Arc flash suits provide maximum protection by covering the entire body with insulated layers designed to withstand high-temperature electric arc blasts, making them essential for high-risk environments. FR clothing, while flame-resistant, offers a lighter and more breathable option suitable for less intense exposure to electrical hazards. Choosing between the two depends on the specific job hazards, with arc flash suits reserved for extreme exposure and FR clothing for routine electrical safety compliance.

Table of Comparison

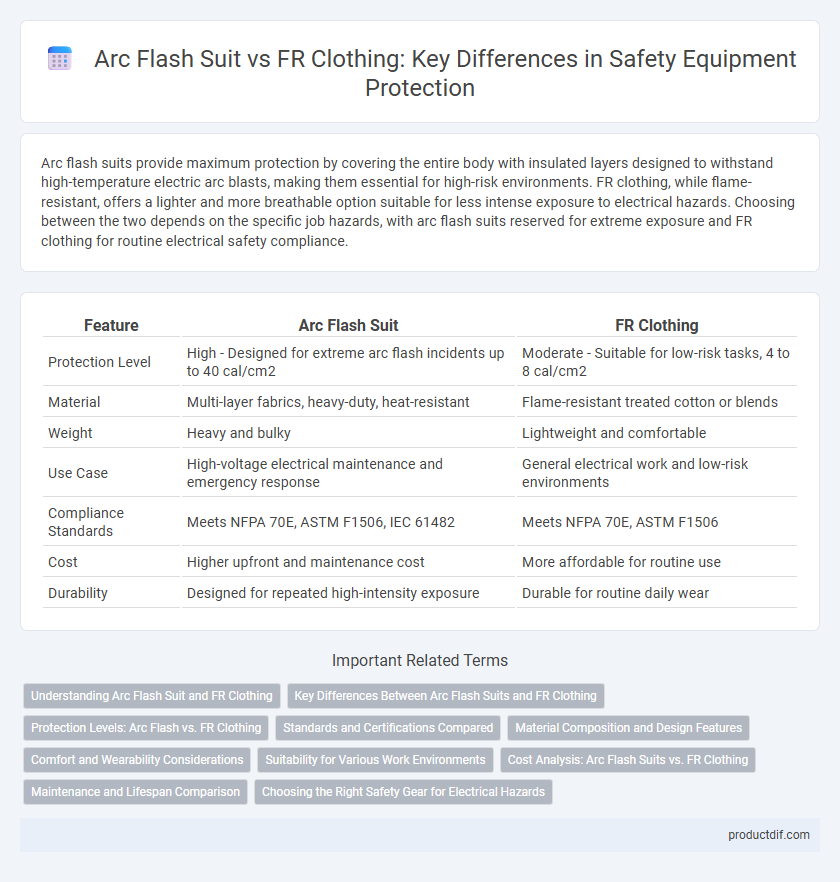

| Feature | Arc Flash Suit | FR Clothing |

|---|---|---|

| Protection Level | High - Designed for extreme arc flash incidents up to 40 cal/cm2 | Moderate - Suitable for low-risk tasks, 4 to 8 cal/cm2 |

| Material | Multi-layer fabrics, heavy-duty, heat-resistant | Flame-resistant treated cotton or blends |

| Weight | Heavy and bulky | Lightweight and comfortable |

| Use Case | High-voltage electrical maintenance and emergency response | General electrical work and low-risk environments |

| Compliance Standards | Meets NFPA 70E, ASTM F1506, IEC 61482 | Meets NFPA 70E, ASTM F1506 |

| Cost | Higher upfront and maintenance cost | More affordable for routine use |

| Durability | Designed for repeated high-intensity exposure | Durable for routine daily wear |

Understanding Arc Flash Suit and FR Clothing

Arc flash suits and flame-resistant (FR) clothing are essential for protecting workers from electrical hazards, each offering distinct levels of protection based on materials and design. Arc flash suits provide comprehensive coverage with multi-layered fabrics engineered to withstand high-intensity thermal energy from arcs, while FR clothing is typically lighter and designed to resist ignition and self-extinguish, suitable for lower-risk environments. Selecting the appropriate gear depends on incident energy levels, workplace safety standards such as NFPA 70E, and specific job hazards to ensure maximum worker safety.

Key Differences Between Arc Flash Suits and FR Clothing

Arc flash suits provide comprehensive protection with integrated face shields, hoods, and insulated gloves to guard against high-intensity electrical arcs, whereas FR (flammable resistant) clothing primarily offers resistance to fire and heat hazards without specialized arc-resistant components. Arc flash suits meet NFPA 70E standards for arc flash protection with specific ATPV (Arc Thermal Performance Value) ratings, while FR clothing focuses on fabric that self-extinguishes and limits flame spread. The choice depends on the hazard level, with arc flash suits essential for high-voltage environments requiring full-body protection, and FR clothing suitable for general fire risk scenarios.

Protection Levels: Arc Flash vs. FR Clothing

Arc flash suits are specifically designed to provide high-level protection against intense thermal energy and blast hazards associated with arc flash incidents, often rated with Arc Thermal Performance Value (ATPV) or Incident Energy Reduction Factor (IERF) to ensure safety in extreme conditions. FR (Flame Resistant) clothing offers basic protection against flames and heat exposure but generally has lower ATPV ratings and is unsuitable for full arc flash exposure without additional layers or specialized garments. Selecting appropriate protective gear depends on the electrical hazard assessment, with arc flash suits required in high-risk environments to prevent severe burn injuries while FR clothing serves well in moderate heat and flame scenarios.

Standards and Certifications Compared

Arc flash suits are tested to meet specific ASTM F1506 and NFPA 70E standards, providing comprehensive protection against electrical flash hazards with a higher arc rating compared to general FR clothing. FR clothing often complies with NFPA 2112 and ASTM F1959 standards, offering flame resistance but typically with lower arc thermal performance values (ATPV) than arc flash suits. Certifications for arc flash suits ensure full-body coverage and consistent protection in high-risk environments, whereas FR clothing certifications primarily focus on fabric performance under flame exposure.

Material Composition and Design Features

Arc flash suits are typically made from heavy-duty, multi-layered materials such as aluminized fabric or high-strength woven blends designed to reflect radiant heat and provide maximum protection against extreme heat and electric arcs. FR (flame-resistant) clothing, on the other hand, is usually constructed from inherently flame-resistant fibers like Nomex, Kevlar, or treated cotton blends that resist ignition and self-extinguish when exposed to flames. The design features of arc flash suits often include full-body coverage with reinforced seams, helmets, face shields, and gloves, while FR clothing is generally lighter, allowing for greater mobility with integrated safety features like moisture-wicking and breathability for extended wear.

Comfort and Wearability Considerations

Arc flash suits are designed with heavy-duty materials to provide maximum protection but often sacrifice comfort and breathability, leading to heat buildup during extended wear. FR (flame-resistant) clothing typically offers a lighter, more breathable fabric that enhances wearability and allows for greater mobility without compromising essential safety standards. Choosing between arc flash suits and FR clothing depends on balancing the required protection level with the need for comfort during long work shifts in high-risk environments.

Suitability for Various Work Environments

Arc flash suits provide comprehensive protection in high-risk environments with intense electrical hazards, ideal for tasks involving close proximity to live equipment. FR (flame-resistant) clothing offers versatile safety for broader industrial settings, combining comfort and protection against moderate arc flash exposures and flash fires. Selecting the right gear depends on the specific risk assessment of the work environment and the required level of arc rating and thermal protection.

Cost Analysis: Arc Flash Suits vs. FR Clothing

Arc flash suits typically incur higher initial costs compared to flame-resistant (FR) clothing due to their multi-layer construction and specialized thermal protection. FR clothing, while less expensive upfront, may require more frequent replacement because of lower durability and exposure limitations, affecting total cost of ownership. Evaluating long-term expenses, including maintenance, compliance updates, and workplace safety benefits, is essential for accurate cost analysis between arc flash suits and FR clothing.

Maintenance and Lifespan Comparison

Arc flash suits require specialized cleaning procedures often including low-temperature washing and non-abrasive detergents to maintain their protective properties, whereas FR clothing may tolerate more conventional laundering methods but still demands strict compliance with manufacturer guidelines to preserve flame resistance. The lifespan of arc flash suits is generally shorter due to their multi-layer construction and higher exposure to intense thermal hazards, typically ranging from 2 to 5 years, while FR clothing often lasts 5 to 7 years depending on wear frequency and proper maintenance. Regular inspections for damage, contamination, and compliance with NFPA 70E and ASTM F1506 standards are critical in extending the effective service life of both types of safety equipment.

Choosing the Right Safety Gear for Electrical Hazards

Arc flash suits provide comprehensive protection against intense thermal hazards by combining insulated layers with high-caliber flame-resistant (FR) fabrics, making them essential for high-risk electrical shock environments. FR clothing offers durable, non-melting materials that resist ignition and self-extinguish but is most effective for lower-level electrical risk tasks. Selecting the correct safety gear requires evaluating the arc flash hazard level, task potential, and compliance with NFPA 70E standards to ensure maximum protection and worker safety.

Arc flash suit vs FR clothing Infographic

productdif.com

productdif.com