Dielectric boots provide essential protection against electrical hazards by insulating the wearer from electric shocks, making them ideal for electricians and utility workers. Steel-toe boots prioritize impact resistance, safeguarding feet from heavy objects and compression injuries commonly encountered in construction and industrial environments. Choosing between dielectric and steel-toe boots depends on the specific safety risks associated with the job site.

Table of Comparison

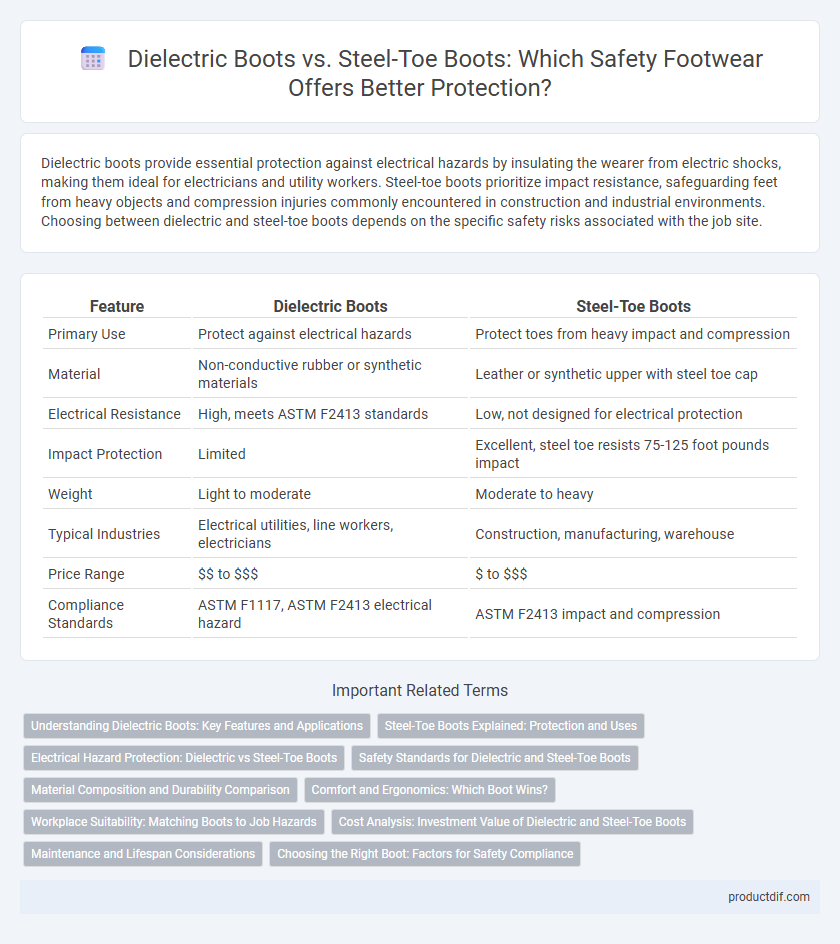

| Feature | Dielectric Boots | Steel-Toe Boots |

|---|---|---|

| Primary Use | Protect against electrical hazards | Protect toes from heavy impact and compression |

| Material | Non-conductive rubber or synthetic materials | Leather or synthetic upper with steel toe cap |

| Electrical Resistance | High, meets ASTM F2413 standards | Low, not designed for electrical protection |

| Impact Protection | Limited | Excellent, steel toe resists 75-125 foot pounds impact |

| Weight | Light to moderate | Moderate to heavy |

| Typical Industries | Electrical utilities, line workers, electricians | Construction, manufacturing, warehouse |

| Price Range | $$ to $$$ | $ to $$$ |

| Compliance Standards | ASTM F1117, ASTM F2413 electrical hazard | ASTM F2413 impact and compression |

Understanding Dielectric Boots: Key Features and Applications

Dielectric boots are designed with non-conductive materials that provide electrical insulation, protecting workers from electrical hazards in environments with live circuits or high voltage. These boots typically meet ASTM F2413 and ASTM F1117 standards, ensuring compliance with electrical safety requirements while maintaining durability and comfort. Commonly used by electricians, utility workers, and those in power generation, dielectric boots help prevent electrical shock and burn injuries during hazardous tasks.

Steel-Toe Boots Explained: Protection and Uses

Steel-toe boots feature a reinforced toe cap made from steel to protect feet from heavy falling objects, compression, and punctures, making them essential in construction, manufacturing, and industrial environments. These boots also offer impact resistance and meet safety standards such as ASTM F2413, ensuring compliance with occupational safety regulations. Their durable design, often combined with slip-resistant soles, provides comprehensive protection for workers exposed to hazardous conditions.

Electrical Hazard Protection: Dielectric vs Steel-Toe Boots

Dielectric boots provide superior electrical hazard protection by insulating the wearer from electric shocks up to specific voltage levels, making them essential for electricians and utility workers. Steel-toe boots, while offering robust impact and compression resistance, do not inherently provide electrical insulation, increasing the risk of electric shock in hazardous environments. Selecting dielectric boots is critical in workplaces with electrical hazards to ensure compliance with safety standards like ASTM F2413 and reduce the risk of electrical injuries.

Safety Standards for Dielectric and Steel-Toe Boots

Dielectric boots comply with ASTM F1117 standards to provide electrical hazard protection by insulating against high voltage, crucial for electricians and utility workers. Steel-toe boots meet ASTM F2413 standards, offering impact and compression resistance to protect feet from heavy objects and workplace hazards. Selecting boots that adhere to these specific safety standards ensures proper protection tailored to electrical risks or physical trauma in industrial environments.

Material Composition and Durability Comparison

Dielectric boots are made from non-conductive materials such as rubber or treated polymers, designed to provide electrical insulation and protect against electrical hazards, while steel-toe boots feature a reinforced steel cap embedded in the toe area to guard against heavy impact and compression injuries. In terms of durability, steel-toe boots generally offer superior resistance to physical damage including punctures and abrasions, whereas dielectric boots focus on maintaining insulating properties even under harsh conditions but may wear faster under mechanical stress. The choice between these boots depends on the specific safety requirements, with dielectric boots excelling in electrical hazard protection and steel-toe boots offering robust physical protection.

Comfort and Ergonomics: Which Boot Wins?

Dielectric boots prioritize electrical insulation and lightweight design, enhancing comfort and reducing fatigue during extended wear in high-voltage environments. Steel-toe boots offer robust impact protection but tend to be heavier and less flexible, which can lead to discomfort during prolonged use. Ergonomically, dielectric boots often provide superior cushioning and mobility, making them the preferred choice for workers requiring both safety and comfort.

Workplace Suitability: Matching Boots to Job Hazards

Dielectric boots provide superior protection against electrical hazards, making them essential for electricians and workers exposed to live circuits. Steel-toe boots offer impact resistance and are ideal for construction and industrial sites where heavy objects pose a crushing risk. Selecting the appropriate boots based on specific job hazards enhances workplace safety and prevents injury.

Cost Analysis: Investment Value of Dielectric and Steel-Toe Boots

Dielectric boots generally incur higher upfront costs due to specialized insulating materials designed to protect against electrical hazards, while steel-toe boots tend to be more affordable and widely available for general impact protection. The investment value of dielectric boots is justified in industries involving high-voltage environments, as they reduce the risk of electrical injuries and potential downtime costs. Conversely, steel-toe boots offer cost-effective durability and safety for construction and manufacturing sectors, balancing initial expense with long-term wear resistance.

Maintenance and Lifespan Considerations

Dielectric boots require regular inspection for cracks, punctures, and contamination to maintain their insulating properties, with a typical lifespan of 6 to 12 months depending on usage and care. Steel-toe boots demand consistent cleaning and sole replacement to prevent corrosion and wear, often lasting several years when properly maintained. Understanding material-specific care extends the effectiveness and safety of both types of footwear in hazardous environments.

Choosing the Right Boot: Factors for Safety Compliance

Selecting the right safety boot requires understanding the specific hazards of your work environment. Dielectric boots provide essential protection against electrical hazards by preventing current flow, making them ideal for electricians and utility workers. Steel-toe boots offer impact and compression resistance, crucial for construction and industrial sites where heavy objects pose a risk.

Dielectric boots vs Steel-toe boots Infographic

productdif.com

productdif.com