Lockout tagout procedures ensure that machines are completely powered down and isolated from energy sources to prevent accidental startup during maintenance, significantly reducing the risk of injury. Machine guarding provides a physical barrier around moving parts to protect pet owners and animals from direct contact, minimizing mechanical hazards during operation. Combining both methods enhances overall safety in environments where pets and machinery coexist.

Table of Comparison

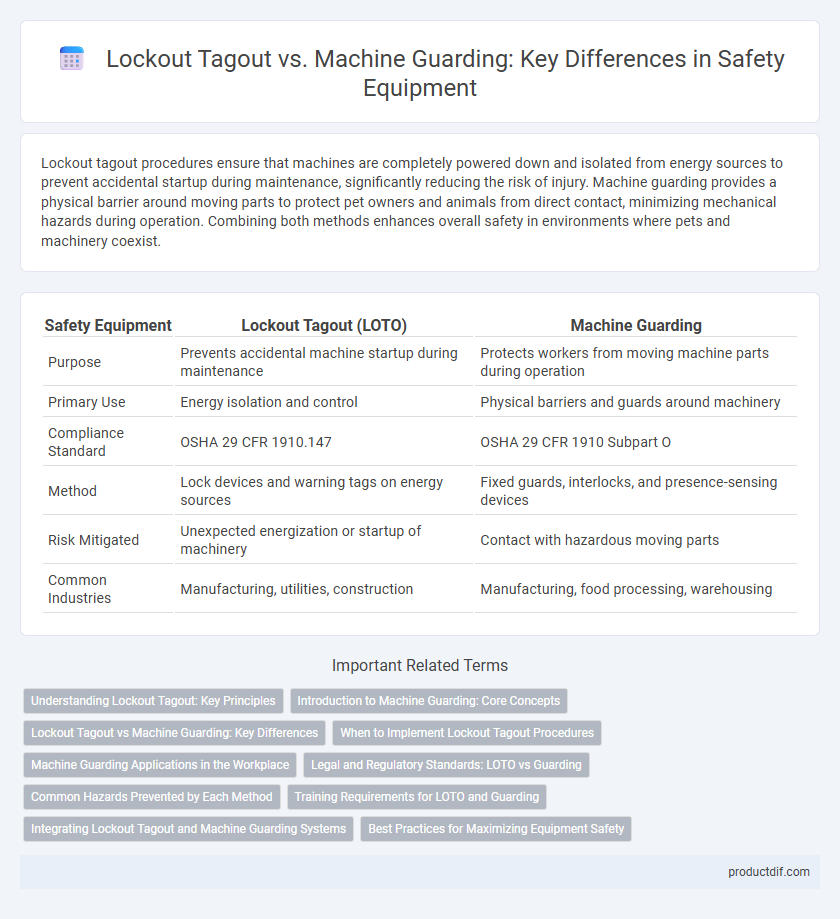

| Safety Equipment | Lockout Tagout (LOTO) | Machine Guarding |

|---|---|---|

| Purpose | Prevents accidental machine startup during maintenance | Protects workers from moving machine parts during operation |

| Primary Use | Energy isolation and control | Physical barriers and guards around machinery |

| Compliance Standard | OSHA 29 CFR 1910.147 | OSHA 29 CFR 1910 Subpart O |

| Method | Lock devices and warning tags on energy sources | Fixed guards, interlocks, and presence-sensing devices |

| Risk Mitigated | Unexpected energization or startup of machinery | Contact with hazardous moving parts |

| Common Industries | Manufacturing, utilities, construction | Manufacturing, food processing, warehousing |

Understanding Lockout Tagout: Key Principles

Lockout Tagout (LOTO) is a critical safety procedure designed to ensure machines are properly shut off and unable to be started up again before maintenance or repair work is completed. Key principles of LOTO include isolating energy sources, applying lockout devices, and using tags to warn others of ongoing maintenance. This system prevents accidental machine startup and protects workers from hazardous energy releases, differentiating it from physical barriers used in machine guarding.

Introduction to Machine Guarding: Core Concepts

Machine guarding involves the use of physical barriers, safety devices, and warning signs to protect workers from hazardous machine parts, such as moving gears, blades, and pinch points. Core concepts include identifying risk areas, implementing fixed or adjustable guards, and ensuring that guards do not interfere with machine operation while maintaining worker safety. Effective machine guarding reduces the risk of amputations, crushing injuries, and other serious workplace accidents by preventing direct contact with dangerous machinery components.

Lockout Tagout vs Machine Guarding: Key Differences

Lockout Tagout (LOTO) focuses on controlling hazardous energy by isolating power sources during maintenance to prevent accidental startup, whereas machine guarding involves physical barriers or devices designed to protect workers from moving parts during machine operation. LOTO requires strict procedural compliance for de-energizing equipment, while machine guarding provides continuous physical protection without interrupting production. Both safety measures are critical but serve distinct roles: LOTO ensures worker safety during servicing, and machine guarding protects operators during normal machine use.

When to Implement Lockout Tagout Procedures

Lockout tagout procedures should be implemented whenever maintenance or servicing of machinery involves exposure to hazardous energy sources, such as electrical, mechanical, hydraulic, or pneumatic systems, to prevent accidental startup. Machine guarding is typically used during normal operation to protect workers from moving parts, but lockout tagout is critical before any repair or inspection activities begin. OSHA standards require lockout tagout protocols to ensure employee safety during these high-risk tasks.

Machine Guarding Applications in the Workplace

Machine guarding applications in the workplace are essential for preventing employee injuries by physically isolating hazardous machine parts such as gears, blades, and pinch points. Common types of machine guards include fixed guards, interlocked guards, adjustable guards, and self-adjusting guards, each designed to provide specific protection based on the machine's operation. Effective machine guarding reduces the risk of amputations, lacerations, and crushing injuries, ensuring compliance with OSHA regulations and enhancing overall workplace safety.

Legal and Regulatory Standards: LOTO vs Guarding

Lockout tagout (LOTO) standards are governed primarily by OSHA regulation 29 CFR 1910.147, requiring specific procedures to control hazardous energy during equipment maintenance. Machine guarding regulations fall under OSHA 29 CFR 1910 Subpart O, emphasizing the design and implementation of physical barriers to prevent operator contact with hazardous machine parts. Compliance with these distinct but complementary standards ensures comprehensive workplace safety and minimizes legal liabilities.

Common Hazards Prevented by Each Method

Lockout tagout effectively prevents hazards such as unexpected machine startups and accidental energy releases during maintenance, significantly reducing the risk of electrical shocks and mechanical injuries. Machine guarding protects workers from contact with moving parts, pinch points, and flying debris, minimizing cuts, amputations, and crush injuries. Both methods are essential for comprehensive workplace safety, addressing distinct but overlapping risks associated with industrial machinery.

Training Requirements for LOTO and Guarding

Lockout Tagout (LOTO) training requires employees to understand energy isolation procedures, proper use of lockout devices, and verification of equipment de-energization to prevent accidental startup during maintenance. Machine guarding training focuses on identifying hazardous machine parts, proper installation and inspection of guards, and safe operation to protect workers from mechanical injuries. Both training programs must comply with OSHA standards 1910.147 for LOTO and 1910.212 for machine guarding to ensure workplace safety and regulatory adherence.

Integrating Lockout Tagout and Machine Guarding Systems

Integrating Lockout Tagout (LOTO) and machine guarding systems enhances workplace safety by combining physical barriers with procedural controls to prevent accidental machine startup and exposure to hazards. This integration ensures machinery is both securely isolated during maintenance and effectively shielded during operation, reducing the risk of injury. Utilizing interoperable safety protocols and advanced lockout devices alongside durable guards creates a comprehensive hazard control strategy.

Best Practices for Maximizing Equipment Safety

Lockout tagout protocols ensure maximum equipment safety by isolating energy sources during maintenance, preventing accidental startup and injury. Machine guarding provides continuous physical barriers around moving parts to protect workers from entanglement, crushing, or severing hazards. Combining comprehensive lockout tagout procedures with effective machine guarding systems maximizes overall workplace safety and compliance with OSHA regulations.

Lockout tagout vs Machine guarding Infographic

productdif.com

productdif.com