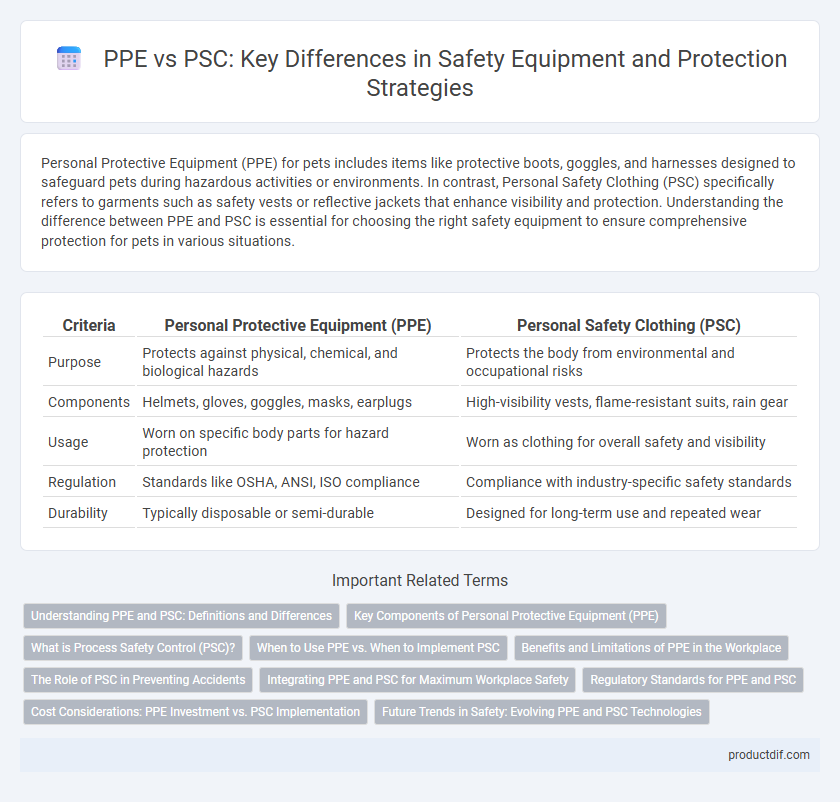

Personal Protective Equipment (PPE) for pets includes items like protective boots, goggles, and harnesses designed to safeguard pets during hazardous activities or environments. In contrast, Personal Safety Clothing (PSC) specifically refers to garments such as safety vests or reflective jackets that enhance visibility and protection. Understanding the difference between PPE and PSC is essential for choosing the right safety equipment to ensure comprehensive protection for pets in various situations.

Table of Comparison

| Criteria | Personal Protective Equipment (PPE) | Personal Safety Clothing (PSC) |

|---|---|---|

| Purpose | Protects against physical, chemical, and biological hazards | Protects the body from environmental and occupational risks |

| Components | Helmets, gloves, goggles, masks, earplugs | High-visibility vests, flame-resistant suits, rain gear |

| Usage | Worn on specific body parts for hazard protection | Worn as clothing for overall safety and visibility |

| Regulation | Standards like OSHA, ANSI, ISO compliance | Compliance with industry-specific safety standards |

| Durability | Typically disposable or semi-durable | Designed for long-term use and repeated wear |

Understanding PPE and PSC: Definitions and Differences

Personal Protective Equipment (PPE) includes wearable gear such as helmets, gloves, and goggles designed to safeguard workers from physical, chemical, and biological hazards. Protective Safety Clothing (PSC) refers specifically to specialized garments that provide protection against environmental risks like fire, chemicals, and extreme temperatures. Distinguishing PPE from PSC is essential for selecting the appropriate safety measures, with PPE covering a broader range of protective items and PSC focusing primarily on clothing-based protection.

Key Components of Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) comprises key components such as helmets, gloves, safety goggles, ear protection, and respiratory devices designed to minimize exposure to workplace hazards. Unlike Personal Safety Components (PSC), PPE's primary function is to create a physical barrier against injuries from chemical, mechanical, electrical, and environmental risks. Effective PPE selection depends on hazard assessment, durability, ergonomic design, and compliance with regulatory standards like OSHA and ANSI.

What is Process Safety Control (PSC)?

Process Safety Control (PSC) refers to a systematic approach designed to prevent industrial accidents by managing hazards associated with chemical processes and equipment. PSC integrates engineering controls, operational procedures, and safety management practices to minimize risks of fires, explosions, and toxic releases in high-hazard industries. Unlike Personal Protective Equipment (PPE) that protects individuals during exposure, PSC aims to eliminate or reduce process hazards at their source for overall workplace safety.

When to Use PPE vs. When to Implement PSC

Personal Protective Equipment (PPE) should be used when hazards cannot be completely eliminated and provide a last line of defense against injury or exposure in the workplace. Process Safety Controls (PSC) are implemented proactively to manage risks by controlling or eliminating hazards at the source, supporting safer operational procedures and preventing incidents before PPE becomes necessary. Employers must assess the risk levels and apply PSC for hazard mitigation first, resorting to PPE when engineering controls and administrative measures are insufficient.

Benefits and Limitations of PPE in the Workplace

Personal Protective Equipment (PPE) offers immediate protection against workplace hazards by creating a physical barrier between the worker and potential risks, thereby reducing injuries from falls, chemicals, or debris. Its limitations include reliance on proper usage and maintenance, potential discomfort, and inability to eliminate hazards at the source, which can lead to inconsistent protection levels. Unlike Process Safety Controls (PSC) that focus on hazard elimination or engineering controls, PPE serves as the last line of defense, emphasizing individual protection rather than systemic risk reduction.

The Role of PSC in Preventing Accidents

PSC (Personal Safety Clothing) plays a critical role in accident prevention by providing specialized protection against workplace hazards such as chemical exposure, extreme temperatures, and mechanical impacts. Unlike general PPE (Personal Protective Equipment), PSC is designed to meet stringent safety standards and enhance durability, comfort, and visibility, thereby reducing the risk of injuries and fatalities. Effective use of PSC integrates advanced materials and ergonomic design to ensure continuous protection and compliance with occupational safety regulations.

Integrating PPE and PSC for Maximum Workplace Safety

Integrating Personal Protective Equipment (PPE) with Personal Safety Controls (PSC) creates a comprehensive safety framework that minimizes workplace hazards and enhances employee protection. PPE serves as the last line of defense against physical risks, while PSC includes policies, training, and engineering controls that proactively reduce exposure to hazards. Combining these elements ensures both preventive measures and protective barriers, maximizing workplace safety and compliance with industry regulations.

Regulatory Standards for PPE and PSC

Personal Protective Equipment (PPE) and Protective Safety Clothing (PSC) are governed by stringent regulatory standards to ensure worker safety across various industries. PPE standards such as OSHA 1910 and ANSI Z87.1 specify requirements for helmets, gloves, and eye protection, while PSC standards often align with ISO 13688 and EN 340, emphasizing fabric durability, flame resistance, and visibility. Compliance with these regulations is critical for minimizing workplace hazards and enhancing overall safety performance.

Cost Considerations: PPE Investment vs. PSC Implementation

Investing in Personal Protective Equipment (PPE) requires ongoing expenses for replacements, maintenance, and compliance updates, potentially increasing long-term costs. Personal Safety Controls (PSC) implementation may demand higher initial capital for engineering controls or automation but often reduces recurring expenditures by minimizing hazard exposure and reliance on PPE. Evaluating overall safety budgets involves balancing immediate PPE investments against sustainable PSC solutions that improve workplace safety efficiency.

Future Trends in Safety: Evolving PPE and PSC Technologies

Future trends in safety equipment highlight advanced PPE incorporating smart sensors and wearable technology to enhance real-time hazard detection and worker health monitoring. PSC technologies are evolving with integrated automation and robotics to minimize human exposure to dangerous tasks while optimizing operational safety. The convergence of AI-driven PPE and PSC systems promises a new era of proactive and adaptive workplace safety solutions.

PPE vs PSC Infographic

productdif.com

productdif.com