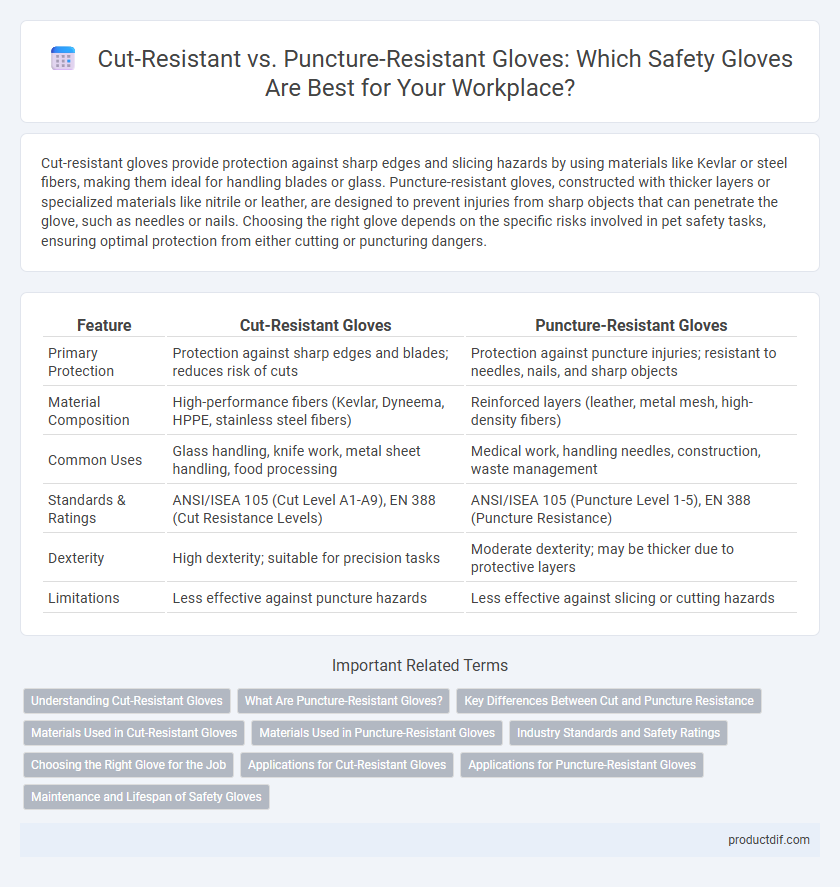

Cut-resistant gloves provide protection against sharp edges and slicing hazards by using materials like Kevlar or steel fibers, making them ideal for handling blades or glass. Puncture-resistant gloves, constructed with thicker layers or specialized materials like nitrile or leather, are designed to prevent injuries from sharp objects that can penetrate the glove, such as needles or nails. Choosing the right glove depends on the specific risks involved in pet safety tasks, ensuring optimal protection from either cutting or puncturing dangers.

Table of Comparison

| Feature | Cut-Resistant Gloves | Puncture-Resistant Gloves |

|---|---|---|

| Primary Protection | Protection against sharp edges and blades; reduces risk of cuts | Protection against puncture injuries; resistant to needles, nails, and sharp objects |

| Material Composition | High-performance fibers (Kevlar, Dyneema, HPPE, stainless steel fibers) | Reinforced layers (leather, metal mesh, high-density fibers) |

| Common Uses | Glass handling, knife work, metal sheet handling, food processing | Medical work, handling needles, construction, waste management |

| Standards & Ratings | ANSI/ISEA 105 (Cut Level A1-A9), EN 388 (Cut Resistance Levels) | ANSI/ISEA 105 (Puncture Level 1-5), EN 388 (Puncture Resistance) |

| Dexterity | High dexterity; suitable for precision tasks | Moderate dexterity; may be thicker due to protective layers |

| Limitations | Less effective against puncture hazards | Less effective against slicing or cutting hazards |

Understanding Cut-Resistant Gloves

Cut-resistant gloves are designed using advanced materials like Kevlar, Dyneema, or high-performance polyethylene (HPPE) to protect hands from sharp blades and slicers by providing resistance against cuts and slashes. These gloves are rated based on standardized scales such as ANSI/ISEA and EN388, indicating levels of cut protection, which help users select appropriate gloves for varying industrial tasks. In contrast to puncture-resistant gloves, cut-resistant gloves primarily focus on preventing injuries from sharp edges rather than resisting penetration from pointed objects.

What Are Puncture-Resistant Gloves?

Puncture-resistant gloves are designed with specially engineered materials such as Kevlar, metal mesh, or high-density polyethylene to protect hands from sharp objects that can penetrate the glove surface. These gloves provide enhanced defense against injuries caused by needles, nails, or jagged metal, making them essential for healthcare, construction, and manufacturing industries. Their durability and puncture resistance help reduce workplace accidents and injuries from hazardous tools and materials.

Key Differences Between Cut and Puncture Resistance

Cut-resistant gloves are engineered with high-performance fibers like Kevlar or Dyneema to protect against slicing hazards, while puncture-resistant gloves incorporate materials such as chainmail or thicker nitrile layers to prevent penetrations from sharp objects. Cut resistance primarily safeguards against sharp edges and blades, measured by standards like ANSI/ISEA 105, whereas puncture resistance focuses on preventing punctures from nails, needles, or splinters, often evaluated by ASTM F1342 testing. Selecting the appropriate glove depends on the specific hazard exposure, with cut-resistant gloves suited for tasks involving sharp tools and puncture-resistant gloves ideal for environments with protruding sharp points.

Materials Used in Cut-Resistant Gloves

Cut-resistant gloves typically use high-performance materials such as Kevlar, Dyneema, and stainless steel fibers to provide exceptional protection against sharp blades and edges. These materials are engineered to offer superior cut resistance while maintaining dexterity and comfort for the wearer. Advanced weaves and seamless knitting techniques enhance durability and reduce the risk of glove failure in high-risk environments.

Materials Used in Puncture-Resistant Gloves

Puncture-resistant gloves commonly feature materials such as Kevlar, high-performance polyethylene (HPPE), and stainless steel mesh, engineered to prevent sharp objects from penetrating the glove surface. These materials provide exceptional durability and enhanced protection against needles, nails, and other pointed hazards in industrial and medical settings. The combination of synthetic fibers and metal components ensures a balance of flexibility, comfort, and maximum puncture resistance.

Industry Standards and Safety Ratings

Cut-resistant gloves are rated based on standards like ASTM F2992 and EN 388, focusing on their ability to withstand blade cuts with performance levels ranging from A1 to A9 or levels 1 to 5, respectively. Puncture-resistant gloves adhere to standards such as ASTM F2878 and EN 388, which measure their resistance to penetration by sharp objects, with performance ratings emphasizing needle and point protection. Selecting gloves that meet specific industry safety ratings ensures compliance and maximizes protection against the distinct hazards of cutting versus puncturing in industrial environments.

Choosing the Right Glove for the Job

Cut-resistant gloves provide essential protection against sharp objects by using materials like Kevlar or steel fibers to prevent lacerations, making them ideal for handling knives or glass. Puncture-resistant gloves feature reinforced layers of tightly woven fibers or materials like nitrile to safeguard against penetration by nails or needles in environments with high puncture hazards. Selecting the right glove depends on the specific risk--opt for cut-resistant gloves for slicing hazards, and choose puncture-resistant gloves when protection from sharp, pointed objects is critical.

Applications for Cut-Resistant Gloves

Cut-resistant gloves are essential in industries such as glass handling, metal fabrication, and construction where workers face sharp edges and blades. These gloves offer protection against lacerations by incorporating materials like Kevlar, Dyneema, or steel fibers, enhancing durability and safety. Their application is critical in reducing workplace injuries and improving compliance with safety standards like ANSI/ISEA 105.

Applications for Puncture-Resistant Gloves

Puncture-resistant gloves are essential in industries where handling sharp objects, such as glass, metal shards, or needles, is frequent, including construction, medical, and manufacturing sectors. These gloves are designed with materials like Kevlar, steel mesh, or synthetic fibers to provide superior protection against penetration injuries. Their high puncture resistance reduces the risk of accidents when working with hazardous tools or contaminated materials, ensuring worker safety in hazardous environments.

Maintenance and Lifespan of Safety Gloves

Cut-resistant gloves require regular inspection for fabric integrity and should be cleaned according to manufacturer guidelines to maintain their protective properties. Puncture-resistant gloves often incorporate materials like Kevlar or metal mesh, demanding careful handling to avoid damage that can compromise their puncture defense. Proper storage away from heat and chemicals extends the lifespan of both types, ensuring consistent safety performance over time.

Cut-resistant gloves vs Puncture-resistant gloves Infographic

productdif.com

productdif.com