Flame-retardant clothing is designed to resist ignition and self-extinguish when exposed to flames, making it essential for protecting pets in environments with fire hazards. Arc flash clothing provides insulation against electrical blasts, minimizing burn injuries from high-voltage arcs. Choosing the right safety equipment depends on the specific risks involved, ensuring optimal protection for pets in hazardous settings.

Table of Comparison

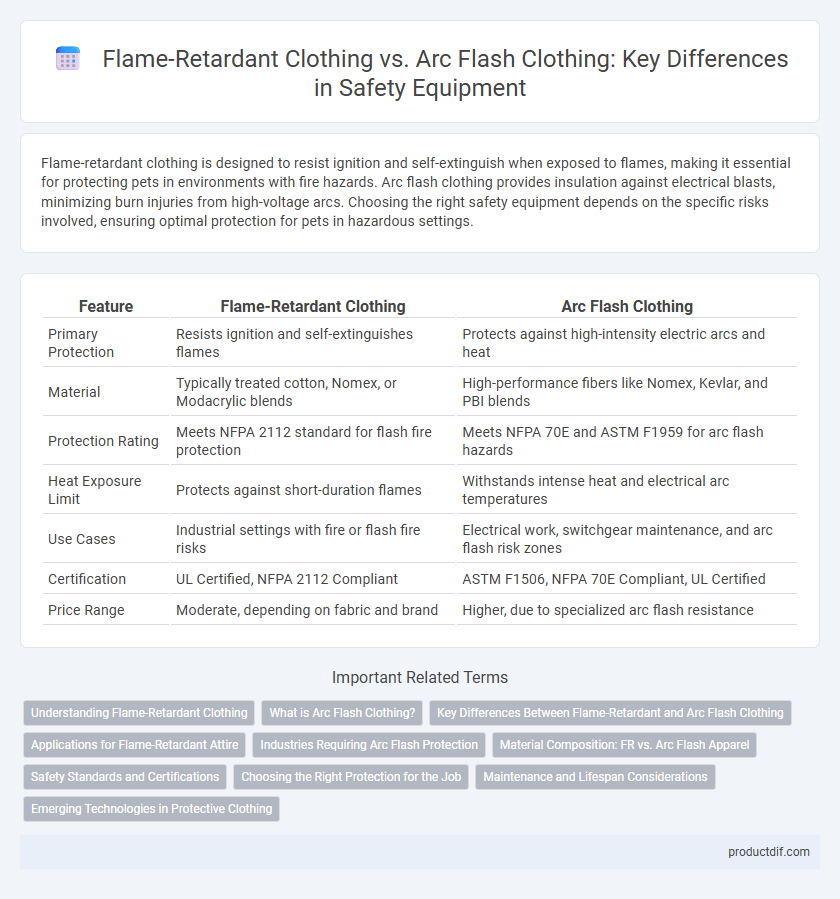

| Feature | Flame-Retardant Clothing | Arc Flash Clothing |

|---|---|---|

| Primary Protection | Resists ignition and self-extinguishes flames | Protects against high-intensity electric arcs and heat |

| Material | Typically treated cotton, Nomex, or Modacrylic blends | High-performance fibers like Nomex, Kevlar, and PBI blends |

| Protection Rating | Meets NFPA 2112 standard for flash fire protection | Meets NFPA 70E and ASTM F1959 for arc flash hazards |

| Heat Exposure Limit | Protects against short-duration flames | Withstands intense heat and electrical arc temperatures |

| Use Cases | Industrial settings with fire or flash fire risks | Electrical work, switchgear maintenance, and arc flash risk zones |

| Certification | UL Certified, NFPA 2112 Compliant | ASTM F1506, NFPA 70E Compliant, UL Certified |

| Price Range | Moderate, depending on fabric and brand | Higher, due to specialized arc flash resistance |

Understanding Flame-Retardant Clothing

Flame-retardant clothing is specifically designed to resist ignition and self-extinguish when exposed to fire, providing critical protection for workers in environments with open flames or sparks. Made from materials such as Nomex or treated cotton, this clothing reduces burn severity by preventing the fabric from melting or sticking to the skin. Unlike arc flash clothing, which is engineered to shield against electrical arc flash hazards, flame-retardant clothing primarily safeguards against thermal exposure and direct flame contact.

What is Arc Flash Clothing?

Arc flash clothing is specialized personal protective equipment designed to shield workers from electrical arc flash hazards by resisting ignition and breaking the conductive path of high-energy electrical discharges. It is rated according to the arc thermal performance value (ATPV) or energy break-open threshold, ensuring protection against severe burns in electrical environments. Unlike general flame-retardant clothing, arc flash clothing undergoes rigorous testing to meet standards such as NFPA 70E and ASTM F1506 for electrical safety compliance.

Key Differences Between Flame-Retardant and Arc Flash Clothing

Flame-retardant clothing is designed to resist ignition and self-extinguish when exposed to flames, providing protection primarily against direct flame contact and heat. Arc flash clothing offers a higher level of protection, specifically engineered to withstand intense electrical arc flash incidents by insulating against extreme heat and electrical energy. The key difference lies in their protective mechanisms: flame-retardant clothing prevents fire spread, while arc flash clothing protects against electrical burn hazards and blast pressure.

Applications for Flame-Retardant Attire

Flame-retardant clothing is essential for workers exposed to open flames, sparks, and molten metal, commonly used in industries like welding, foundries, and oil and gas. These garments provide critical protection by inhibiting ignition and preventing the spread of fire on fabrics. Unlike arc flash clothing, which is specifically designed to resist intense electrical arcs, flame-retardant attire focuses on minimizing burn injuries from direct flame contact and heat exposure.

Industries Requiring Arc Flash Protection

Industries requiring arc flash protection include electrical utilities, manufacturing plants, and construction sites where workers are exposed to high-voltage equipment and live electrical circuits. Arc flash clothing is specifically designed to withstand intense heat and thermal energy generated by electrical explosions, offering greater protection than standard flame-retardant clothing. Employers in these sectors prioritize arc flash-rated garments to comply with OSHA and NFPA 70E standards, ensuring worker safety against arc flash hazards.

Material Composition: FR vs. Arc Flash Apparel

Flame-retardant (FR) clothing is primarily made from inherently flame-resistant fibers such as Nomex, Kevlar, or treated cotton that resist ignition and self-extinguish when exposed to flames. Arc flash clothing incorporates multi-layered materials including FR fabrics combined with insulation layers designed to absorb and dissipate the intense heat and energy from electrical arcs. The material composition of arc flash apparel often includes blends of modacrylic, FR-treated cotton, and other synthetic fibers engineered to provide both thermal protection and electrical hazard resistance.

Safety Standards and Certifications

Flame-retardant clothing is designed to resist ignition and self-extinguish, adhering to safety standards such as NFPA 2112 and ASTM F1506, which ensure protection against flash fire hazards. Arc flash clothing complies with NFPA 70E and IEEE 1584 standards, providing specific protection against electrical arc flash incidents by limiting thermal energy exposure to the body. Both types of safety apparel must undergo rigorous testing and certification to meet industry requirements for worker protection in hazardous environments.

Choosing the Right Protection for the Job

Flame-retardant clothing is engineered to resist ignition and self-extinguish when exposed to direct flames, making it ideal for environments with open flames or sparks. Arc flash clothing, designed to withstand intense heat and electrical arcs, is essential for workers exposed to electrical hazards, offering critical thermal protection during arc flash incidents. Selecting the appropriate safety gear depends on assessing specific workplace risks, ensuring compliance with standards like NFPA 70E for electrical safety or ASTM F1506 for flame resistance to maximize worker protection.

Maintenance and Lifespan Considerations

Flame-retardant clothing requires regular inspection for damage and contamination to maintain its protective properties, with washing guidelines strictly followed to preserve fabric integrity and flame resistance. Arc flash clothing demands more frequent replacement due to exposure severity, as ultraviolet degradation and heat can compromise the material's arc rating over time. Proper care and timely laundering significantly extend lifespan for both, but arc flash garments often have shorter service intervals because of intense thermal stress.

Emerging Technologies in Protective Clothing

Flame-retardant clothing incorporates advanced materials like inherently flame-resistant fibers and chemical treatments to provide enhanced resistance against ignition and high heat exposure. Arc flash clothing integrates innovative fabric technologies such as phase-change materials and moisture-wicking properties to improve thermal regulation and reduce burn severity during electrical arc incidents. Emerging technologies in protective clothing emphasize smart textiles with sensors that monitor environmental conditions and wearer health, significantly advancing safety standards in hazardous work environments.

Flame-retardant clothing vs Arc flash clothing Infographic

productdif.com

productdif.com