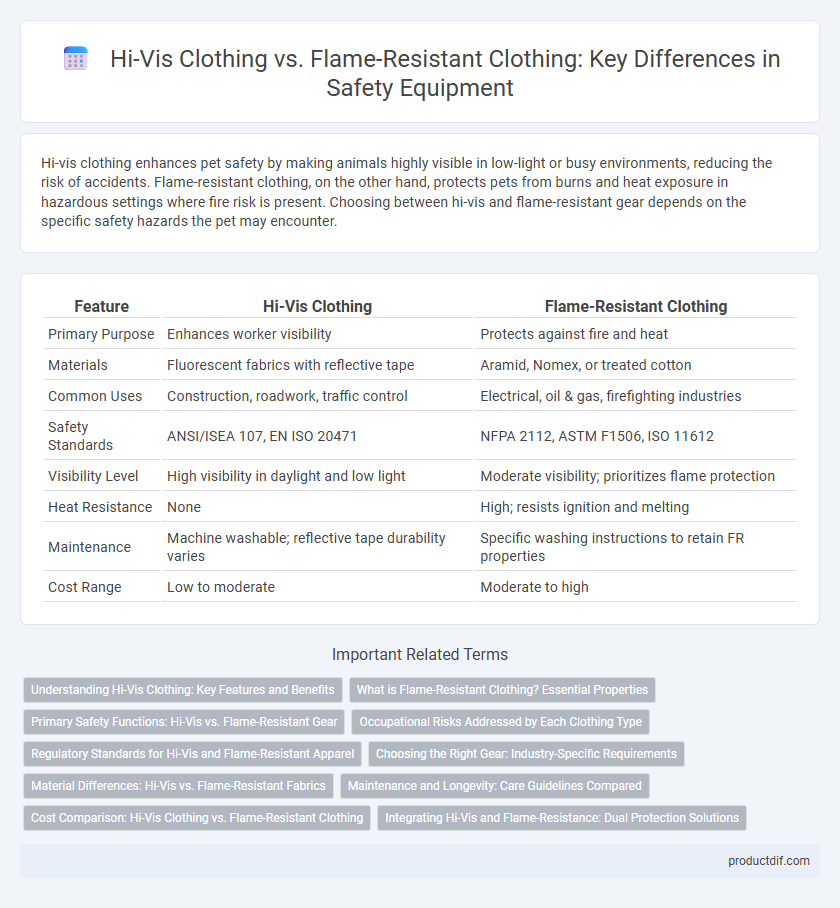

Hi-vis clothing enhances pet safety by making animals highly visible in low-light or busy environments, reducing the risk of accidents. Flame-resistant clothing, on the other hand, protects pets from burns and heat exposure in hazardous settings where fire risk is present. Choosing between hi-vis and flame-resistant gear depends on the specific safety hazards the pet may encounter.

Table of Comparison

| Feature | Hi-Vis Clothing | Flame-Resistant Clothing |

|---|---|---|

| Primary Purpose | Enhances worker visibility | Protects against fire and heat |

| Materials | Fluorescent fabrics with reflective tape | Aramid, Nomex, or treated cotton |

| Common Uses | Construction, roadwork, traffic control | Electrical, oil & gas, firefighting industries |

| Safety Standards | ANSI/ISEA 107, EN ISO 20471 | NFPA 2112, ASTM F1506, ISO 11612 |

| Visibility Level | High visibility in daylight and low light | Moderate visibility; prioritizes flame protection |

| Heat Resistance | None | High; resists ignition and melting |

| Maintenance | Machine washable; reflective tape durability varies | Specific washing instructions to retain FR properties |

| Cost Range | Low to moderate | Moderate to high |

Understanding Hi-Vis Clothing: Key Features and Benefits

Hi-vis clothing features fluorescent colors and reflective strips designed to enhance worker visibility in low-light or high-risk environments, reducing the likelihood of accidents. This safety equipment complies with standards such as ANSI/ISEA 107, ensuring optimal brightness and durability for various industries like construction and roadwork. Benefits include improved worker safety through increased visibility, easy identification, and enhanced situational awareness on job sites.

What is Flame-Resistant Clothing? Essential Properties

Flame-resistant clothing is specially designed to resist ignition and prevent the spread of fire, providing critical protection in hazardous work environments involving flames, sparks, or high heat. Essential properties include self-extinguishing fabrics, heat resistance, and durability against flames without melting or dripping, which minimize burn injuries. Unlike hi-vis clothing, which prioritizes visibility, flame-resistant garments focus on thermal protection and safety compliance in industries such as electrical, oil and gas, and firefighting.

Primary Safety Functions: Hi-Vis vs. Flame-Resistant Gear

Hi-vis clothing enhances worker visibility in low-light or high-traffic environments by using fluorescent colors and reflective strips, reducing the risk of accidents caused by poor visibility. Flame-resistant clothing is designed to resist ignition and self-extinguish when exposed to heat or flames, providing critical protection against burns and thermal hazards. Both types of safety gear serve distinct primary functions: hi-vis ensures visibility for accident prevention, while flame-resistant gear offers protection from fire-related injuries.

Occupational Risks Addressed by Each Clothing Type

Hi-vis clothing enhances worker visibility in low-light or high-traffic environments, reducing the risk of accidents involving vehicles or heavy machinery. Flame-resistant clothing protects workers from flash fires, electrical arcs, and molten metal splashes, minimizing burn injuries in environments with fire hazards. Choosing appropriate safety gear depends on the specific occupational risks, such as visibility requirements or exposure to flames and heat sources.

Regulatory Standards for Hi-Vis and Flame-Resistant Apparel

Hi-vis clothing must comply with ANSI/ISEA 107 standards, specifying criteria for color, brightness, and retroreflectivity to ensure worker visibility under various lighting conditions. Flame-resistant apparel is regulated under NFPA 2112, which sets minimum performance requirements for flame resistance and thermal protective performance to safeguard workers from flash fires. Both regulatory standards mandate rigorous testing and certification processes to validate the protective properties of the safety garments in high-risk industrial environments.

Choosing the Right Gear: Industry-Specific Requirements

Hi-vis clothing enhances visibility in low-light or high-traffic environments, making it essential for construction, roadwork, and emergency response industries where safety relies on being seen. Flame-resistant clothing is critical in industries such as oil and gas, electrical utilities, and welding, designed to protect workers from thermal hazards and reduce burn injuries. Selecting the right safety gear involves assessing specific workplace risks, regulatory standards like OSHA and NFPA, and the nature of hazards encountered in the industry.

Material Differences: Hi-Vis vs. Flame-Resistant Fabrics

Hi-vis clothing is typically made from lightweight polyester fabrics designed for high visibility and breathability, whereas flame-resistant clothing utilizes inherently flame-retardant materials such as Nomex, Kevlar, or treated cotton that self-extinguish when exposed to fire. The hi-vis fabrics prioritize color retention and reflective striping to enhance worker visibility in low-light conditions, while flame-resistant fabrics focus on durability and thermal protection to prevent burn injuries. Understanding these material differences is crucial for selecting safety gear tailored to specific workplace hazards and compliance standards.

Maintenance and Longevity: Care Guidelines Compared

Hi-vis clothing requires regular washing with mild detergents to maintain reflective properties without damaging the fluorescent fabric, typically lasting through 25-50 wash cycles. Flame-resistant clothing demands specialized cleaning procedures that avoid harsh chemicals and fabric softeners to preserve inherent flame resistance, often extending garment life for up to 100 wash cycles. Proper adherence to care guidelines for both types ensures maximum safety performance and longevity in high-risk work environments.

Cost Comparison: Hi-Vis Clothing vs. Flame-Resistant Clothing

Hi-vis clothing generally has a lower upfront cost compared to flame-resistant clothing due to simpler materials and manufacturing processes. Flame-resistant garments often require advanced fibers and chemical treatments, increasing the initial investment significantly. Over time, factors such as durability, maintenance, and regulatory compliance influence the total cost of ownership for both types of safety apparel.

Integrating Hi-Vis and Flame-Resistance: Dual Protection Solutions

Integrating Hi-vis clothing with flame-resistant materials offers dual protection by enhancing worker visibility while safeguarding against fire hazards in high-risk environments. Innovations in fabric technology enable apparel that meets stringent ANSI/ISEA visibility standards and NFPA 70E flame-resistance criteria simultaneously. Employers prioritize this combination to reduce workplace injuries related to both visibility and combustible exposure, optimizing compliance and safety protocols.

Hi-vis clothing vs Flame-resistant clothing Infographic

productdif.com

productdif.com