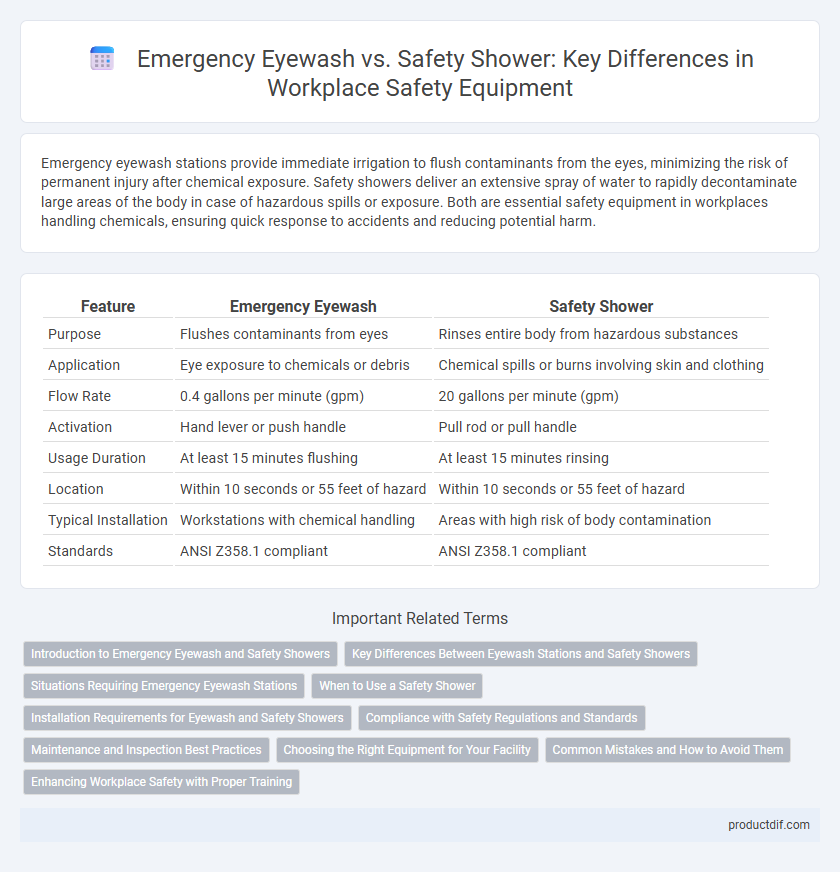

Emergency eyewash stations provide immediate irrigation to flush contaminants from the eyes, minimizing the risk of permanent injury after chemical exposure. Safety showers deliver an extensive spray of water to rapidly decontaminate large areas of the body in case of hazardous spills or exposure. Both are essential safety equipment in workplaces handling chemicals, ensuring quick response to accidents and reducing potential harm.

Table of Comparison

| Feature | Emergency Eyewash | Safety Shower |

|---|---|---|

| Purpose | Flushes contaminants from eyes | Rinses entire body from hazardous substances |

| Application | Eye exposure to chemicals or debris | Chemical spills or burns involving skin and clothing |

| Flow Rate | 0.4 gallons per minute (gpm) | 20 gallons per minute (gpm) |

| Activation | Hand lever or push handle | Pull rod or pull handle |

| Usage Duration | At least 15 minutes flushing | At least 15 minutes rinsing |

| Location | Within 10 seconds or 55 feet of hazard | Within 10 seconds or 55 feet of hazard |

| Typical Installation | Workstations with chemical handling | Areas with high risk of body contamination |

| Standards | ANSI Z358.1 compliant | ANSI Z358.1 compliant |

Introduction to Emergency Eyewash and Safety Showers

Emergency eyewash stations provide immediate flushing of the eyes to remove hazardous contaminants, critical for preventing eye injuries in workplaces handling chemicals or particulates. Safety showers deliver a full-body rinse to quickly wash off harmful substances from skin and clothing, reducing the risk of chemical burns and absorption. Both systems are essential components of workplace safety protocols, designed to minimize injury severity during chemical exposure incidents.

Key Differences Between Eyewash Stations and Safety Showers

Emergency eyewash stations provide targeted flushing to remove contaminants from eyes quickly, while safety showers deliver a full-body rinse to wash off hazardous substances from skin and clothing. Eyewash stations typically activate with a handheld or pedal mechanism, offering low-pressure water flow suitable for delicate eye tissue, whereas safety showers operate with a pull handle, releasing high-volume water to rapidly drench the body. Understanding these key differences ensures proper selection and placement of safety equipment in hazardous work environments to minimize injury risks effectively.

Situations Requiring Emergency Eyewash Stations

Emergency eyewash stations are essential in situations where hazardous chemicals or particles may come into direct contact with the eyes, such as laboratories, manufacturing plants, and chemical processing facilities. These stations provide immediate flushing to prevent serious eye injuries and reduce the risk of long-term damage. Situations involving corrosive liquids, toxic dust, or accidental splashes demand quick access to eyewash units to maintain workplace safety and compliance with OSHA standards.

When to Use a Safety Shower

Use a safety shower when hazardous chemicals come into contact with large areas of the body or clothing, requiring immediate and thorough flushing to minimize chemical burns and contamination. Safety showers deliver a high volume of water to quickly rinse off harmful substances, making them essential in laboratories, industrial settings, and chemical plants. They complement emergency eyewash stations, which are specifically designed for eye and face irrigation but are insufficient for widespread contamination.

Installation Requirements for Eyewash and Safety Showers

Emergency eyewash stations require installation within 10 seconds or approximately 55 feet of hazardous areas, ensuring immediate accessibility and must provide tepid water between 60degF and 100degF to prevent injury. Safety showers demand a minimum flow rate of 20 gallons per minute at 30 psi and should be installed so users can reach them within 10 seconds, with heads positioned at least 82 inches above the floor for effective decontamination. Both must have hands-free operation mechanisms and clear, unobstructed paths in compliance with ANSI Z358.1 standards to maximize user safety during chemical exposure incidents.

Compliance with Safety Regulations and Standards

Emergency eyewash stations and safety showers are both critical safety equipment designed to comply with OSHA, ANSI Z358.1, and EPA standards for workplace emergency response. Emergency eyewash units provide immediate flushing of hazardous substances from the eyes, meeting requirements for activation within 10 seconds and delivering a continuous flow of lukewarm water for at least 15 minutes. Safety showers are mandated for accidental exposure to harmful chemicals on the body, ensuring rapid drenching to minimize injury, with water flow rates of 20 gallons per minute and accessibility within 10 seconds from the hazard area.

Maintenance and Inspection Best Practices

Regular maintenance and inspection of emergency eyewash stations require flushing stagnant water weekly to prevent bacterial growth and checking water flow to ensure immediate availability. Safety shower systems must undergo monthly activation to verify proper water flow and pressure, with thorough inspection of drain systems to avoid flooding hazards. Both safety devices demand clear signage, unobstructed access, and prompt repair of any identified malfunctions to comply with OSHA and ANSI Z358.1 standards.

Choosing the Right Equipment for Your Facility

Selecting the appropriate safety equipment for your facility depends on the type and severity of potential chemical exposures; emergency eyewash stations are essential for flushing contaminants from the eyes, while safety showers provide full-body decontamination for larger chemical spills. OSHA standards require both devices in workplaces handling hazardous substances to ensure rapid response and minimize injury. Proper placement, accessibility, and regular maintenance enhance the effectiveness of emergency eyewash and safety shower systems in protecting employees.

Common Mistakes and How to Avoid Them

Emergency eyewash stations are often mistaken for safety showers, yet they serve distinct purposes--eyewash units flush contaminants from the eyes while safety showers rinse the entire body. A common mistake is installing eyewash stations too far from chemical exposure areas, reducing response time and effectiveness; placement within 10 seconds reach is critical. Regular maintenance and employee training on proper use prevent misuse and ensure immediate decontamination during chemical emergencies.

Enhancing Workplace Safety with Proper Training

Proper training in the use of emergency eyewash stations and safety showers significantly enhances workplace safety by ensuring employees respond quickly to chemical exposures and reduce injury severity. Emergency eyewash stations provide immediate flushing for eye contaminants, while safety showers deliver full-body decontamination for hazardous substance exposure. Regular drills and education on these safety equipment increase preparedness, minimize downtime, and support compliance with OSHA standards.

Emergency eyewash vs Safety shower Infographic

productdif.com

productdif.com