Single-use gloves provide optimal hygiene by reducing the risk of cross-contamination, making them ideal for medical and food handling applications. Reusable gloves offer enhanced durability and cost-effectiveness for tasks requiring prolonged protection but require thorough cleaning to maintain safety. Choosing between single-use and reusable gloves depends on the specific safety needs and frequency of use in pet care environments.

Table of Comparison

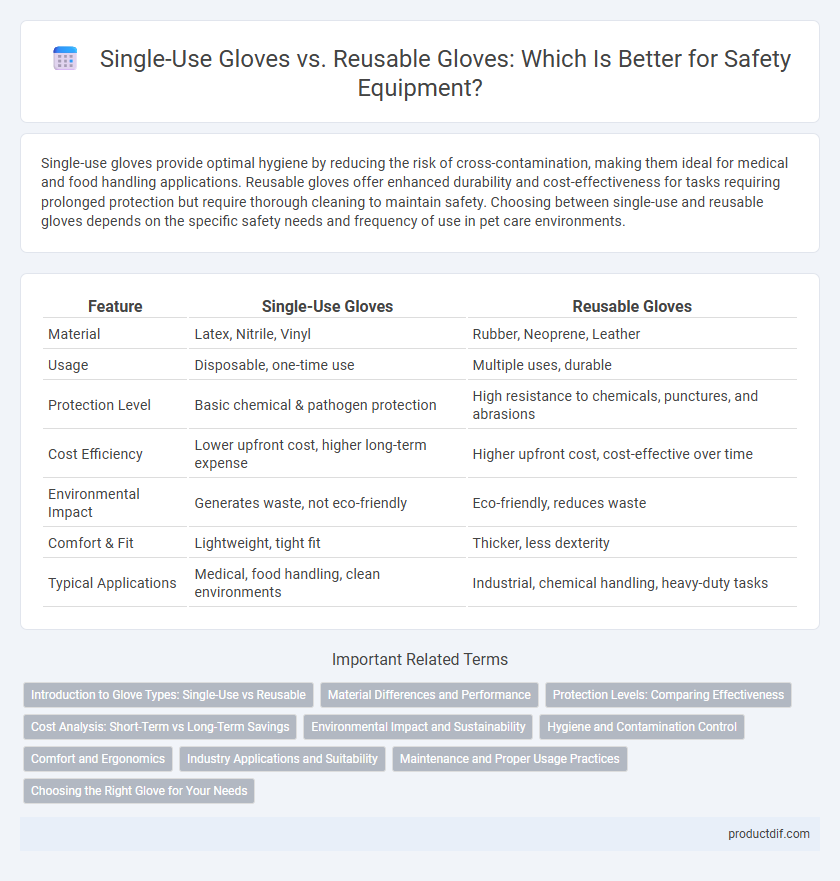

| Feature | Single-Use Gloves | Reusable Gloves |

|---|---|---|

| Material | Latex, Nitrile, Vinyl | Rubber, Neoprene, Leather |

| Usage | Disposable, one-time use | Multiple uses, durable |

| Protection Level | Basic chemical & pathogen protection | High resistance to chemicals, punctures, and abrasions |

| Cost Efficiency | Lower upfront cost, higher long-term expense | Higher upfront cost, cost-effective over time |

| Environmental Impact | Generates waste, not eco-friendly | Eco-friendly, reduces waste |

| Comfort & Fit | Lightweight, tight fit | Thicker, less dexterity |

| Typical Applications | Medical, food handling, clean environments | Industrial, chemical handling, heavy-duty tasks |

Introduction to Glove Types: Single-Use vs Reusable

Single-use gloves, typically made from latex, nitrile, or vinyl, offer high contamination control and convenience for medical, laboratory, and food handling applications by preventing cross-contamination. Reusable gloves, often constructed from durable materials such as rubber or neoprene, provide extended protection against chemicals, abrasions, and punctures in industrial and cleaning environments while offering cost-effectiveness over time. Selecting the appropriate glove type depends on specific safety requirements, exposure risks, and hygiene protocols for each task.

Material Differences and Performance

Single-use gloves are typically made from nitrile, latex, or vinyl, offering high sensitivity and disposable convenience ideal for contamination control. Reusable gloves often utilize thicker materials like neoprene, rubber, or heavy-duty latex to provide enhanced durability, chemical resistance, and prolonged wear in industrial or medical environments. Performance varies as single-use gloves excel in tactile precision and preventing cross-contamination, while reusable gloves deliver superior protection against harsh chemicals and mechanical hazards over extended use.

Protection Levels: Comparing Effectiveness

Single-use gloves provide high protection against contamination and chemicals, making them ideal for medical and laboratory settings where hygiene is critical. Reusable gloves typically offer greater durability and resistance to physical hazards like abrasion and cuts, suitable for industrial and heavy-duty tasks. Evaluating protection levels depends on the specific risk factors, with single-use gloves excelling in preventing cross-contamination and reusable gloves enhancing mechanical safety.

Cost Analysis: Short-Term vs Long-Term Savings

Single-use gloves require lower initial investment but generate higher ongoing costs due to frequent replacement, making them less cost-effective over time. Reusable gloves involve higher upfront expenses but offer significant long-term savings by reducing the need for constant repurchasing and waste management. Factoring in durability, laundering costs, and potential contamination risks provides a comprehensive cost analysis for safety equipment budgeting.

Environmental Impact and Sustainability

Single-use gloves contribute significantly to environmental waste due to their disposable nature and extensive use of non-biodegradable materials, increasing landfill volume and pollution. Reusable gloves, made from durable materials like nitrile or neoprene, offer a more sustainable option by reducing overall glove consumption and waste generation when properly maintained and sanitized. Choosing reusable gloves can lower carbon footprints and promote long-term resource conservation in safety equipment management.

Hygiene and Contamination Control

Single-use gloves provide superior hygiene by minimizing cross-contamination risks, as they are discarded immediately after each task. Reusable gloves require thorough cleaning and disinfection protocols to maintain contamination control, which may be less reliable in high-risk environments. In healthcare and food processing industries, single-use gloves are preferred for preventing pathogen transmission and ensuring strict hygiene standards.

Comfort and Ergonomics

Single-use gloves are designed to provide a snug fit and high tactile sensitivity, enhancing comfort during short-term tasks. Reusable gloves often feature padded interiors and breathable materials that improve ergonomics and reduce hand fatigue in prolonged use. Choosing between the two depends on the balance of comfort needs and task duration in safety-critical environments.

Industry Applications and Suitability

Single-use gloves provide optimal protection in healthcare and food industries where contamination control is critical, ensuring hygiene through frequent changes. Reusable gloves are well-suited for manufacturing and chemical industries, offering durability and cost-efficiency under conditions involving abrasion and chemical exposure. Selecting gloves based on industry-specific hazards ensures maximum safety and compliance with occupational health standards.

Maintenance and Proper Usage Practices

Single-use gloves require no maintenance and should be discarded immediately after use to prevent contamination and ensure hygiene. Reusable gloves demand thorough cleaning and disinfection after each use, along with regular inspections for tears or wear to maintain protective integrity. Proper storage away from direct sunlight and chemicals is essential for reusable gloves to prolong usability and preserve material strength.

Choosing the Right Glove for Your Needs

Single-use gloves provide excellent protection against contamination and are ideal for tasks requiring high hygiene standards, such as medical or food handling environments. Reusable gloves offer durability and cost-efficiency for industrial or heavy-duty applications where chemical resistance and physical protection are essential. Selecting the appropriate glove depends on factors like exposure risk, material compatibility, and frequency of use to ensure optimal safety and performance.

Single-use gloves vs Reusable gloves Infographic

productdif.com

productdif.com