Type I safety helmets provide protection primarily from impacts to the top of the head, making them suitable for general construction and industrial environments. Type II safety helmets offer enhanced lateral protection, guarding against side and front impacts, which is crucial for tasks involving potential falling objects or angled strikes. Choosing the correct type ensures optimal safety and compliance with workplace standards.

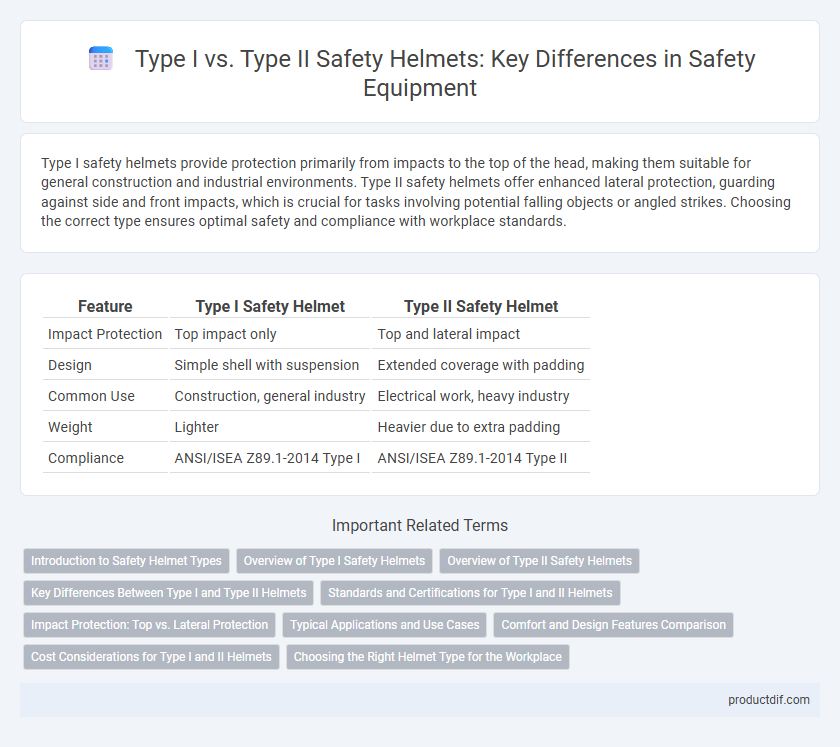

Table of Comparison

| Feature | Type I Safety Helmet | Type II Safety Helmet |

|---|---|---|

| Impact Protection | Top impact only | Top and lateral impact |

| Design | Simple shell with suspension | Extended coverage with padding |

| Common Use | Construction, general industry | Electrical work, heavy industry |

| Weight | Lighter | Heavier due to extra padding |

| Compliance | ANSI/ISEA Z89.1-2014 Type I | ANSI/ISEA Z89.1-2014 Type II |

Introduction to Safety Helmet Types

Type I safety helmets are designed to provide protection primarily against impact from the top of the head, making them suitable for environments where falling objects are the main hazard. Type II safety helmets offer enhanced protection by safeguarding against lateral impacts, protecting the sides as well as the crown of the head, which is crucial in workplaces with a higher risk of side impacts or falling debris. Both helmet types comply with ANSI/ISEA Z89.1 standards, ensuring reliable safety performance based on the specific requirements of industrial and construction settings.

Overview of Type I Safety Helmets

Type I safety helmets are designed primarily to provide protection from impacts to the top of the head, commonly used in construction and industrial environments. They feature a rigid outer shell combined with internal suspension systems to absorb shock and reduce the risk of injury from falling objects. These helmets meet ANSI/ISEA Z89.1 Type I standards, ensuring reliable performance in vertical impact scenarios.

Overview of Type II Safety Helmets

Type II safety helmets provide enhanced lateral protection compared to Type I helmets, covering the sides and back of the head to reduce the risk of injury from angled impacts. These helmets are commonly used in construction, industrial, and utility work environments where side impacts are more frequent. Designed to meet ANSI/ISEA Z89.1 standards, Type II helmets feature improved suspension systems and cushioning for better shock absorption and wearer comfort.

Key Differences Between Type I and Type II Helmets

Type I safety helmets provide protection primarily from impacts to the top of the head, making them suitable for general construction and industrial environments. Type II helmets offer enhanced protection by guarding against lateral impacts to the sides and back of the head, often featuring extended brims and additional internal padding. The key differences between Type I and Type II helmets lie in their impact resistance zones and design standards as defined by OSHA and ANSI/ISEA Z89.1.

Standards and Certifications for Type I and II Helmets

Type I safety helmets meet OSHA and ANSI Z89.1 standards, providing impact protection primarily to the top of the head, while Type II helmets comply with the same standards but offer enhanced lateral impact protection. ANSI Z89.1 categorizes Type I helmets for vertical impacts and Type II for both vertical and lateral impacts, reflecting their certification differences. Compliance with these standards ensures that each helmet type is tested for specific impact zones, critical for workplace safety regulations.

Impact Protection: Top vs. Lateral Protection

Type I safety helmets primarily provide impact protection on the top of the head, designed to absorb vertical blows from falling objects common in construction and industrial environments. Type II safety helmets offer enhanced lateral protection to the sides and back of the head, reducing risks associated with side impacts and angled blows. Selecting the appropriate helmet type depends on the specific hazards present and the nature of potential impacts at the worksite.

Typical Applications and Use Cases

Type I safety helmets are primarily designed for top impact protection, making them ideal for construction sites, industrial work, and environments with falling objects hazards. Type II safety helmets provide enhanced lateral impact protection, suited for electricians, utility workers, and situations involving side impacts or electrical dangers. Choosing the correct helmet type depends on the specific risk profile, ensuring optimal head safety compliance with OSHA and ANSI standards.

Comfort and Design Features Comparison

Type I safety helmets provide protection primarily from impacts to the top of the head, featuring a simple, rounded design that often allows for better ventilation and lighter weight, enhancing overall comfort during extended wear. Type II helmets are designed with additional protection for the sides and back of the head, incorporating more complex suspension systems and padding that can increase weight but improve safety in lateral impacts. Design features such as adjustable straps, interior padding materials, and ventilation channels differ between the two types, with Type I favoring simplicity and breathability, while Type II emphasizes comprehensive coverage and impact resistance.

Cost Considerations for Type I and II Helmets

Type I safety helmets typically cost less due to their simpler design focused on top impact protection, making them a budget-friendly option for environments with lower risk of lateral impacts. In contrast, Type II helmets incorporate additional side impact protection, resulting in higher manufacturing costs and a greater price point, but offer enhanced safety for jobs involving risks from multiple directions. Investing in Type II helmets is justified in workplaces where the added lateral protection reduces injury risk and potential liability.

Choosing the Right Helmet Type for the Workplace

Type I safety helmets provide protection primarily against impacts to the top of the head, making them ideal for industries such as construction and manufacturing where falling objects are a common hazard. Type II safety helmets offer additional protection to the sides and back of the head, suited for environments with risks of lateral impacts, such as utility work and tree trimming. Selecting the right helmet type depends on the specific workplace hazards and compliance with OSHA standards to ensure maximum head protection.

Type I safety helmet vs Type II safety helmet Infographic

productdif.com

productdif.com