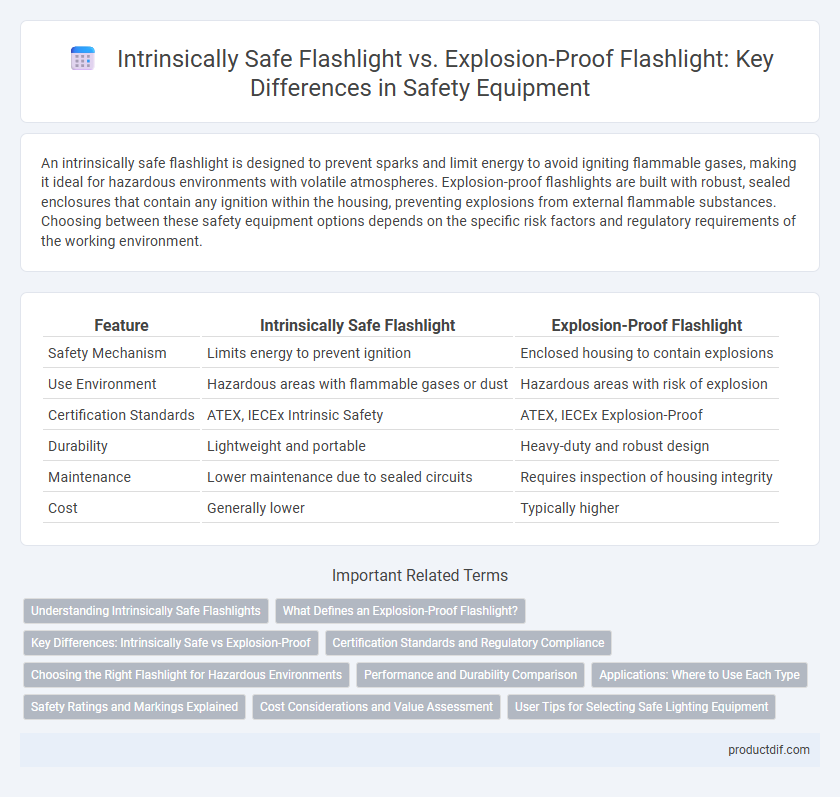

An intrinsically safe flashlight is designed to prevent sparks and limit energy to avoid igniting flammable gases, making it ideal for hazardous environments with volatile atmospheres. Explosion-proof flashlights are built with robust, sealed enclosures that contain any ignition within the housing, preventing explosions from external flammable substances. Choosing between these safety equipment options depends on the specific risk factors and regulatory requirements of the working environment.

Table of Comparison

| Feature | Intrinsically Safe Flashlight | Explosion-Proof Flashlight |

|---|---|---|

| Safety Mechanism | Limits energy to prevent ignition | Enclosed housing to contain explosions |

| Use Environment | Hazardous areas with flammable gases or dust | Hazardous areas with risk of explosion |

| Certification Standards | ATEX, IECEx Intrinsic Safety | ATEX, IECEx Explosion-Proof |

| Durability | Lightweight and portable | Heavy-duty and robust design |

| Maintenance | Lower maintenance due to sealed circuits | Requires inspection of housing integrity |

| Cost | Generally lower | Typically higher |

Understanding Intrinsically Safe Flashlights

Intrinsically safe flashlights are designed to limit energy, preventing sparks or heat that could ignite explosive gases, making them ideal for hazardous environments like chemical plants or oil refineries. These flashlights undergo rigorous testing and certification to comply with standards such as UL913 and ATEX, ensuring safe operation in zones with flammable atmospheres. Unlike explosion-proof flashlights that contain potential explosions, intrinsically safe models eliminate ignition risk by controlling internal energy, offering enhanced safety in volatile settings.

What Defines an Explosion-Proof Flashlight?

An explosion-proof flashlight is specifically engineered to contain any internal sparks or flames, preventing ignition of surrounding flammable gases or dust in hazardous environments. Its robust housing and strict compliance with safety standards, such as UL or ATEX certifications, ensure it can withstand and isolate internal explosions. These flashlights are essential for use in industries like oil and gas, mining, and chemical processing where explosive atmospheres are common.

Key Differences: Intrinsically Safe vs Explosion-Proof

Intrinsically safe flashlights limit the energy output to prevent ignition of flammable gases or dust in hazardous environments, ensuring safety by design through controlled electrical and thermal energy. Explosion-proof flashlights, on the other hand, feature rugged, sealed enclosures that contain and withstand internal explosions while preventing sparks or flames from igniting surrounding atmospheres. Key differences include intrinsic safety's reliance on energy limitation versus explosion-proof's reliance on mechanical containment, making them suitable for different hazardous area classifications and risk levels.

Certification Standards and Regulatory Compliance

Intrinsically safe flashlights comply with stringent certification standards such as ATEX, IECEx, and UL913, ensuring they limit energy to prevent ignition in hazardous environments. Explosion-proof flashlights meet rigorous certifications including UL844 and NEC Class I, Division 1, designed to contain and withstand internal explosions without igniting external gases. Both types adhere to regulatory compliance frameworks to guarantee operational safety in industries like oil and gas, mining, and chemical processing.

Choosing the Right Flashlight for Hazardous Environments

Choosing the right flashlight for hazardous environments depends on understanding the differences between intrinsically safe and explosion-proof models. Intrinsically safe flashlights are designed to limit energy to a level that cannot ignite flammable gases or dust, making them ideal for zones with continuous explosive atmospheres. Explosion-proof flashlights, made with rugged enclosures, contain explosions within the housing, suitable for environments where sparks or flames may occur but not continuous flammable conditions.

Performance and Durability Comparison

Intrinsically safe flashlights are designed to limit electrical and thermal energy to prevent ignition in hazardous environments, providing reliable performance with low power consumption and minimal heat generation. Explosion-proof flashlights feature rugged, sealed housings that can contain any internal explosions, offering superior durability and protection against mechanical impacts and harsh conditions. While intrinsically safe models excel in sensitive areas requiring strict energy control, explosion-proof flashlights deliver enhanced robustness for extreme industrial applications.

Applications: Where to Use Each Type

Intrinsically safe flashlights are designed for hazardous environments with flammable gases or dust, such as oil refineries, chemical plants, and mining operations, where any electrical spark could ignite an explosion. Explosion-proof flashlights are suited for heavy industrial sites like petrochemical facilities or grain silos, where robust construction is essential to contain any internal explosion and prevent external ignition. Selecting the proper flashlight depends on the specific hazard classification and regulatory requirements of the work environment.

Safety Ratings and Markings Explained

Intrinsically safe flashlights are designed to limit energy and prevent ignition in hazardous environments, certified with safety ratings like ATEX and IECEx indicating strict compliance with explosion prevention standards. Explosion-proof flashlights feature rugged enclosures tested to contain internal explosions without igniting external gases, marked with UL or FM approvals specifying their suitability for Class I, Division 1 hazardous locations. Understanding these safety ratings and markings ensures proper flashlight selection for environments with flammable gases or combustible dust.

Cost Considerations and Value Assessment

Intrinsically safe flashlights typically have a higher upfront cost due to their specialized design and certification requirements, making them ideal for industries with stringent safety standards. Explosion-proof flashlights, while often more durable and robust, may incur lower initial expenses but can require more frequent maintenance over time. Evaluating the total cost of ownership and operational environment is crucial to determining the best value between these two types of safety equipment.

User Tips for Selecting Safe Lighting Equipment

Choose an intrinsically safe flashlight for environments with flammable gases or vapors, as it limits electrical energy to prevent ignition. Opt for an explosion-proof flashlight when working in hazardous locations with dust or combustible materials, ensuring a sealed casing withstands internal explosions. Prioritize certifications like ATEX, IECEx, or UL to verify compliance with safety standards for your specific hazardous area requirements.

Intrinsically safe flashlight vs Explosion-proof flashlight Infographic

productdif.com

productdif.com