Type I helmets provide superior protection against impacts to the top of the head, making them ideal for construction and industrial work environments. Type II helmets offer enhanced lateral protection, designed to absorb blows to the sides and back of the head, which is essential in locations with greater risk of falling or flying objects. Choosing between Type I and Type II helmets depends on the specific hazards of the workplace, ensuring optimal safety for pet-related tasks and handling.

Table of Comparison

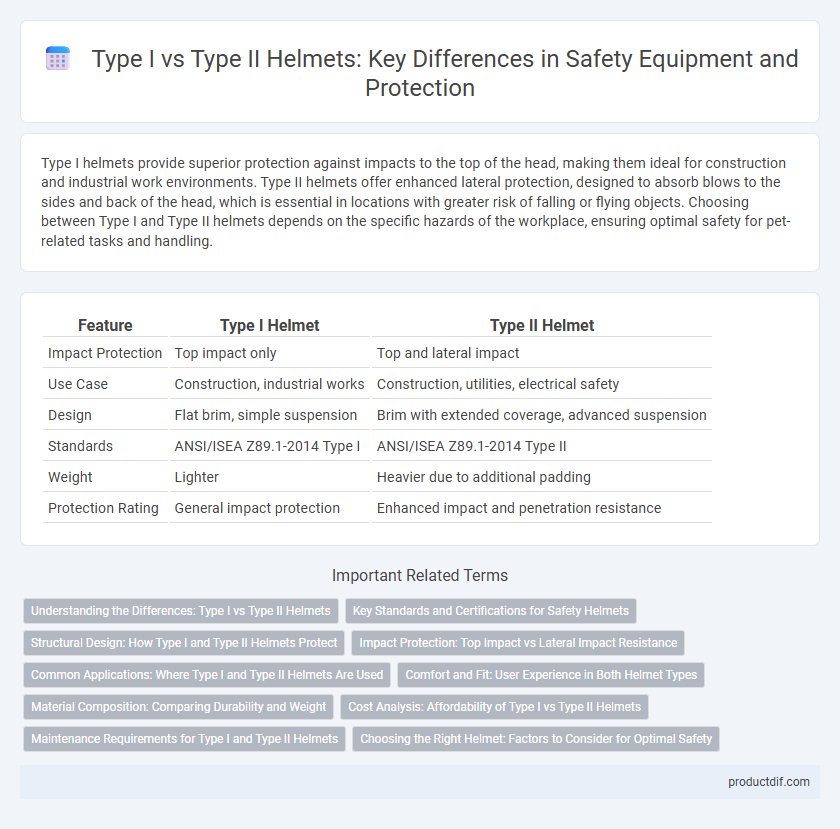

| Feature | Type I Helmet | Type II Helmet |

|---|---|---|

| Impact Protection | Top impact only | Top and lateral impact |

| Use Case | Construction, industrial works | Construction, utilities, electrical safety |

| Design | Flat brim, simple suspension | Brim with extended coverage, advanced suspension |

| Standards | ANSI/ISEA Z89.1-2014 Type I | ANSI/ISEA Z89.1-2014 Type II |

| Weight | Lighter | Heavier due to additional padding |

| Protection Rating | General impact protection | Enhanced impact and penetration resistance |

Understanding the Differences: Type I vs Type II Helmets

Type I helmets primarily offer top impact protection, designed to reduce the force of blows to the crown of the head, making them ideal for construction and industrial use. Type II helmets provide both top and lateral impact protection, featuring added cushioning and extended coverage around the sides and back, suited for situations with higher risk of sideways impacts such as in rescue operations or heavy machinery work. Choosing between Type I and Type II helmets depends on the specific safety requirements and the nature of potential hazards at the work site.

Key Standards and Certifications for Safety Helmets

Type I helmets meet the American National Standards Institute (ANSI) Z89.1 Type I certification, designed primarily for impact protection to the top of the head, commonly used in construction and industrial environments. Type II helmets comply with ANSI Z89.1 Type II standards, offering enhanced lateral impact protection, suitable for situations with hazards from the side as well as the top, and often include additional certifications such as OSHA compliance or EN 397 for international use.

Structural Design: How Type I and Type II Helmets Protect

Type I helmets feature a rigid, high-impact resistant shell with deep coverage over the head's crown and sides, optimizing protection against vertical impacts commonly encountered in construction environments. Type II helmets expand on this design with added lateral impact protection, incorporating reinforced padding and suspension systems to absorb and distribute side and angled impacts effectively. Both helmet types utilize advanced materials such as high-density polyethylene or fiberglass composites, engineered to meet stringent ANSI/ISEA Z89.1 safety standards, maximizing wearer protection in diverse hazardous settings.

Impact Protection: Top Impact vs Lateral Impact Resistance

Type I helmets are designed to provide superior protection against top impacts, making them ideal for tasks with a high risk of falling objects. Type II helmets offer enhanced lateral impact resistance, ensuring better protection for side impacts commonly encountered in construction and industrial environments. Choosing between Type I and Type II helmets depends on the specific safety requirements related to impact direction during job tasks.

Common Applications: Where Type I and Type II Helmets Are Used

Type I helmets are commonly used in construction sites and industrial environments where protection from vertical impacts is critical. Type II helmets are preferred in settings such as forestry, utilities, and electrical work where lateral impact protection is required. Both types comply with ANSI/ISEA Z89.1 standards but serve distinct safety roles based on workplace hazards.

Comfort and Fit: User Experience in Both Helmet Types

Type I helmets provide enhanced overhead protection but often feel bulkier and less ventilated, which may reduce comfort during extended use. Type II helmets offer improved side impact protection with a more ergonomic design, resulting in a snugger fit and better airflow, increasing comfort for users engaged in dynamic activities. User experience shows that Type II helmets generally deliver superior comfort and fit, especially for prolonged wear in active environments.

Material Composition: Comparing Durability and Weight

Type I helmets typically feature a hard outer shell made from fiberglass or polycarbonate, offering enhanced durability while maintaining moderate weight suitable for impact protection from top blows. Type II helmets often incorporate expanded polystyrene (EPS) foam liners with polycarbonate shells, optimizing energy absorption for lateral impacts but generally resulting in slightly higher weight due to additional padding. The material composition of Type I helmets favors durability and lightweight performance for overhead impact, whereas Type II helmets prioritize lateral impact resistance with a trade-off in added weight.

Cost Analysis: Affordability of Type I vs Type II Helmets

Type I helmets generally cost less than Type II helmets due to simpler design and lower manufacturing complexity, making them more affordable for budget-conscious buyers. Type II helmets, offering enhanced lateral protection and compliance with stricter occupational safety standards, involve higher production costs reflected in their price. Choosing between Type I and Type II helmets depends on balancing safety needs with budget constraints, where Type I suits basic impact protection while Type II provides comprehensive safety at a premium cost.

Maintenance Requirements for Type I and Type II Helmets

Type I helmets require regular inspection for cracks, shell integrity, and suspension system wear to ensure optimal impact protection primarily from vertical impacts. Type II helmets demand more rigorous maintenance due to their design for both lateral and vertical impact protection, necessitating frequent checks of the extended lateral coverage and reinforced padding. Both helmet types benefit from cleaning with mild soap and water, but Type II helmets often have additional components, such as face shields or ear protection, which require specialized care to maintain safety standards.

Choosing the Right Helmet: Factors to Consider for Optimal Safety

Type I helmets provide top impact protection primarily for falls, making them suitable for construction sites with overhead hazards, while Type II helmets are designed to offer protection against lateral impacts often encountered in industrial environments. When choosing the right helmet, consider the specific risk factors of your work environment, such as the likelihood of side impacts, falling objects, and electrical hazards. Compliance with OSHA and ANSI standards ensures the helmet meets safety criteria for your industry, enhancing worker protection and reducing injury risk.

Type I helmet vs Type II helmet Infographic

productdif.com

productdif.com