ANSI-rated safety glasses prioritize impact resistance and are primarily designed to meet standards set by the American National Standards Institute, ensuring protection against flying debris for everyday industrial use. EN-rated safety glasses conform to European Norms, offering comprehensive protection including resistance to chemicals, droplets, and sometimes high-velocity impacts, making them suitable for diverse hazardous environments. Choosing between ANSI and EN-rated glasses depends on the specific safety requirements of the task and regional regulatory compliance.

Table of Comparison

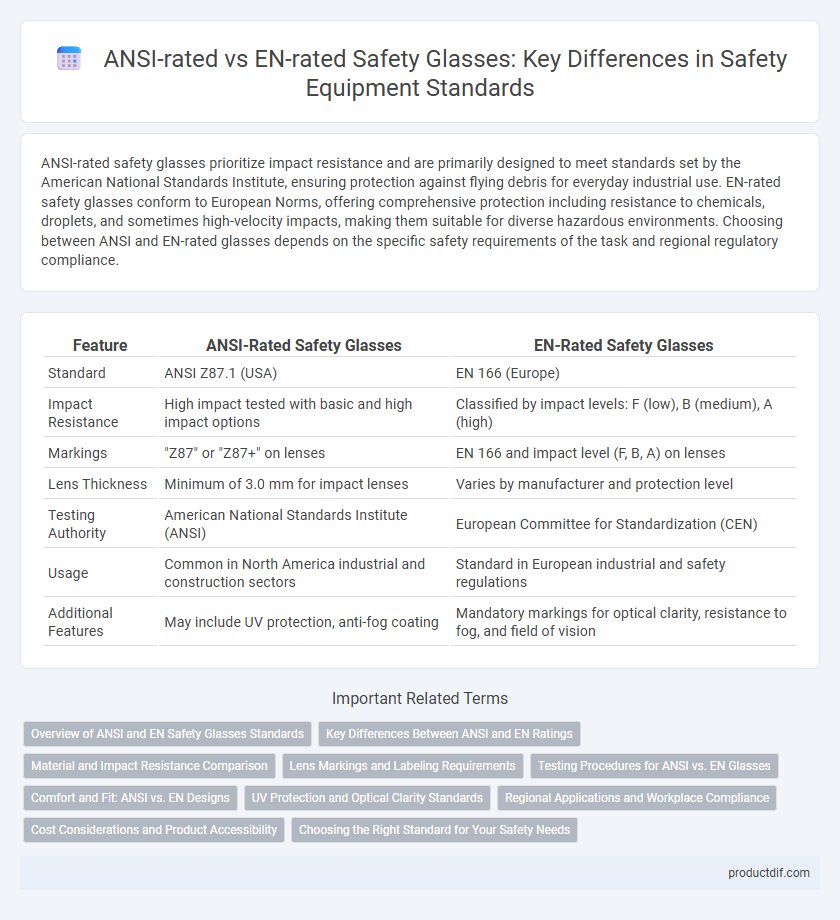

| Feature | ANSI-Rated Safety Glasses | EN-Rated Safety Glasses |

|---|---|---|

| Standard | ANSI Z87.1 (USA) | EN 166 (Europe) |

| Impact Resistance | High impact tested with basic and high impact options | Classified by impact levels: F (low), B (medium), A (high) |

| Markings | "Z87" or "Z87+" on lenses | EN 166 and impact level (F, B, A) on lenses |

| Lens Thickness | Minimum of 3.0 mm for impact lenses | Varies by manufacturer and protection level |

| Testing Authority | American National Standards Institute (ANSI) | European Committee for Standardization (CEN) |

| Usage | Common in North America industrial and construction sectors | Standard in European industrial and safety regulations |

| Additional Features | May include UV protection, anti-fog coating | Mandatory markings for optical clarity, resistance to fog, and field of vision |

Overview of ANSI and EN Safety Glasses Standards

ANSI-rated safety glasses comply with the American National Standards Institute Z87.1 standard, which emphasizes impact resistance, optical clarity, and coverage for occupational eye protection. EN-rated safety glasses adhere to the European Norm EN 166 standard, focusing on mechanical strength, resistance to various hazards, and optical quality. Both standards ensure high levels of protection but differ in testing methods, certification processes, and specific performance criteria tailored to regional industrial safety requirements.

Key Differences Between ANSI and EN Ratings

ANSI-rated safety glasses comply with American National Standards Institute standards, emphasizing impact resistance with specific tests like high mass and high velocity impact. EN-rated safety glasses follow European Norm standards, focusing on protection against mechanical hazards, chemical splashes, and optical radiation, with distinct classifications such as EN166. Key differences include the testing methods, scope of protection, and marking systems, where ANSI evaluates impact strength under strict conditions, versus EN's broader hazard protection and diverse categories.

Material and Impact Resistance Comparison

ANSI-rated safety glasses typically use polycarbonate lenses known for high impact resistance and lightweight durability, meeting the ANSI Z87.1 standard for protection against high-velocity impacts. EN-rated safety glasses, conforming to the EN166 standard, often utilize various materials including polycarbonate and glass, with rigorous testing for resistance to low and high energy impacts, ensuring comprehensive protection in diverse industrial environments. Material composition and testing protocols of these ratings directly influence their impact resistance, where ANSI emphasizes impact velocity tolerance, and EN standards focus on impact energy absorption.

Lens Markings and Labeling Requirements

ANSI-rated safety glasses feature lens markings that include the manufacturer's logo, ANSI standard number (Z87.1), and impact rating, ensuring compliance with U.S. occupational safety standards. EN-rated safety glasses require permanent markings on the lens or frame indicating conformity to EN 166 standards, including manufacturer identification, optical class, and additional protection codes. Labeling requirements for EN standards often involve CE marking to certify compliance with European Union safety regulations, emphasizing traceability and performance in hazardous environments.

Testing Procedures for ANSI vs. EN Glasses

ANSI-rated safety glasses undergo rigorous impact testing according to the ANSI Z87.1 standard, which includes high-velocity impact tests using steel balls to ensure resistance against splashes, drops, and impacts. EN-rated safety glasses comply with the EN 166 standard, requiring multiple tests such as optical clarity, robustness against mechanical strength, and resistance to high-velocity particles and molten metal splashes. These distinct testing procedures ensure that both ANSI and EN glasses meet regional safety requirements but emphasize different criteria to address specific workplace hazards.

Comfort and Fit: ANSI vs. EN Designs

ANSI-rated safety glasses often feature adjustable nose pads and temple arms designed for a more customizable fit, enhancing comfort during extended wear. EN-rated safety glasses prioritize universal sizing with flexible materials, aiming to accommodate a wide range of face shapes but may offer less adjustability. The choice between ANSI and EN designs impacts comfort, especially in prolonged use scenarios where fit precision reduces pressure points and fatigue.

UV Protection and Optical Clarity Standards

ANSI-rated safety glasses comply with the American National Standards Institute Z87.1, ensuring impact resistance and clear visibility with UV protection blocking up to 99.9% of harmful ultraviolet rays. EN-rated safety glasses meet the European Standard EN 166, emphasizing optical clarity with stringent criteria for lens quality and UV filtration, typically offering protection against UV-A, UV-B, and UV-C rays. Both ANSI and EN ratings guarantee robust UV protection and superior optical clarity, but EN 166 includes specific testing for lens distortion and light transmission that can enhance visual accuracy in critical environments.

Regional Applications and Workplace Compliance

ANSI-rated safety glasses are primarily mandated in the United States, ensuring compliance with OSHA regulations and providing impact resistance tailored to American industrial standards. EN-rated safety glasses are required across European Union countries, meeting stringent EU directives such as EN 166 for protection against mechanical hazards and chemical splashes. Selecting the appropriate rating ensures workplace compliance by aligning with regional safety regulations and industry-specific hazard protections.

Cost Considerations and Product Accessibility

ANSI-rated safety glasses generally offer more affordable options due to widespread availability in North America and a larger market presence. EN-rated safety glasses, commonly used in Europe, often incur higher costs linked to stricter certification processes and limited regional distribution. Accessibility also varies, with ANSI-rated glasses easier to source online and in local stores, whereas EN-rated versions might require specialized suppliers or international shipping.

Choosing the Right Standard for Your Safety Needs

ANSI-rated safety glasses meet the American National Standards Institute requirements, emphasizing impact resistance and protection for industrial environments in the United States. EN-rated safety glasses comply with European norms, focusing on rigorous testing for both impact and chemical splash protection, suitable for diverse European workplace conditions. Selecting the right standard depends on regional regulations and specific hazard exposures to ensure optimal eye protection and compliance.

ANSI-rated safety glasses vs EN-rated safety glasses Infographic

productdif.com

productdif.com