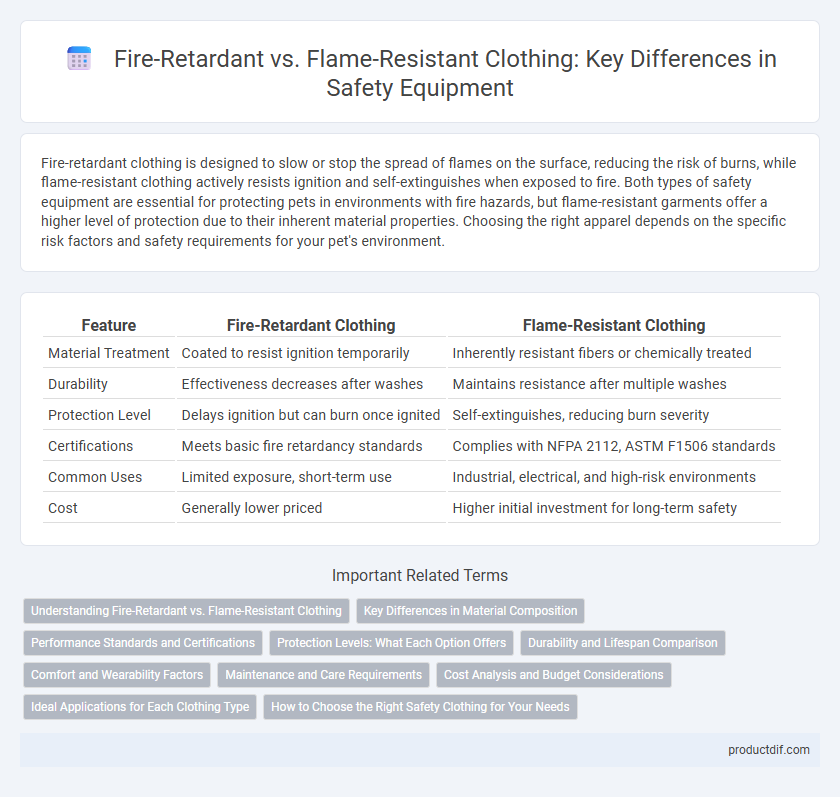

Fire-retardant clothing is designed to slow or stop the spread of flames on the surface, reducing the risk of burns, while flame-resistant clothing actively resists ignition and self-extinguishes when exposed to fire. Both types of safety equipment are essential for protecting pets in environments with fire hazards, but flame-resistant garments offer a higher level of protection due to their inherent material properties. Choosing the right apparel depends on the specific risk factors and safety requirements for your pet's environment.

Table of Comparison

| Feature | Fire-Retardant Clothing | Flame-Resistant Clothing |

|---|---|---|

| Material Treatment | Coated to resist ignition temporarily | Inherently resistant fibers or chemically treated |

| Durability | Effectiveness decreases after washes | Maintains resistance after multiple washes |

| Protection Level | Delays ignition but can burn once ignited | Self-extinguishes, reducing burn severity |

| Certifications | Meets basic fire retardancy standards | Complies with NFPA 2112, ASTM F1506 standards |

| Common Uses | Limited exposure, short-term use | Industrial, electrical, and high-risk environments |

| Cost | Generally lower priced | Higher initial investment for long-term safety |

Understanding Fire-Retardant vs. Flame-Resistant Clothing

Fire-retardant clothing is treated with chemical coatings that delay ignition and slow the spread of flames, providing temporary protection against fire hazards. Flame-resistant clothing, however, is made from inherently self-extinguishing fibers that resist ignition and continue to protect the wearer even after exposure to flame. Understanding the difference is crucial for selecting appropriate safety gear in environments with varying fire risks and compliance requirements.

Key Differences in Material Composition

Fire-retardant clothing is typically treated with chemical coatings that inhibit combustion and slow the spread of flames, while flame-resistant clothing is made from inherently resistant fibers like aramid, modacrylic, or treated cotton that self-extinguish when exposed to fire. The chemical treatment in fire-retardant garments may wear off over time or with laundering, whereas flame-resistant fabrics maintain their protective properties throughout the garment's lifespan. Understanding these material composition differences is critical for selecting appropriate safety equipment based on exposure risk and durability requirements.

Performance Standards and Certifications

Fire-retardant clothing must comply with NFPA 2112 or ASTM F1930 standards, ensuring garments self-extinguish within seconds after exposure to flames. Flame-resistant clothing meets rigorous criteria under standards like NFPA 70E and EN ISO 11612, guaranteeing durability against heat and arc flash hazards. Certifications such as UL, Oeko-Tex, and ISO 11611 verify materials' resistance performance and worker protection effectiveness.

Protection Levels: What Each Option Offers

Fire-retardant clothing provides a barrier that slows the ignition and spread of flames, reducing burn injuries by allowing time to escape fire hazards. Flame-resistant clothing offers intrinsic protection by self-extinguishing when the heat source is removed, ensuring longer exposure without catching fire. Both types are tested to regulatory standards like NFPA 2112 and ASTM F1506, but flame-resistant garments generally deliver higher protection levels for extreme fire exposure scenarios.

Durability and Lifespan Comparison

Fire-retardant clothing is treated with chemicals that can wash out over time, reducing its effectiveness and lifespan, typically requiring replacement after multiple wears or washes. Flame-resistant clothing is made from inherently resistant fibers such as Nomex or Kevlar, providing durable protection that lasts the garment's lifetime without degradation. This intrinsic strength ensures flame-resistant clothing delivers a longer, more reliable safety performance compared to fire-retardant alternatives.

Comfort and Wearability Factors

Fire-retardant clothing uses materials treated with chemicals to resist ignition, offering lightweight comfort and breathability, which enhances wearability during extended use. Flame-resistant clothing is made from inherently resistant fibers like aramid or modacrylic, providing durable protection but sometimes sacrificing flexibility and cooling properties. Prioritizing comfort, safety professionals select gear balancing thermal protection with moisture-wicking and ergonomic design for optimal user endurance on the job.

Maintenance and Care Requirements

Fire-retardant clothing typically requires specific washing procedures, such as using mild detergents and avoiding fabric softeners, to maintain its protective properties and prevent degradation of the fire-resistant treatment. Flame-resistant clothing, often made from inherently resistant fibers like aramid or modacrylic, retains its protective qualities through multiple washes but still demands regular inspection for wear, tears, or contamination that could compromise safety. Proper drying methods, such as air drying or low heat, are crucial for both types to preserve fabrics' integrity and performance over time.

Cost Analysis and Budget Considerations

Fire-retardant clothing generally costs less upfront but may require more frequent replacement due to reduced durability after multiple washes, impacting long-term budget considerations. Flame-resistant clothing often comes with a higher initial price due to advanced materials and certification standards but offers extended wear life and sustained protection, which can reduce overall lifecycle costs. Organizations should analyze total cost of ownership by weighing initial investment against maintenance frequency, employee safety needs, and regulatory compliance to optimize their safety equipment budget.

Ideal Applications for Each Clothing Type

Fire-retardant clothing is ideal for environments with potential exposure to open flames where temporary contact with fire or sparks may occur, such as welding or cutting operations. Flame-resistant clothing is best suited for industries with continuous or high-risk fire hazards, including oil and gas, electrical work, and chemical manufacturing, as it provides long-lasting protection by self-extinguishing flames. Choosing the appropriate type depends on the specific fire exposure risk and duration in the workplace to ensure optimal worker safety and compliance with regulatory standards.

How to Choose the Right Safety Clothing for Your Needs

Selecting the right safety clothing requires understanding the key differences between fire-retardant and flame-resistant materials. Fire-retardant clothing is treated to resist ignition and self-extinguish, ideal for environments with occasional fire exposure, while flame-resistant clothing is inherently resistant to flames and maintains protection even after multiple washes, suitable for sustained high-risk conditions. Evaluate your workplace hazards, exposure duration, and industry standards such as NFPA 2112 and OSHA regulations to ensure compliance and optimal protection.

Fire-retardant clothing vs Flame-resistant clothing Infographic

productdif.com

productdif.com