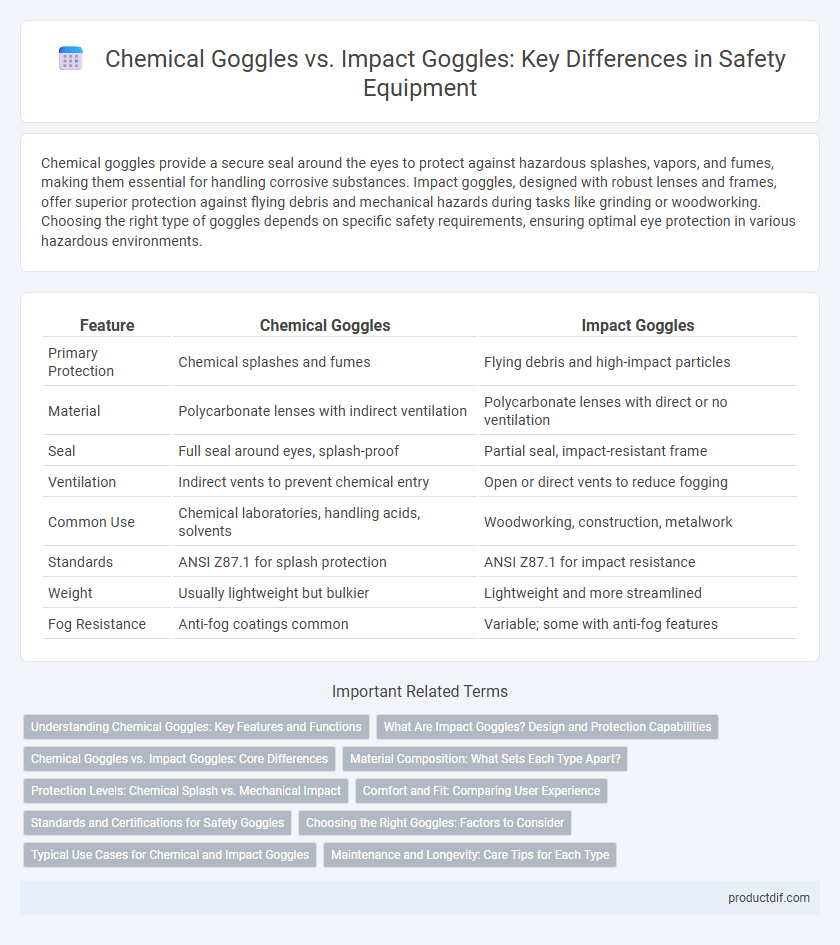

Chemical goggles provide a secure seal around the eyes to protect against hazardous splashes, vapors, and fumes, making them essential for handling corrosive substances. Impact goggles, designed with robust lenses and frames, offer superior protection against flying debris and mechanical hazards during tasks like grinding or woodworking. Choosing the right type of goggles depends on specific safety requirements, ensuring optimal eye protection in various hazardous environments.

Table of Comparison

| Feature | Chemical Goggles | Impact Goggles |

|---|---|---|

| Primary Protection | Chemical splashes and fumes | Flying debris and high-impact particles |

| Material | Polycarbonate lenses with indirect ventilation | Polycarbonate lenses with direct or no ventilation |

| Seal | Full seal around eyes, splash-proof | Partial seal, impact-resistant frame |

| Ventilation | Indirect vents to prevent chemical entry | Open or direct vents to reduce fogging |

| Common Use | Chemical laboratories, handling acids, solvents | Woodworking, construction, metalwork |

| Standards | ANSI Z87.1 for splash protection | ANSI Z87.1 for impact resistance |

| Weight | Usually lightweight but bulkier | Lightweight and more streamlined |

| Fog Resistance | Anti-fog coatings common | Variable; some with anti-fog features |

Understanding Chemical Goggles: Key Features and Functions

Chemical goggles provide a secure seal around the eyes to protect against hazardous splashes, vapors, and airborne particles commonly encountered in laboratories and industrial settings. Their indirect ventilation system prevents liquid entry while allowing airflow to reduce fogging, ensuring clear vision during chemical handling. Impact goggles, by contrast, prioritize protection from flying debris and physical impacts but lack the sealed design necessary to guard against chemical exposure effectively.

What Are Impact Goggles? Design and Protection Capabilities

Impact goggles feature a robust design with polycarbonate lenses and reinforced frames, engineered to protect against high-velocity debris and flying particles. They incorporate side shields and a secure strap to ensure a snug fit, minimizing the risk of injury during heavy-duty tasks. Unlike chemical goggles, impact goggles prioritize resistance to mechanical impact over chemical splash protection.

Chemical Goggles vs. Impact Goggles: Core Differences

Chemical goggles provide a sealed barrier protecting against liquid splashes, vapors, and harmful chemical fumes, making them essential in laboratories and industrial settings handling hazardous substances. Impact goggles are designed with durable, shatter-resistant materials to shield the eyes from flying debris, particles, and mechanical impacts in construction, manufacturing, and sports environments. Understanding these core differences ensures proper eye protection tailored to specific workplace hazards, reducing the risk of injury and maintaining safety compliance.

Material Composition: What Sets Each Type Apart?

Chemical goggles are typically made from flexible PVC or rubber frames with polycarbonate lenses, providing a tight seal and resistance to chemical splashes and vapors. Impact goggles feature rigid frames constructed from durable plastics and polycarbonate lenses designed to withstand high-velocity impacts and debris. The key difference lies in the chemical goggles' sealing materials for splash protection versus the impact goggles' robust construction for physical hazard defense.

Protection Levels: Chemical Splash vs. Mechanical Impact

Chemical goggles provide a sealed barrier that protects eyes from hazardous chemical splashes, vapors, and fumes, ensuring comprehensive coverage and preventing liquid penetration. Impact goggles are designed to withstand high-velocity impacts and flying debris, offering robust mechanical protection with reinforced lenses and durable frame materials. Selecting the appropriate goggles depends on whether the primary hazard involves chemical exposure or physical impacts, as each type optimizes protection for different safety risks.

Comfort and Fit: Comparing User Experience

Chemical goggles provide a secure seal around the eyes, ensuring protection against liquid splashes but often feeling tighter and less breathable, which can affect overall comfort during extended use. Impact goggles typically offer a more ventilated design with adjustable straps, enhancing breathability and fit flexibility for prolonged wear without excessive pressure. User experience favors impact goggles for comfort due to their lightweight construction and ergonomic design, while chemical goggles prioritize safety with a snug fit that may compromise comfort.

Standards and Certifications for Safety Goggles

Chemical goggles must meet ANSI Z87.1 standards for splash and chemical resistance, ensuring protection against hazardous liquids and vapors. Impact goggles also adhere to ANSI Z87.1 but emphasize high-velocity impact resistance, with certifications indicating compliance to specific impact testing criteria. Both types often carry dual markings indicating compliance with OSHA and CSA standards for workplace safety.

Choosing the Right Goggles: Factors to Consider

Choosing the right safety goggles depends on the specific hazards present, such as chemical splashes or flying debris. Chemical goggles offer a sealed design to protect against liquid exposure, while impact goggles provide robust resistance against high-velocity particles. Consider factors like lens material, ventilation type, and compliance with standards such as ANSI Z87.1 to ensure optimal protection.

Typical Use Cases for Chemical and Impact Goggles

Chemical goggles are primarily used in laboratory and industrial settings where protection against hazardous liquid splashes, fumes, and vapors is essential, such as handling acids, solvents, or disinfectants. Impact goggles are designed for high-velocity particle protection in environments like construction sites, woodworking shops, and manufacturing plants, where flying debris or dust poses a risk. Both types of goggles comply with ANSI Z87.1 standards, but chemical goggles emphasize seal and chemical resistance, while impact goggles focus on impact durability and ventilation.

Maintenance and Longevity: Care Tips for Each Type

Chemical goggles require regular cleaning with mild soap and water to prevent chemical residue buildup that can degrade lens clarity and material integrity, ensuring prolonged protection against hazardous substances. Impact goggles demand inspection for scratches or cracks and replacement of worn straps to maintain secure fit and optimal impact resistance over time. Proper storage in a dry, cool place away from direct sunlight extends the lifespan of both types by preventing material degradation and preserving their safety performance.

chemical goggles vs impact goggles Infographic

productdif.com

productdif.com