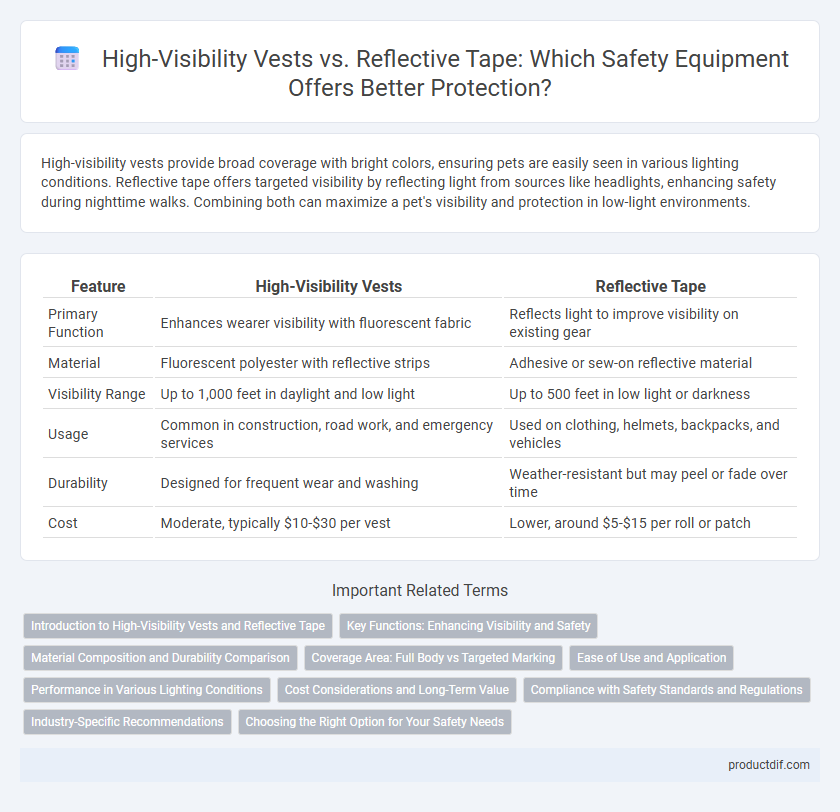

High-visibility vests provide broad coverage with bright colors, ensuring pets are easily seen in various lighting conditions. Reflective tape offers targeted visibility by reflecting light from sources like headlights, enhancing safety during nighttime walks. Combining both can maximize a pet's visibility and protection in low-light environments.

Table of Comparison

| Feature | High-Visibility Vests | Reflective Tape |

|---|---|---|

| Primary Function | Enhances wearer visibility with fluorescent fabric | Reflects light to improve visibility on existing gear |

| Material | Fluorescent polyester with reflective strips | Adhesive or sew-on reflective material |

| Visibility Range | Up to 1,000 feet in daylight and low light | Up to 500 feet in low light or darkness |

| Usage | Common in construction, road work, and emergency services | Used on clothing, helmets, backpacks, and vehicles |

| Durability | Designed for frequent wear and washing | Weather-resistant but may peel or fade over time |

| Cost | Moderate, typically $10-$30 per vest | Lower, around $5-$15 per roll or patch |

Introduction to High-Visibility Vests and Reflective Tape

High-visibility vests are designed with fluorescent materials that enhance daytime visibility, making them essential for workers in construction, traffic control, and emergency response. Reflective tape, composed of retroreflective materials, improves visibility by reflecting light in low-light or nighttime conditions, often applied on clothing or equipment. Both safety solutions are critical for preventing accidents by increasing the wearer's visual presence in various environments.

Key Functions: Enhancing Visibility and Safety

High-visibility vests use fluorescent colors like neon yellow and orange to enhance daytime visibility, making wearers easily noticeable in various lighting conditions. Reflective tape relies on retroreflective materials that bounce light back to its source, significantly increasing visibility in low-light or nighttime environments. Combining high-visibility vests with strategically placed reflective tape maximizes safety by ensuring consistent visibility across all times of day and weather conditions.

Material Composition and Durability Comparison

High-visibility vests are typically made from lightweight polyester mesh embedded with fluorescent dyes, ensuring high visibility during daylight, while reflective tape consists of microprismatic or glass bead technology designed to reflect light in low-light conditions. Polyester vest materials are often enhanced with UV-resistant treatments for durability, yet they can degrade under prolonged exposure to harsh weather. Reflective tape offers superior longevity on various surfaces due to its adhesive backing and abrasion-resistant properties, maintaining reflectivity after repeated washing and environmental wear.

Coverage Area: Full Body vs Targeted Marking

High-visibility vests provide full-body coverage, enhancing overall visibility for workers in hazardous environments by using bright colors and reflective materials across a large surface area. Reflective tape offers targeted marking, focusing on specific parts of clothing or equipment to increase visibility in low-light conditions without full-body coverage. Choosing between the two depends on the level of visibility needed and the work environment, with vests being more comprehensive and reflective tape offering flexible, localized enhancement.

Ease of Use and Application

High-visibility vests offer immediate, full-body visibility with straightforward wearability, making them highly practical for workers in dynamic environments. Reflective tape requires precise application on clothing or gear, demanding time and careful positioning to ensure optimal reflectivity. The vest's one-piece design simplifies use, while reflective tape provides customizable placement but involves more effort in application and maintenance.

Performance in Various Lighting Conditions

High-visibility vests provide consistent visibility across diverse lighting conditions due to their fluorescent materials that enhance daytime recognition. Reflective tape excels in low-light and nighttime environments by reflecting light from sources such as headlights, significantly improving wearer visibility. Combining both high-visibility vests with reflective tape delivers optimal performance by ensuring visibility in both daylight and darkness.

Cost Considerations and Long-Term Value

High-visibility vests typically involve a higher initial cost but provide durable, all-over visibility that reduces replacement frequency, offering long-term value in safety compliance. Reflective tape is a more affordable option upfront, suitable for enhancing visibility on existing garments, but may require frequent reapplication or replacement due to wear and environmental exposure. Evaluating total lifecycle expenses, including maintenance and replacement frequency, is crucial for choosing between these safety equipment options based on budget and operational needs.

Compliance with Safety Standards and Regulations

High-visibility vests meet regulatory requirements such as ANSI/ISEA 107 and EN ISO 20471, ensuring workers are easily seen in various environments. Reflective tape enhances visibility by providing additional reflective surfaces but often does not fully comply with standalone safety standards. Combining high-visibility vests with certified reflective tape ensures maximum compliance with occupational health and safety regulations.

Industry-Specific Recommendations

High-visibility vests provide comprehensive visibility with fluorescent colors and integrated reflective strips, making them ideal for construction workers exposed to both daylight and low-light conditions. Reflective tape enhances existing clothing or equipment, offering flexibility for industries like logistics or warehouse operations where full vests may hinder mobility. Industry standards such as ANSI/ISEA 107 for high-visibility apparel guide the selection based on risk levels and working environments to optimize worker safety.

Choosing the Right Option for Your Safety Needs

High-visibility vests provide comprehensive coverage with bright fluorescent colors that enhance visibility during the day, making them ideal for environments with constant movement and daylight conditions. Reflective tape excels in low-light or nighttime settings by reflecting light back to its source, making it an excellent supplement for existing clothing or gear. Selecting the right safety equipment depends on the specific work environment, lighting conditions, and the level of visibility required to maximize protection.

High-visibility vests vs Reflective tape Infographic

productdif.com

productdif.com