEA Z89.1, whereas bump caps do not provide the same certified level of protection, making hard hats the preferred choice for hazardous conditions.

Cost Considerations: Hard Hat vs Bump Cap

Hard hats typically cost more than bump caps due to their enhanced impact resistance, certifications, and materials designed for higher safety standards. Bump caps offer a budget-friendly alternative for low-risk environments, providing protection against minor head bumps rather than heavy impacts. Choosing between the two often depends on workplace hazards and budget constraints, with hard hats favored for industrial sites and bump caps suited for light-duty tasks.

Choosing the Right Head Protection for Your Workplace

Selecting the appropriate head protection for your workplace requires understanding the differences between hard hats and bump caps. Hard hats provide impact resistance against falling objects and electrical hazards, making them essential in construction, manufacturing, and industrial environments. Bump caps offer lightweight protection against minor bumps and scrapes, ideal for low-risk settings like warehousing or maintenance tasks without overhead hazards.

Hard hat vs Bump cap Infographic

productdif.com

productdif.com