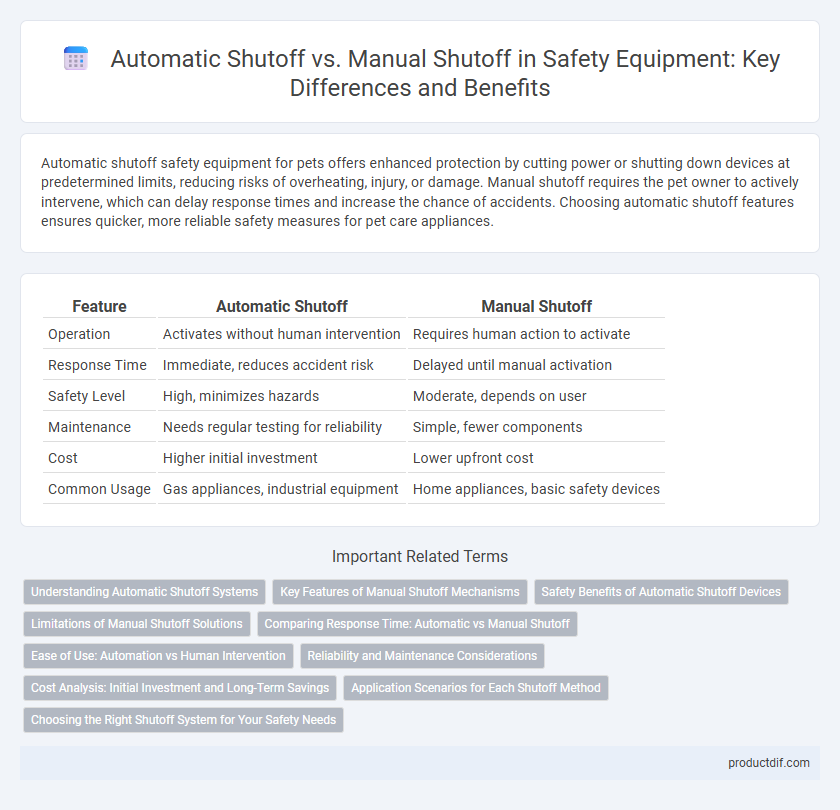

Automatic shutoff safety equipment for pets offers enhanced protection by cutting power or shutting down devices at predetermined limits, reducing risks of overheating, injury, or damage. Manual shutoff requires the pet owner to actively intervene, which can delay response times and increase the chance of accidents. Choosing automatic shutoff features ensures quicker, more reliable safety measures for pet care appliances.

Table of Comparison

| Feature | Automatic Shutoff | Manual Shutoff |

|---|---|---|

| Operation | Activates without human intervention | Requires human action to activate |

| Response Time | Immediate, reduces accident risk | Delayed until manual activation |

| Safety Level | High, minimizes hazards | Moderate, depends on user |

| Maintenance | Needs regular testing for reliability | Simple, fewer components |

| Cost | Higher initial investment | Lower upfront cost |

| Common Usage | Gas appliances, industrial equipment | Home appliances, basic safety devices |

Understanding Automatic Shutoff Systems

Automatic shutoff systems enhance safety equipment by instantly cutting power or stopping operation when detecting abnormalities such as overheating, gas leaks, or pressure changes. These systems use sensors and control units to monitor real-time conditions, reducing the risk of accidents and minimizing human error. Their integration is crucial in high-risk environments, ensuring faster response times and improved protection compared to manual shutoff methods.

Key Features of Manual Shutoff Mechanisms

Manual shutoff mechanisms provide precise control by requiring human intervention to stop equipment operation, ensuring safety during maintenance or emergency situations. They typically feature easy-to-access handles, levers, or valves designed for swift activation, minimizing response time. These devices offer reliability without dependence on electronic systems, making them essential in environments prone to power failures or technical malfunctions.

Safety Benefits of Automatic Shutoff Devices

Automatic shutoff devices enhance safety by rapidly stopping equipment or fuel flow when hazardous conditions are detected, reducing the risk of fire, explosion, or toxic exposure. These systems minimize human error and response time, ensuring immediate intervention during emergencies. Studies show that environments equipped with automatic shutoff technology experience significantly fewer accidents compared to those relying on manual shutoff methods.

Limitations of Manual Shutoff Solutions

Manual shutoff systems rely heavily on human intervention, which can lead to delayed response times during emergencies and increased risk of accidents. In high-pressure environments, the inconsistency of manual operations may result in incomplete shutdowns or operator error, compromising safety protocols. Unlike automatic shutoff devices, manual solutions lack real-time monitoring capabilities and fail to activate instantly, limiting their effectiveness in preventing equipment damage or hazardous incidents.

Comparing Response Time: Automatic vs Manual Shutoff

Automatic shutoff systems typically provide faster response times than manual shutoff mechanisms, reducing the risk of accidents and equipment damage. These systems use sensors and real-time monitoring to detect hazardous conditions instantly and activate shutoff immediately. Manual shutoff relies on human intervention, which can delay response and increase potential safety hazards in critical situations.

Ease of Use: Automation vs Human Intervention

Automatic shutoff systems enhance safety by activating without human input, reducing response time during emergencies and minimizing errors caused by delayed reactions. Manual shutoff requires user intervention, which can be slower and prone to mistakes, especially under stress. Automation provides consistent reliability and ease of use, making it preferable for critical safety equipment where immediate action is essential.

Reliability and Maintenance Considerations

Automatic shutoff systems enhance reliability by instantly stopping operations during unsafe conditions, reducing human error and downtime. Maintenance frequency for automatic systems often centers on sensor calibration and software updates, ensuring consistent performance. Manual shutoff devices require regular inspections and operator training to maintain effectiveness, with increased risk of delayed response impacting safety.

Cost Analysis: Initial Investment and Long-Term Savings

Automatic shutoff systems typically require a higher initial investment due to advanced sensors and technology integration but offer significant long-term savings by minimizing risks and reducing energy consumption. Manual shutoff devices have lower upfront costs but may lead to increased maintenance expenses and potential downtime from human error or delayed response. Evaluating both options includes balancing immediate budget constraints against potential operational efficiencies and safety improvements over time.

Application Scenarios for Each Shutoff Method

Automatic shutoff systems are essential in high-risk environments such as chemical plants and gas pipelines where immediate response to hazardous conditions prevents accidents. Manual shutoff valves are favored in settings requiring human oversight and precision control, like residential plumbing and small-scale manufacturing. Choosing between automatic and manual shutoff depends on the need for rapid emergency response versus controlled operational intervention.

Choosing the Right Shutoff System for Your Safety Needs

Automatic shutoff systems offer rapid response and reduce human error by detecting hazards and cutting power instantly, ideal for high-risk environments requiring continuous monitoring. Manual shutoff provides control and flexibility, suitable for situations where human judgment and intervention are critical to safety protocols. Assessing the specific safety risks, operational complexity, and environment will guide the choice between automatic and manual shutoff systems to optimize hazard prevention and compliance.

Automatic shutoff vs Manual shutoff Infographic

productdif.com

productdif.com