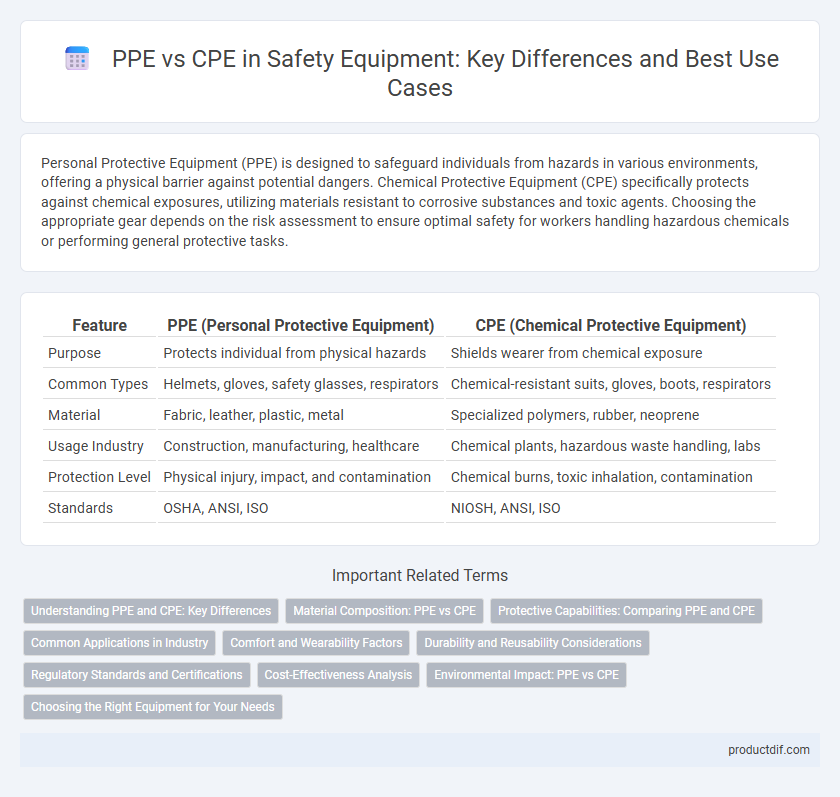

Personal Protective Equipment (PPE) is designed to safeguard individuals from hazards in various environments, offering a physical barrier against potential dangers. Chemical Protective Equipment (CPE) specifically protects against chemical exposures, utilizing materials resistant to corrosive substances and toxic agents. Choosing the appropriate gear depends on the risk assessment to ensure optimal safety for workers handling hazardous chemicals or performing general protective tasks.

Table of Comparison

| Feature | PPE (Personal Protective Equipment) | CPE (Chemical Protective Equipment) |

|---|---|---|

| Purpose | Protects individual from physical hazards | Shields wearer from chemical exposure |

| Common Types | Helmets, gloves, safety glasses, respirators | Chemical-resistant suits, gloves, boots, respirators |

| Material | Fabric, leather, plastic, metal | Specialized polymers, rubber, neoprene |

| Usage Industry | Construction, manufacturing, healthcare | Chemical plants, hazardous waste handling, labs |

| Protection Level | Physical injury, impact, and contamination | Chemical burns, toxic inhalation, contamination |

| Standards | OSHA, ANSI, ISO | NIOSH, ANSI, ISO |

Understanding PPE and CPE: Key Differences

Personal Protective Equipment (PPE) includes items like gloves, helmets, masks, and goggles designed to protect individuals from workplace hazards. Chemical Protective Equipment (CPE) is a specialized subset of PPE specifically engineered to shield users from chemical exposure, often featuring materials resistant to corrosive substances and toxic vapors. Understanding the distinctions in materials, intended applications, and compliance standards is crucial for selecting the appropriate safety gear to ensure effective protection in hazardous environments.

Material Composition: PPE vs CPE

Personal Protective Equipment (PPE) is typically made from materials like high-density polyethylene, nylon, and Kevlar, designed to provide impact resistance and durability. Chemical Protective Equipment (CPE), on the other hand, uses materials such as neoprene, nitrile, and PVC, which offer superior chemical resistance and impermeability. The selection between PPE and CPE is crucial depending on the hazard, with PPE optimized for physical threats and CPE targeting chemical exposure.

Protective Capabilities: Comparing PPE and CPE

Personal Protective Equipment (PPE) such as gloves, masks, and goggles offers individual-level protection against chemicals, biological agents, and physical hazards by creating a barrier on the body. Chemical Protective Equipment (CPE) is specifically designed to shield workers from chemical exposure through specialized materials and impermeable barriers, often providing enhanced resistance to toxins, acids, and solvents. Comparing protective capabilities, CPE generally delivers higher resistance to hazardous chemicals, whereas PPE offers broader protection for various workplace risks but may vary in effectiveness depending on the material and application.

Common Applications in Industry

Personal Protective Equipment (PPE) is widely used in industries such as construction, manufacturing, and healthcare to protect workers from physical hazards, chemical exposure, and biological risks. Chemical Protective Equipment (CPE) is specifically designed for industries like chemical processing, pharmaceuticals, and laboratories where exposure to hazardous substances requires specialized protection. Both PPE and CPE are essential for ensuring workplace safety, but CPE offers enhanced resistance to corrosive chemicals and toxic materials, making it crucial for high-risk chemical environments.

Comfort and Wearability Factors

Personal Protective Equipment (PPE) and Chemical Protective Equipment (CPE) differ significantly in comfort and wearability, with PPE generally designed for broader use and greater breathability. CPE, while offering enhanced chemical resistance, often sacrifices comfort due to its bulkier materials and reduced ventilation. Selecting appropriate safety gear necessitates balancing protective performance with ergonomic design to ensure sustained wearability during extended work periods.

Durability and Reusability Considerations

Personal Protective Equipment (PPE) and Controlled Protective Equipment (CPE) differ significantly in durability and reusability, with PPE often designed for single-use or limited reuse, focusing on disposable materials to prevent contamination. CPE generally features robust construction from durable materials like reinforced fabrics or heavy-duty polymers, allowing multiple uses and extended service life without compromising safety standards. Selecting between PPE and CPE requires evaluating the frequency of use, exposure risks, and cost-effectiveness linked to maintenance, cleaning protocols, and product lifespan.

Regulatory Standards and Certifications

Personal Protective Equipment (PPE) must comply with regulatory standards such as OSHA in the United States and EN ISO standards in Europe, ensuring certified protection against workplace hazards. Chemical Protective Equipment (CPE) adheres to more specific certifications like NFPA 1991 and EN 943, which certify resistance to hazardous chemicals and provide performance benchmarks for material durability. Compliance with these certification standards guarantees worker safety by validating the effectiveness and reliability of PPE and CPE in various industrial environments.

Cost-Effectiveness Analysis

Personal Protective Equipment (PPE) and Collective Protective Equipment (CPE) both play critical roles in workplace safety, but cost-effectiveness analysis often favors CPE due to its ability to protect multiple workers simultaneously, reducing per-person costs over time. While PPE requires individual investment and frequent replacement, CPE typically involves higher initial expenditure but lower long-term operational costs and maintenance. Evaluating total lifecycle costs alongside risk reduction efficiency is essential for organizations aiming to optimize safety budgets without compromising protection.

Environmental Impact: PPE vs CPE

Personal Protective Equipment (PPE) typically includes disposable items such as masks, gloves, and gowns that generate considerable waste contributing to environmental pollution, whereas Chemical Protective Equipment (CPE) often involves reusable suits and gear designed for hazardous environments, reducing single-use waste. PPE disposal methods can lead to microplastic contamination and landfill accumulation, while CPE materials are often engineered for durability and can be cleaned and reused, minimizing environmental footprint. Lifecycle assessment studies show that investing in CPE with proper maintenance significantly lowers carbon emissions and resource depletion compared to the frequent replacement cycle of PPE.

Choosing the Right Equipment for Your Needs

Personal Protective Equipment (PPE) encompasses gear designed to protect against workplace hazards, including helmets, gloves, and masks, while Chemical Protective Equipment (CPE) specifically guards against chemical exposures with materials resistant to corrosive substances. Selecting the right equipment depends on hazard assessment, exposure type, and industry standards such as OSHA or ANSI to ensure maximum safety and compliance. Proper fit, material compatibility, and intended use are critical factors to optimize protection and performance in safety gear selection.

PPE vs CPE Infographic

productdif.com

productdif.com