Fire-resistant clothing is designed to self-extinguish and prevent ignition when exposed to flames, offering active protection in high-heat environments for pets. Flame-retardant clothing, on the other hand, contains chemicals that slow down the spread of fire but may still catch fire under prolonged exposure. Choosing the right safety gear for pets depends on the specific risk level and duration of potential flame exposure to ensure maximum protection.

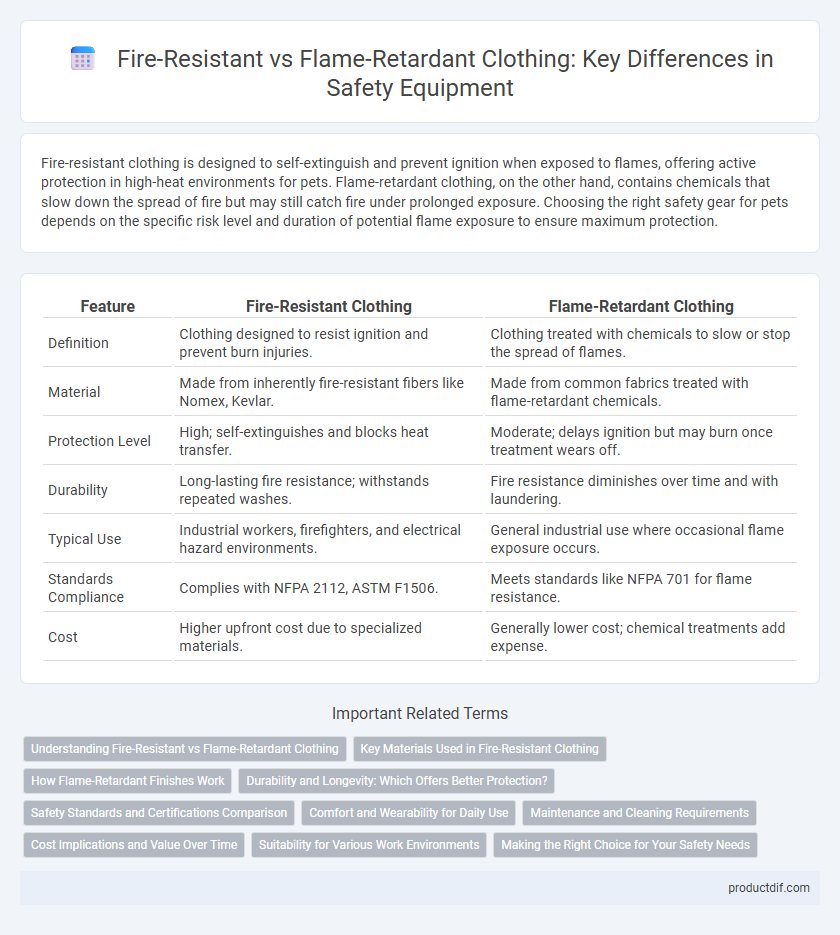

Table of Comparison

| Feature | Fire-Resistant Clothing | Flame-Retardant Clothing |

|---|---|---|

| Definition | Clothing designed to resist ignition and prevent burn injuries. | Clothing treated with chemicals to slow or stop the spread of flames. |

| Material | Made from inherently fire-resistant fibers like Nomex, Kevlar. | Made from common fabrics treated with flame-retardant chemicals. |

| Protection Level | High; self-extinguishes and blocks heat transfer. | Moderate; delays ignition but may burn once treatment wears off. |

| Durability | Long-lasting fire resistance; withstands repeated washes. | Fire resistance diminishes over time and with laundering. |

| Typical Use | Industrial workers, firefighters, and electrical hazard environments. | General industrial use where occasional flame exposure occurs. |

| Standards Compliance | Complies with NFPA 2112, ASTM F1506. | Meets standards like NFPA 701 for flame resistance. |

| Cost | Higher upfront cost due to specialized materials. | Generally lower cost; chemical treatments add expense. |

Understanding Fire-Resistant vs Flame-Retardant Clothing

Fire-resistant clothing is made from inherently non-flammable fibers that resist ignition and self-extinguish when exposed to flames, providing reliable protection for workers in high-heat environments. Flame-retardant clothing, treated with chemical coatings, slows the spread of fire and reduces burning intensity but may wear off after multiple washes, requiring frequent maintenance. Selecting the appropriate option depends on industry standards like NFPA 2112 and the specific hazards present in workplaces such as oil rigs, electrical utilities, or welding operations.

Key Materials Used in Fire-Resistant Clothing

Fire-resistant clothing primarily utilizes inherently flame-resistant fibers such as Nomex, Kevlar, and PBI, which offer durable protection by chemically resisting ignition and maintaining integrity under high temperatures. These materials are engineered to provide sustained thermal protection and prevent melt or drip hazards during exposure to flames. The advanced molecular structure of these fibers ensures that fire-resistant clothing remains effective without relying on chemical treatments, enhancing longevity and safety for industrial firefighting and electrical work.

How Flame-Retardant Finishes Work

Flame-retardant finishes work by creating a protective barrier on the fabric surface that slows down the ignition process and inhibits the spread of flames, often through chemical treatments that release flame-suppressing gases or form a char layer. These finishes are applied to fabrics to enhance their resistance to burning without altering the material's inherent properties, making them essential in flame-retardant clothing. The effectiveness of flame-retardant finishes depends on factors such as the type of chemicals used, fabric composition, and exposure conditions, ensuring improved safety in hazardous environments.

Durability and Longevity: Which Offers Better Protection?

Fire-resistant clothing typically offers greater durability as it is made from inherently heat-resistant fibers such as Nomex or Kevlar, which maintain protective properties even after multiple washes. Flame-retardant clothing relies on chemical treatments applied to fabrics, which can diminish over time and through laundering, potentially reducing long-term effectiveness. For sustained protection and longevity in hazardous environments, fire-resistant garments generally provide a more reliable safety solution.

Safety Standards and Certifications Comparison

Fire-resistant clothing complies with stringent standards such as NFPA 2112 and ASTM F1506, ensuring durability against high heat and direct flame exposure, while flame-retardant clothing often meets OSHA and IEC 61482-2 certifications for electrical arc protection and general fire resistance. NFPA 2112 certification requires garments to self-extinguish within seconds after ignition, providing verified protection crucial for industries like oil and gas. Flame-retardant clothing undergoes rigorous testing like vertical flame tests and arc flash ratings, prioritizing workplace safety in environments with potential electrical hazards.

Comfort and Wearability for Daily Use

Fire-resistant clothing offers high durability and protection by intrinsically resisting ignition, making it comfortable for extended wear due to breathable fabrics and moisture-wicking properties. Flame-retardant clothing, treated with chemical coatings, can sometimes compromise softness and flexibility, affecting comfort during daily use. Choosing fire-resistant gear ensures better wearability without sacrificing safety in industrial and emergency environments.

Maintenance and Cleaning Requirements

Fire-resistant clothing requires careful maintenance through specialized cleaning methods that preserve inherent protective fibers, often avoiding harsh chemicals and bleach to maintain its effectiveness. Flame-retardant clothing, treated with chemical coatings, may lose its protective properties if exposed to improper washing techniques, including high temperatures or abrasive detergents, necessitating adherence to manufacturer guidelines. Proper maintenance and cleaning are critical to sustaining the fire protection performance of both types, ensuring worker safety in hazardous environments.

Cost Implications and Value Over Time

Fire-resistant clothing generally entails a higher upfront cost due to specialized materials engineered to withstand direct exposure to flames, offering long-lasting protection without compromising durability. Flame-retardant clothing often costs less initially, relying on chemical treatments that may degrade after multiple washes, potentially increasing replacement frequency and overall expense. Evaluating cost implications requires assessing the value over time, with fire-resistant garments typically providing superior longevity and sustained safety benefits that justify higher initial investment.

Suitability for Various Work Environments

Fire-resistant clothing is designed to withstand high temperatures and direct exposure to flames, making it ideal for industries like firefighting, electrical work, and metalworking where sudden flash fires or electrical arcs are common. Flame-retardant clothing, treated with chemical finishes, slows the spread of fire and is suitable for environments with lower risk of direct flame contact, such as oil refineries, manufacturing plants, and laboratories. Selecting appropriate safety apparel depends on specific hazard assessments and regulatory standards like NFPA 2112 for flash fire protection or ASTM F1506 for electrical arc resistance.

Making the Right Choice for Your Safety Needs

Fire-resistant clothing is designed to self-extinguish when exposed to flame, providing long-lasting protection by maintaining its integrity under high heat conditions, whereas flame-retardant clothing contains chemicals that reduce flammability but may lose effectiveness after multiple washes. Assessing workplace hazards, such as exposure to open flames or electrical arcs, is crucial for selecting the appropriate safety gear. Prioritize certified standards like NFPA 2112 for flame-resistant fabrics to ensure optimal protection tailored to specific fire and heat risks.

Fire-resistant clothing vs Flame-retardant clothing Infographic

productdif.com

productdif.com