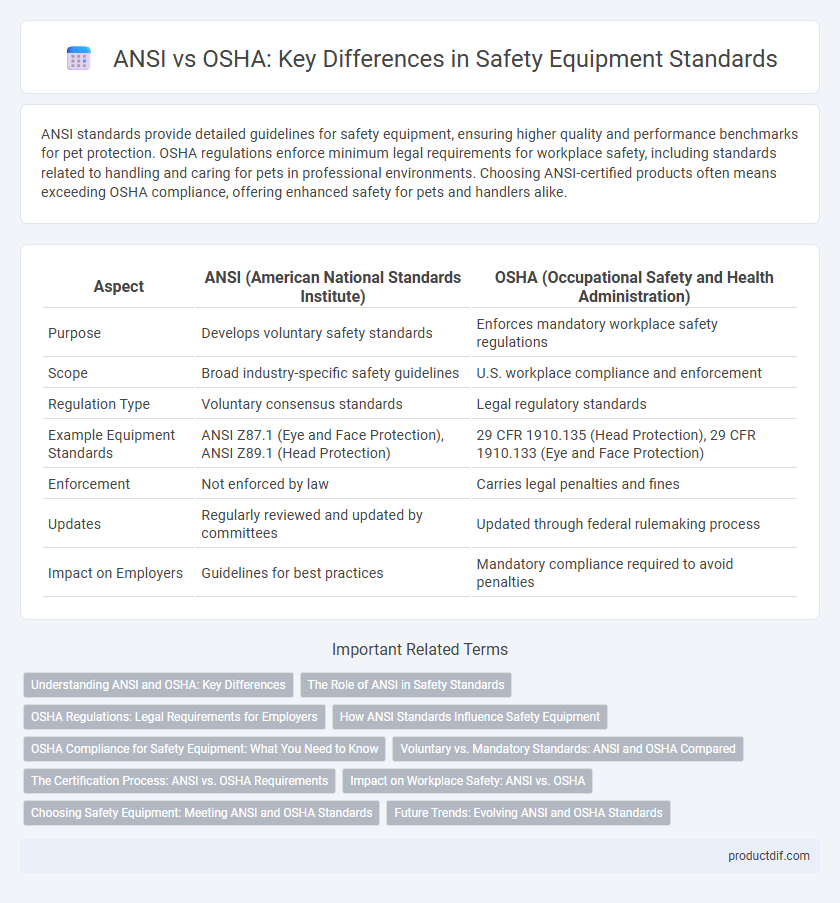

ANSI standards provide detailed guidelines for safety equipment, ensuring higher quality and performance benchmarks for pet protection. OSHA regulations enforce minimum legal requirements for workplace safety, including standards related to handling and caring for pets in professional environments. Choosing ANSI-certified products often means exceeding OSHA compliance, offering enhanced safety for pets and handlers alike.

Table of Comparison

| Aspect | ANSI (American National Standards Institute) | OSHA (Occupational Safety and Health Administration) |

|---|---|---|

| Purpose | Develops voluntary safety standards | Enforces mandatory workplace safety regulations |

| Scope | Broad industry-specific safety guidelines | U.S. workplace compliance and enforcement |

| Regulation Type | Voluntary consensus standards | Legal regulatory standards |

| Example Equipment Standards | ANSI Z87.1 (Eye and Face Protection), ANSI Z89.1 (Head Protection) | 29 CFR 1910.135 (Head Protection), 29 CFR 1910.133 (Eye and Face Protection) |

| Enforcement | Not enforced by law | Carries legal penalties and fines |

| Updates | Regularly reviewed and updated by committees | Updated through federal rulemaking process |

| Impact on Employers | Guidelines for best practices | Mandatory compliance required to avoid penalties |

Understanding ANSI and OSHA: Key Differences

ANSI (American National Standards Institute) develops voluntary consensus standards to guide safety equipment design, while OSHA (Occupational Safety and Health Administration) enforces mandatory workplace safety regulations in the United States. Understanding the differences between ANSI's performance-based standards and OSHA's compliance-driven requirements is crucial for ensuring both effective safety gear and legal adherence. Employers often use ANSI standards as benchmarks to meet OSHA's regulatory mandates and enhance worker protection.

The Role of ANSI in Safety Standards

ANSI establishes consensus-based safety standards that serve as voluntary guidelines to improve workplace safety across various industries. These standards often influence OSHA regulations by providing detailed technical criteria and best practices for personal protective equipment and hazard prevention. Collaboration between ANSI and OSHA ensures consistent safety protocols, enhancing compliance and reducing workplace injuries.

OSHA Regulations: Legal Requirements for Employers

OSHA regulations establish mandatory safety standards that employers must follow to ensure a hazard-free workplace, including requirements for personal protective equipment, hazard communication, and emergency procedures. These federal regulations carry legal enforcement authority, with non-compliance resulting in fines, penalties, or legal action. OSHA's comprehensive safety rules are designed to protect employees across all industries by setting minimum safety requirements and conducting regular inspections.

How ANSI Standards Influence Safety Equipment

ANSI standards establish rigorous safety equipment specifications that often serve as foundational benchmarks for OSHA regulations, ensuring consistent quality and effectiveness across industries. By defining performance criteria for helmets, gloves, and respiratory devices, ANSI influences manufacturers to innovate and comply with high safety thresholds. These standards contribute to workplace safety by guiding OSHA's enforcement policies and shaping regulatory requirements for protective gear.

OSHA Compliance for Safety Equipment: What You Need to Know

OSHA compliance for safety equipment mandates adherence to specific standards that ensure worker protection in various industries. Employers must regularly inspect, maintain, and provide personal protective equipment (PPE) that meets OSHA requirements to avoid citations and ensure workplace safety. Understanding OSHA regulations for safety gear, including helmets, gloves, and eye protection, is essential for reducing accidents and legal liabilities.

Voluntary vs. Mandatory Standards: ANSI and OSHA Compared

ANSI standards are voluntary guidelines developed through consensus by industry experts, promoting best practices in safety equipment design and use. OSHA regulations are mandatory requirements enforced by law to ensure workplace safety and compliance with federal standards. Employers often adopt ANSI standards as benchmarks, but must follow OSHA rules to meet legal obligations and avoid penalties.

The Certification Process: ANSI vs. OSHA Requirements

ANSI certification involves a consensus-based process that ensures safety equipment meets voluntary standards developed by industry experts, emphasizing performance and quality benchmarks. OSHA certification mandates that safety equipment complies with legally enforceable federal regulations designed to protect worker health and safety, often referencing ANSI standards within its requirements. The certification process for OSHA often includes inspection, documentation, and adherence to specific codes, while ANSI emphasizes rigorous testing and validation through accredited laboratories.

Impact on Workplace Safety: ANSI vs. OSHA

ANSI and OSHA standards both play crucial roles in workplace safety, but OSHA regulations have the force of law, ensuring mandatory compliance to protect employees from hazards. ANSI provides consensus-based guidelines that often serve as the technical foundation for OSHA standards, promoting best practices and innovation in safety equipment design. The complementary relationship between ANSI's detailed specifications and OSHA's enforceable rules significantly enhances overall safety outcomes in various industries.

Choosing Safety Equipment: Meeting ANSI and OSHA Standards

Selecting safety equipment requires strict adherence to both ANSI and OSHA standards to ensure maximum protection and regulatory compliance. ANSI sets performance criteria and testing methods for protective gear, while OSHA enforces workplace safety regulations mandating the use of equipment that meets or exceeds ANSI specifications. Prioritizing equipment certified under ANSI standards and verified by OSHA inspections reduces workplace hazards and legal liabilities effectively.

Future Trends: Evolving ANSI and OSHA Standards

ANSI and OSHA standards are increasingly integrating advanced technologies such as IoT and AI to enhance workplace safety equipment compliance. Future trends emphasize dynamic, data-driven updates to safety protocols, ensuring real-time hazard detection and response. Enhanced collaboration between ANSI and OSHA aims to harmonize standards globally, promoting proactive risk management and worker protection.

ANSI vs OSHA Infographic

productdif.com

productdif.com