Cut-resistant gloves provide superior protection against sharp objects and are ideal for handling pet grooming tools or cleaning tasks that involve potential cuts. Disposable gloves offer convenience and hygiene by preventing contamination but lack durability and cut resistance, making them unsuitable for heavy-duty tasks. Choosing the right gloves depends on balancing the need for safety, comfort, and specific pet care activities.

Table of Comparison

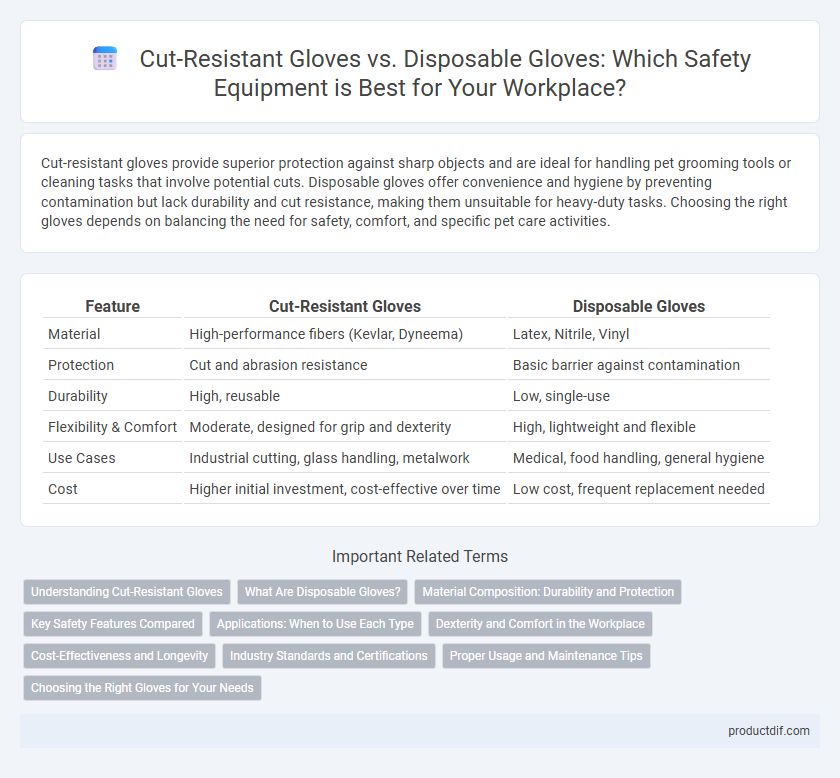

| Feature | Cut-Resistant Gloves | Disposable Gloves |

|---|---|---|

| Material | High-performance fibers (Kevlar, Dyneema) | Latex, Nitrile, Vinyl |

| Protection | Cut and abrasion resistance | Basic barrier against contamination |

| Durability | High, reusable | Low, single-use |

| Flexibility & Comfort | Moderate, designed for grip and dexterity | High, lightweight and flexible |

| Use Cases | Industrial cutting, glass handling, metalwork | Medical, food handling, general hygiene |

| Cost | Higher initial investment, cost-effective over time | Low cost, frequent replacement needed |

Understanding Cut-Resistant Gloves

Cut-resistant gloves are engineered with high-performance fibers such as Kevlar, Dyneema, or steel mesh to provide superior protection against sharp objects and abrasions, making them ideal for industries involving glass handling, metal fabrication, and construction. Unlike disposable gloves primarily made from latex, nitrile, or vinyl, which offer limited resistance to cuts and protect mainly against contamination and chemicals, cut-resistant gloves ensure enhanced durability and safety in hazardous environments. Their design prioritizes strength and flexibility, allowing workers to maintain dexterity while reducing the risk of hand injuries significantly.

What Are Disposable Gloves?

Disposable gloves are single-use protective hand coverings made from materials such as latex, nitrile, or vinyl, designed to provide a barrier against contaminants, chemicals, and pathogens. Commonly used in medical, food handling, and cleaning environments, they offer lightweight protection and prevent cross-contamination. Unlike cut-resistant gloves, disposable gloves prioritize hygiene and chemical resistance over mechanical protection.

Material Composition: Durability and Protection

Cut-resistant gloves are typically made from high-performance materials such as Kevlar, Dyneema, or stainless steel fibers, offering superior durability and protection against sharp objects and abrasions. In contrast, disposable gloves are usually composed of latex, nitrile, or vinyl, providing basic barrier protection against contaminants but limited resistance to cuts. The choice between these gloves depends on the need for mechanical strength and prolonged use versus short-term protection and hygiene.

Key Safety Features Compared

Cut-resistant gloves provide superior protection through high-performance fibers such as Kevlar, Dyneema, or stainless steel mesh that resist sharp objects and cuts, making them ideal for handling knives or glass. Disposable gloves, typically made from latex, nitrile, or vinyl, offer a barrier against contaminants and chemicals but lack durability and cut resistance. The choice between these gloves depends on the specific safety requirements, with cut-resistant gloves prioritizing physical protection while disposable gloves emphasize hygiene and chemical resistance.

Applications: When to Use Each Type

Cut-resistant gloves are essential in industries involving sharp tools or materials, such as construction, metalworking, and glass handling, providing protection against cuts and lacerations. Disposable gloves are ideal for tasks requiring hygiene and contamination control, including medical examinations, food handling, and laboratory work. Selecting the appropriate glove type depends on the balance between protection from physical hazards and preventing contamination.

Dexterity and Comfort in the Workplace

Cut-resistant gloves offer superior protection without compromising dexterity, allowing precise hand movements essential for tasks involving sharp objects, while disposable gloves prioritize lightweight comfort and flexibility but provide limited cut resistance. Workers requiring prolonged glove use benefit from cut-resistant gloves designed with breathable materials that reduce hand fatigue and enhance comfort. Disposable gloves excel in environments demanding frequent glove changes and high sensitivity, although they may cause hand sweating and reduced comfort over extended periods.

Cost-Effectiveness and Longevity

Cut-resistant gloves offer superior durability and long-term protection in hazardous environments, making them a cost-effective investment despite higher initial expenses. Disposable gloves, while inexpensive and ideal for single-use tasks, require frequent replacement, increasing overall costs over time. Evaluating workplace needs and glove lifespan helps determine the most economical choice for safety and budget efficiency.

Industry Standards and Certifications

Cut-resistant gloves must comply with industry standards such as ANSI/ISEA 105 and EN 388, which certify their ability to withstand cuts and abrasions in high-risk environments. Disposable gloves typically meet FDA and ASTM standards, ensuring chemical resistance, hygiene, and medical safety for short-term use. Selecting gloves with proper certifications guarantees compliance with safety regulations and optimal protection for specific industrial applications.

Proper Usage and Maintenance Tips

Cut-resistant gloves are designed for repetitive tasks involving sharp objects and should be regularly inspected for damage to maintain their protective qualities, while disposable gloves offer short-term protection against contaminants and must be discarded after each use to prevent cross-contamination. Proper usage of cut-resistant gloves includes selecting the appropriate cut resistance level based on task requirements and avoiding exposure to chemicals that may degrade the material. For disposable gloves, ensure proper fit and hand hygiene before and after use to maximize effectiveness and prevent skin irritation.

Choosing the Right Gloves for Your Needs

Cut-resistant gloves provide superior protection against sharp objects and are essential in industries like construction, manufacturing, and glass handling where risk of cuts is high. Disposable gloves, often made from latex, nitrile, or vinyl, offer convenience and hygiene for single-use tasks such as medical exams, food preparation, or chemical handling. Choosing the right gloves depends on assessing the level of protection needed, task duration, and exposure to contaminants or hazardous materials.

Cut-resistant Gloves vs Disposable Gloves Infographic

productdif.com

productdif.com