Safety toe boots feature steel reinforcements that offer maximum protection against heavy impacts and compression, making them ideal for demanding industrial environments. Composite toe boots use non-metal materials like Kevlar or carbon fiber, providing lighter weight and better insulation from heat and cold without compromising safety. Choosing between them depends on workplace hazards, weight preference, and electrical conductivity requirements.

Table of Comparison

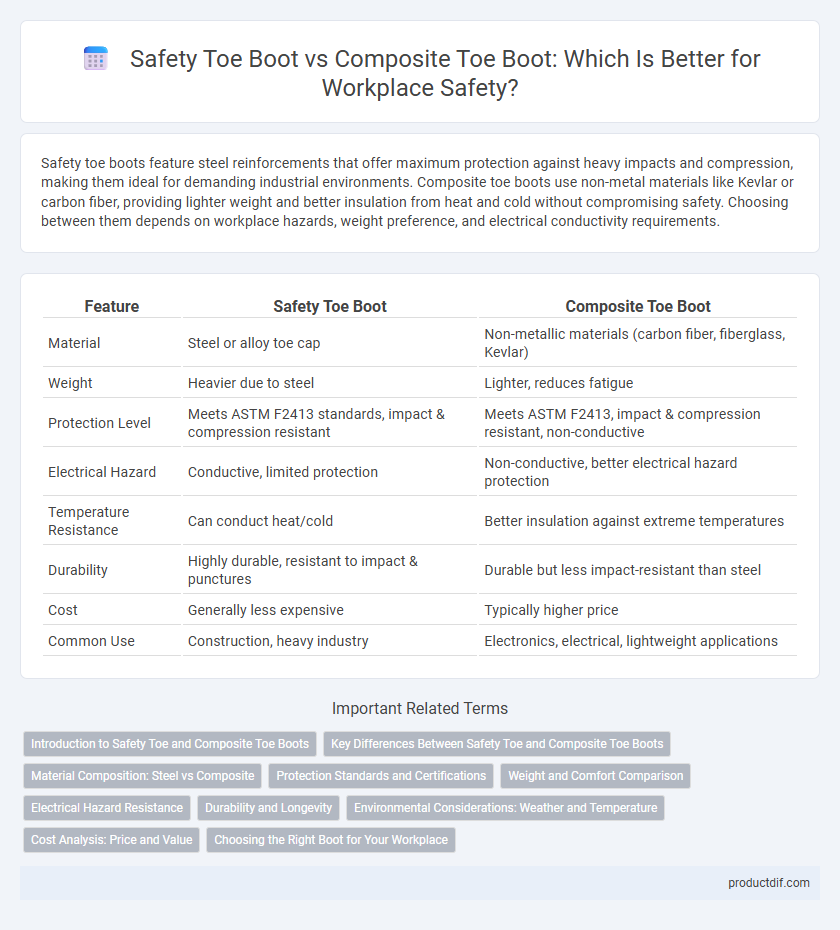

| Feature | Safety Toe Boot | Composite Toe Boot |

|---|---|---|

| Material | Steel or alloy toe cap | Non-metallic materials (carbon fiber, fiberglass, Kevlar) |

| Weight | Heavier due to steel | Lighter, reduces fatigue |

| Protection Level | Meets ASTM F2413 standards, impact & compression resistant | Meets ASTM F2413, impact & compression resistant, non-conductive |

| Electrical Hazard | Conductive, limited protection | Non-conductive, better electrical hazard protection |

| Temperature Resistance | Can conduct heat/cold | Better insulation against extreme temperatures |

| Durability | Highly durable, resistant to impact & punctures | Durable but less impact-resistant than steel |

| Cost | Generally less expensive | Typically higher price |

| Common Use | Construction, heavy industry | Electronics, electrical, lightweight applications |

Introduction to Safety Toe and Composite Toe Boots

Safety toe boots feature a steel or alloy reinforcement in the toe area to protect against heavy impact and compression hazards, meeting standards such as ASTM F2413. Composite toe boots use non-metal materials like Kevlar, carbon fiber, or plastic to offer lightweight protection while being non-conductive and metal detector friendly. Both types provide essential foot safety in industrial and construction environments, with composite toes favored for comfort and safety in electrical or metal-sensitive settings.

Key Differences Between Safety Toe and Composite Toe Boots

Safety toe boots feature steel caps that provide maximum impact resistance and durability, ideal for heavy-duty industrial environments requiring high levels of protection. Composite toe boots use non-metallic materials like Kevlar, carbon fiber, or plastic, offering lighter weight and electrical hazard protection while meeting ASTM F2413-18 standards. The primary differences lie in weight, thermal conductivity, and metal detection compatibility, with composite toes favored in environments with metal detectors and steel toes preferred for superior impact resistance.

Material Composition: Steel vs Composite

Safety toe boots typically feature a steel toe cap made from high-strength tempered steel, offering superior impact and compression resistance ideal for heavy-duty industrial environments. Composite toe boots use advanced materials such as fiberglass, carbon fiber, or Kevlar, which provide lightweight protection while being non-conductive and resistant to temperature extremes. The choice between steel and composite depends on workplace hazards, with steel excelling in maximum protection and composites favored for comfort and electrical safety.

Protection Standards and Certifications

Safety toe boots commonly meet ASTM F2413-18 standards, featuring steel toes that provide high impact resistance and compression protection. Composite toe boots adhere to similar ASTM criteria but are constructed from non-metal materials such as fiberglass or carbon fiber, offering comparable protection while meeting electrical hazard (EH) requirements. Both types typically carry ANSI or CSA certifications, ensuring compliance with workplace safety regulations.

Weight and Comfort Comparison

Safety toe boots typically feature steel toes that provide robust protection but add significant weight, often making them heavier than composite toe boots. Composite toe boots use non-metallic materials such as Kevlar or carbon fiber, resulting in lighter footwear that enhances comfort during prolonged wear. The reduced weight of composite toe boots leads to less foot fatigue, making them ideal for workers seeking a balance between safety and comfort.

Electrical Hazard Resistance

Safety toe boots with steel caps provide high electrical hazard resistance by preventing electrical current from passing through the foot, meeting ASTM F2413-18 EH standards. Composite toe boots, made from non-metallic materials like Kevlar or carbon fiber, offer similar electrical insulation benefits while being lighter and non-conductive. Both types prioritize electrical hazard protection, but composite toe boots excel in reducing heat and cold conduction compared to steel toe boots.

Durability and Longevity

Safety toe boots, typically made with steel toes, offer superior durability and impact resistance, making them ideal for heavy-duty work environments that demand high protection levels. Composite toe boots, constructed from materials like Kevlar, carbon fiber, or plastic, provide substantial durability while being lighter and more resistant to corrosion and temperature extremes. Longevity in steel toe boots generally exceeds that of composite toe boots due to the robustness of steel, though composite boots excel in environments prone to moisture or electrical hazards, potentially extending their service life under specific conditions.

Environmental Considerations: Weather and Temperature

Safety toe boots with steel toes provide superior impact resistance but may conduct cold or heat, causing discomfort in extreme weather conditions. Composite toe boots, made from non-metallic materials like Kevlar, fiberglass, or carbon fiber, offer better insulation against temperature fluctuations, making them ideal for cold or hot environments. Both types meet safety standards, but composite toe boots enhance thermal comfort and reduce temperature-related risks for prolonged wear.

Cost Analysis: Price and Value

Safety toe boots generally cost less upfront compared to composite toe boots, offering a budget-friendly option for workers who prioritize initial investment. Composite toe boots, while more expensive, provide added value through their lightweight design and non-metallic materials, which enhance comfort and pass security scans easily. Evaluating long-term benefits such as durability, safety standards compliance, and workplace suitability helps in determining overall cost-effectiveness between the two types.

Choosing the Right Boot for Your Workplace

Safety toe boots feature steel caps that provide superior impact and compression protection ideal for heavy-duty industrial environments. Composite toe boots use non-metallic materials like Kevlar or fiberglass, offering lightweight, non-conductive safety suitable for electrical or airport workers. Selecting the right boot depends on workplace hazards, weight preference, and compliance with safety standards such as ASTM F2413.

Safety toe boot vs Composite toe boot Infographic

productdif.com

productdif.com