Class A gloves provide protection against low-heat exposures up to 500degF, making them ideal for handling hot objects in light industrial settings. Class B gloves are designed for high-heat environments, offering protection up to 1000degF and are often used in heavy-duty applications like foundries and metal forging. Choosing between Class A and Class B gloves depends on the specific temperature hazards and the level of heat resistance required to ensure pet safety during handling.

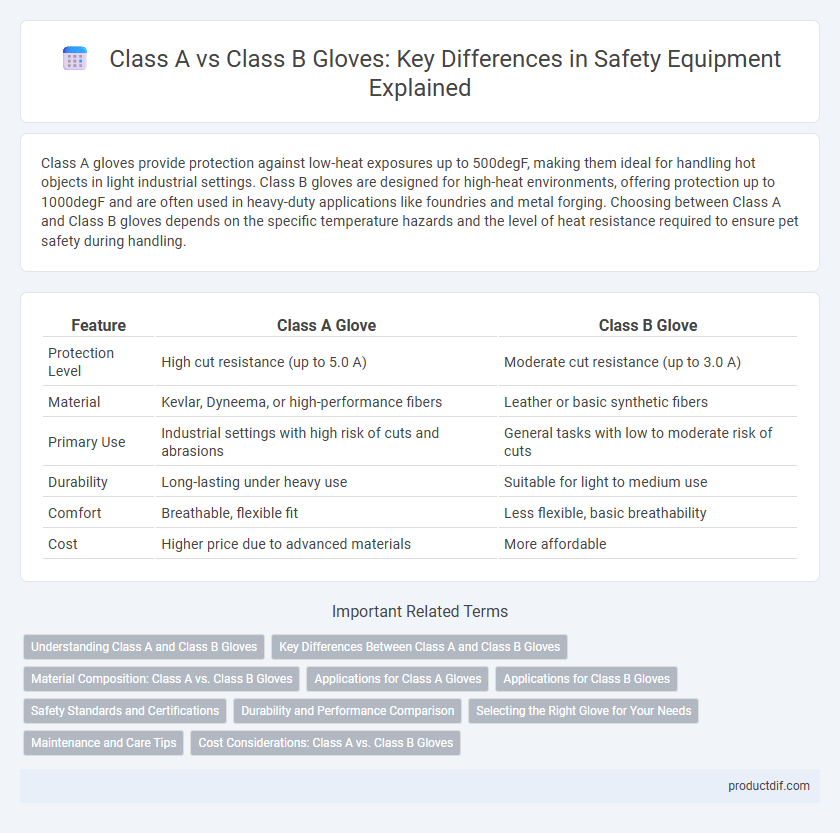

Table of Comparison

| Feature | Class A Glove | Class B Glove |

|---|---|---|

| Protection Level | High cut resistance (up to 5.0 A) | Moderate cut resistance (up to 3.0 A) |

| Material | Kevlar, Dyneema, or high-performance fibers | Leather or basic synthetic fibers |

| Primary Use | Industrial settings with high risk of cuts and abrasions | General tasks with low to moderate risk of cuts |

| Durability | Long-lasting under heavy use | Suitable for light to medium use |

| Comfort | Breathable, flexible fit | Less flexible, basic breathability |

| Cost | Higher price due to advanced materials | More affordable |

Understanding Class A and Class B Gloves

Class A gloves are designed to provide high levels of electrical insulation, typically rated for use up to 7,500 volts, making them suitable for tasks involving higher voltage exposure. Class B gloves offer enhanced protection, rated for electrical insulation up to 17,000 volts, ideal for professionals working with extremely high voltage systems. Selecting the correct glove class is essential for compliance with OSHA and ASTM standards to ensure optimal safety and prevent electrical injuries.

Key Differences Between Class A and Class B Gloves

Class A gloves offer protection against higher cut resistance with a rating of up to level 5, making them suitable for heavy-duty tasks involving sharp objects, while Class B gloves provide moderate cut resistance, typically rated at level 3. Class A gloves often feature thicker materials and reinforced palms for enhanced durability and impact resistance, whereas Class B gloves emphasize dexterity and flexibility for precision work. The primary distinctions lie in their material composition, cut protection level, and intended industrial applications, influencing the selection based on specific safety requirements.

Material Composition: Class A vs. Class B Gloves

Class A gloves are typically made from materials such as leather, Kevlar, or rubber, providing high resistance to cuts, heat, and abrasion, ideal for heavy-duty industrial tasks. In contrast, Class B gloves often use synthetic fibers like nylon or cotton blends, offering moderate protection suited for lighter mechanical work and reduced exposure to hazardous materials. The material composition directly influences durability, flexibility, and protection level, making selection critical for workplace safety compliance.

Applications for Class A Gloves

Class A gloves are designed for high heat resistance, making them ideal for handling hot metals, glass manufacturing, and foundry work where temperatures may reach up to 1000degF (537degC). These gloves provide superior protection against thermal hazards, ensuring safety in applications involving molten materials, welding, and furnace operations. Their insulating properties reduce the risk of burns, making them essential for heavy-duty industrial environments requiring prolonged heat exposure resistance.

Applications for Class B Gloves

Class B gloves are designed for high-voltage electrical work, offering protection against voltages up to 17,000 volts. These gloves are essential for electricians and utility workers handling live electrical circuits or performing maintenance on power lines. Their superior dielectric properties ensure safety in environments with elevated electrical hazards, making them suitable for industrial and commercial electrical applications.

Safety Standards and Certifications

Class A gloves comply with ANSI/ISEA 105 standards, providing protection against cut levels up to 2, ideal for light to moderate mechanical hazards. Class B gloves meet higher ANSI cut resistance ratings, typically level 3 or above, designed for heavy-duty applications requiring enhanced cutoff protection. Both classes often hold certifications such as EN 388, indicating compliance with European safety standards for abrasion, cut, tear, and puncture resistance.

Durability and Performance Comparison

Class A gloves offer superior durability with enhanced resistance to cuts, punctures, and abrasions, making them ideal for heavy-duty tasks requiring prolonged protection. In contrast, Class B gloves prioritize dexterity and tactile sensitivity but provide moderate durability suitable for lighter applications. Performance-wise, Class A gloves maintain structural integrity under extreme conditions, while Class B gloves deliver better precision, enhancing user control in detailed work.

Selecting the Right Glove for Your Needs

Class A gloves provide protection against high voltage up to 7,500 volts, making them suitable for low-voltage electrical work and general maintenance, while Class B gloves are rated for up to 17,000 volts, ideal for medium-voltage tasks and industrial applications. When selecting the right glove, consider the voltage exposure, durability requirements, and OSHA or ASTM standards compliance to ensure optimal safety. Proper inspection and regular testing according to regulatory guidelines prevent glove failure and enhance worker protection.

Maintenance and Care Tips

Class A gloves, designed for low voltage protection up to 7,500 volts, require regular inspection for cuts, punctures, and chemical damage to maintain their insulating properties. Class B gloves, rated for higher voltages up to 17,000 volts, demand more stringent care, including frequent dielectric testing and careful storage away from extreme temperatures or sunlight to prevent material degradation. Proper cleaning using mild soap and water, avoiding oils or solvents, extends the lifespan and ensures the safety performance of both Class A and Class B gloves.

Cost Considerations: Class A vs. Class B Gloves

Class A gloves typically have a higher cost due to their enhanced cut resistance and advanced materials designed for heavy-duty applications, making them suitable for industries requiring maximum hand protection. In contrast, Class B gloves are more affordable and offer moderate protection, ideal for tasks with lower risk levels or budget constraints. Choosing between Class A and Class B gloves involves balancing safety requirements with budget limitations to ensure optimal cost-effectiveness without compromising hand safety.

Class A glove vs Class B glove Infographic

productdif.com

productdif.com