Lockout/tagout kits provide comprehensive safety solutions by isolating energy sources with tags and locks, ensuring machinery remains de-energized during maintenance. Circuit breaker lockouts specifically secure circuit breakers, preventing accidental activation and electrical hazards. Choosing between them depends on the workplace safety requirements and the types of equipment needing protection.

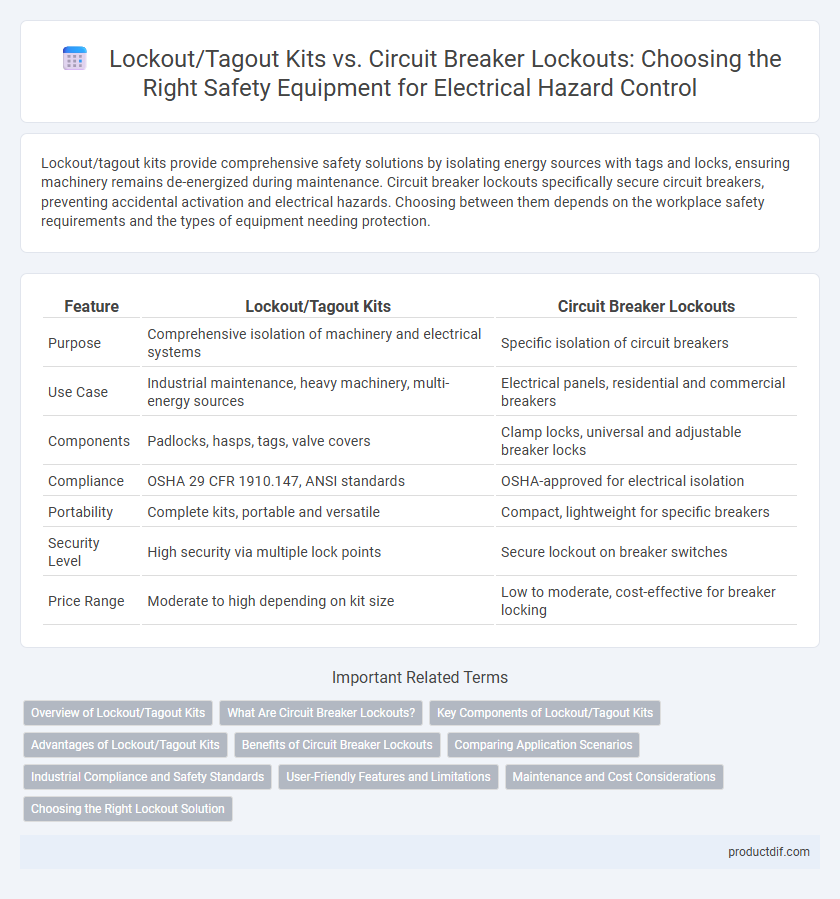

Table of Comparison

| Feature | Lockout/Tagout Kits | Circuit Breaker Lockouts |

|---|---|---|

| Purpose | Comprehensive isolation of machinery and electrical systems | Specific isolation of circuit breakers |

| Use Case | Industrial maintenance, heavy machinery, multi-energy sources | Electrical panels, residential and commercial breakers |

| Components | Padlocks, hasps, tags, valve covers | Clamp locks, universal and adjustable breaker locks |

| Compliance | OSHA 29 CFR 1910.147, ANSI standards | OSHA-approved for electrical isolation |

| Portability | Complete kits, portable and versatile | Compact, lightweight for specific breakers |

| Security Level | High security via multiple lock points | Secure lockout on breaker switches |

| Price Range | Moderate to high depending on kit size | Low to moderate, cost-effective for breaker locking |

Overview of Lockout/Tagout Kits

Lockout/tagout kits provide comprehensive safety solutions designed to isolate energy sources during maintenance or repair, ensuring worker protection by preventing accidental equipment startup. These kits typically include padlocks, tags, lockout hasps, and adapters compatible with various machinery and electrical components, offering versatility across multiple industries. Their standardized components enhance compliance with OSHA regulations and simplify the lockout/tagout process for effective workplace safety management.

What Are Circuit Breaker Lockouts?

Circuit breaker lockouts are specialized safety devices designed to secure circuit breakers in the off position, preventing accidental re-energization during maintenance. These lockouts enhance workplace safety by physically blocking the breaker handle, ensuring compliance with OSHA lockout/tagout standards. Easily attached and removed, circuit breaker lockouts are essential components in controlling hazardous energy and protecting workers from electrical injuries.

Key Components of Lockout/Tagout Kits

Lockout/tagout kits include essential components such as padlocks, lockout hasps, valve locks, and tagout labels designed to secure energy-isolating devices and communicate hazards effectively. These kits ensure comprehensive control by accommodating various equipment types and energy sources, providing a centralized solution for workplace safety compliance. Circuit breaker lockouts, while specialized, are a subset focused specifically on preventing circuit breaker operation, lacking the versatility found in complete lockout/tagout kits.

Advantages of Lockout/Tagout Kits

Lockout/tagout kits provide comprehensive safety solutions by enabling the secure isolation of various energy sources, reducing the risk of accidental equipment startup during maintenance. These kits include universal components such as padlocks, tags, and lockout devices that fit a broad range of machinery, offering greater versatility compared to circuit breaker lockouts. Their standardized design enhances compliance with OSHA regulations and promotes consistent safety practices across multiple industrial environments.

Benefits of Circuit Breaker Lockouts

Circuit breaker lockouts offer precise control by securely isolating electrical circuits, preventing accidental energization during maintenance or repairs. Their durable design ensures compatibility with various circuit breaker types, enhancing workplace safety and compliance with OSHA regulations. Utilizing circuit breaker lockouts reduces downtime and minimizes risk by providing a reliable mechanical barrier against electrical hazards.

Comparing Application Scenarios

Lockout/tagout kits are essential for comprehensive energy isolation in industrial maintenance, covering a wide range of machinery and equipment, ensuring worker safety during repairs. Circuit breaker lockouts specifically target electrical panel safety by preventing inadvertent circuit re-energization, making them ideal for electrical system maintenance. Choosing between these devices depends on the specific application needs: full equipment lockout requires a versatile kit, while targeted electrical protection benefits from specialized circuit breaker lockouts.

Industrial Compliance and Safety Standards

Lockout/tagout kits provide comprehensive control over energy sources by securing multiple types of equipment according to OSHA 1910.147 standards, ensuring industrial compliance and minimizing accidental machine start-ups. Circuit breaker lockouts are specifically designed for isolating electrical circuits, meeting NFPA 70E guidelines for electrical safety and reducing arc flash hazards. Both solutions are essential for maintaining workplace safety and adhering to regulatory requirements in industrial environments.

User-Friendly Features and Limitations

Lockout/tagout kits typically offer comprehensive user-friendly features such as clear labeling, multiple lock options, and durable tags designed for easy identification and secure application during maintenance. Circuit breaker lockouts provide a streamlined solution specifically designed for quick installation and removal on various breaker sizes, enhancing efficiency in electrical safety procedures. However, lockout/tagout kits may require more time to set up and can be bulkier, while circuit breaker lockouts are limited to electrical panels and may not accommodate non-standard breaker designs.

Maintenance and Cost Considerations

Lockout/tagout kits offer versatile maintenance solutions by accommodating various equipment types, reducing downtime through easy customization. Circuit breaker lockouts provide focused protection for electrical panels, often leading to lower initial costs but may require additional tools for comprehensive lockout needs. Evaluating total lifecycle expenses and maintenance frequency is essential for selecting between kits and specialized lockouts in safety protocols.

Choosing the Right Lockout Solution

Lockout/tagout kits provide comprehensive tools for isolating multiple types of energy sources, ensuring complete workplace safety during maintenance. Circuit breaker lockouts offer a targeted solution specifically designed to secure electrical breakers, preventing accidental re-energization. Selecting the right lockout solution depends on the complexity of the equipment, energy source variety, and compliance with OSHA safety standards.

Lockout/tagout kits vs Circuit breaker lockouts Infographic

productdif.com

productdif.com