Impact gloves provide enhanced protection against blunt force trauma and vibrations, making them ideal for handling heavy tools or machinery. Cut-resistant gloves are engineered with materials like Kevlar or Dyneema to prevent injuries from sharp objects, offering superior defense against slicing hazards. Choosing the right safety equipment depends on the specific risks involved in the task to ensure maximum hand protection for pets during handling.

Table of Comparison

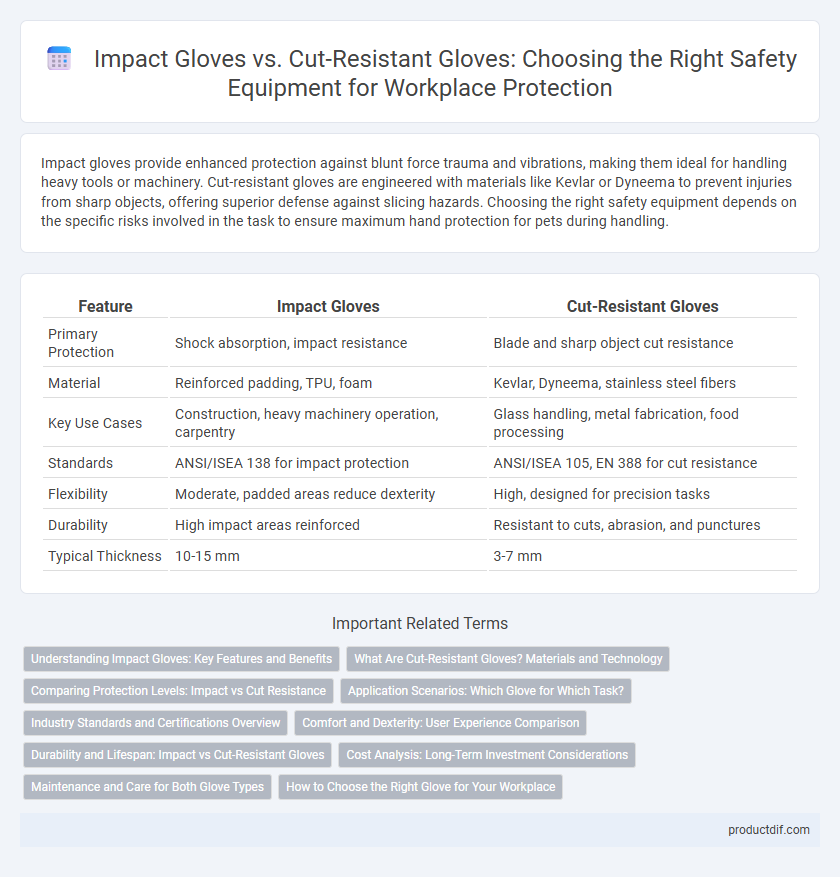

| Feature | Impact Gloves | Cut-Resistant Gloves |

|---|---|---|

| Primary Protection | Shock absorption, impact resistance | Blade and sharp object cut resistance |

| Material | Reinforced padding, TPU, foam | Kevlar, Dyneema, stainless steel fibers |

| Key Use Cases | Construction, heavy machinery operation, carpentry | Glass handling, metal fabrication, food processing |

| Standards | ANSI/ISEA 138 for impact protection | ANSI/ISEA 105, EN 388 for cut resistance |

| Flexibility | Moderate, padded areas reduce dexterity | High, designed for precision tasks |

| Durability | High impact areas reinforced | Resistant to cuts, abrasion, and punctures |

| Typical Thickness | 10-15 mm | 3-7 mm |

Understanding Impact Gloves: Key Features and Benefits

Impact gloves are designed with reinforced padding and shock-absorbing materials to protect hands from blunt force trauma during heavy-duty tasks. These gloves feature flexible knuckle guards, durable outer shells, and enhanced grip surfaces, providing safety without sacrificing dexterity. Commonly used in construction, automotive, and manufacturing industries, impact gloves reduce the risk of injuries from drops, strikes, and vibrations, improving overall hand protection.

What Are Cut-Resistant Gloves? Materials and Technology

Cut-resistant gloves are designed using high-performance materials such as Kevlar, Dyneema, and stainless steel fibers to provide robust protection against sharp objects and slashes. Advanced knitting technology and coatings like nitrile or polyurethane enhance grip and durability while maintaining flexibility for precise handling. These gloves are essential in industries like construction, metal fabrication, and glass handling where preventing lacerations is critical for worker safety.

Comparing Protection Levels: Impact vs Cut Resistance

Impact gloves are designed with reinforced padding and shock-absorbing materials to protect hands from blunt force trauma, making them ideal for tasks involving heavy machinery or potential strikes. Cut-resistant gloves are fabricated using high-performance fibers such as Kevlar or Dyneema to provide superior protection against sharp objects, preventing lacerations and punctures. When choosing between impact gloves and cut-resistant gloves, assessing the specific hazards of the task is crucial to ensure optimal hand protection tailored to blunt impact or sharp cutting risks.

Application Scenarios: Which Glove for Which Task?

Impact gloves are designed for high-impact tasks such as construction, heavy machinery operation, and demolition, providing maximum protection against abrasions, bruises, and blunt force trauma. Cut-resistant gloves are ideal for precision tasks involving sharp objects, such as glass handling, metal fabrication, and food processing, where preventing lacerations is critical. Selecting the right glove depends on task-specific hazards, with impact gloves suited for blunt force protection and cut-resistant gloves prioritized for sharp edge safety.

Industry Standards and Certifications Overview

Impact gloves and cut-resistant gloves adhere to distinct industry standards and certifications designed to ensure optimal protection. Impact gloves are commonly tested to ANSI/ISEA 138 standards, which evaluate impact resistance across palm, back-of-hand, and finger areas, while cut-resistant gloves are certified under standards such as EN 388 and ANSI/ISEA 105, focusing on cut, abrasion, and puncture resistance levels. Selecting gloves based on these specific certifications guarantees compliance with workplace safety regulations and maximizes hazard protection tailored to the risk environment.

Comfort and Dexterity: User Experience Comparison

Impact gloves are designed with flexible padding and breathable materials that enhance comfort and maintain dexterity during high-impact tasks. Cut-resistant gloves prioritize protection by using thicker, more rigid fibers such as Kevlar or Dyneema, which can reduce flexibility and tactile sensitivity. Users seeking a balance between protection and comfort often prefer impact gloves for prolonged wear, while cut-resistant gloves are favored in environments demanding superior sharp object defense despite a slight trade-off in dexterity.

Durability and Lifespan: Impact vs Cut-Resistant Gloves

Impact gloves are engineered with reinforced padding and shock-absorbing materials that provide long-lasting protection against blunt force, ensuring extended durability in high-impact environments. Cut-resistant gloves utilize high-performance fibers like Kevlar or Dyneema, offering superior resistance to blade penetration but may experience fiber degradation over time with heavy use. Both glove types maintain lifespan through material quality, yet impact gloves generally withstand repeated physical stress better, while cut-resistant gloves require careful inspection for wear to ensure ongoing protection.

Cost Analysis: Long-Term Investment Considerations

Impact gloves generally cost more upfront due to specialized padding and shock absorption materials designed to protect against blunt force trauma. Cut-resistant gloves often require more frequent replacement, as sharp-edge exposure can degrade fibers rapidly, leading to higher long-term expenses despite a lower initial price. Evaluating total cost of ownership involves balancing the durability and protection level of impact gloves against the periodic replacement costs of cut-resistant gloves in high-risk environments.

Maintenance and Care for Both Glove Types

Proper maintenance of impact gloves involves regularly inspecting for wear in padding and replacing gloves with compromised shock absorption to maintain protection. Cut-resistant gloves require careful cleaning with mild detergent and air drying to preserve fiber strength and ensure long-lasting cut resistance. Storing both glove types in a dry, cool environment away from chemicals extends their lifespan and maintains optimal performance on the job.

How to Choose the Right Glove for Your Workplace

Selecting the right glove for your workplace depends on the specific hazards present, whether the primary risk involves heavy impact or sharp objects. Impact gloves provide specialized padding and reinforcement to protect against blunt force trauma, making them ideal for construction and industrial environments where heavy tools or machinery are used. Cut-resistant gloves, made from materials like Kevlar or Dyneema, are essential in industries such as glass handling or metal fabrication, where sharp edges pose a significant injury risk, ensuring optimal safety and compliance.

Impact gloves vs Cut-resistant gloves Infographic

productdif.com

productdif.com