Boots with steel toes provide superior impact resistance and durability, making them ideal for heavy-duty environments where protection from falling objects is crucial. Boots with composite toes, often lighter and non-metallic, offer excellent electrical hazard protection and are more comfortable for extended wear, especially in hot or wet conditions. Choosing between the two depends on the specific safety requirements and workplace conditions, balancing protection, weight, and environmental factors.

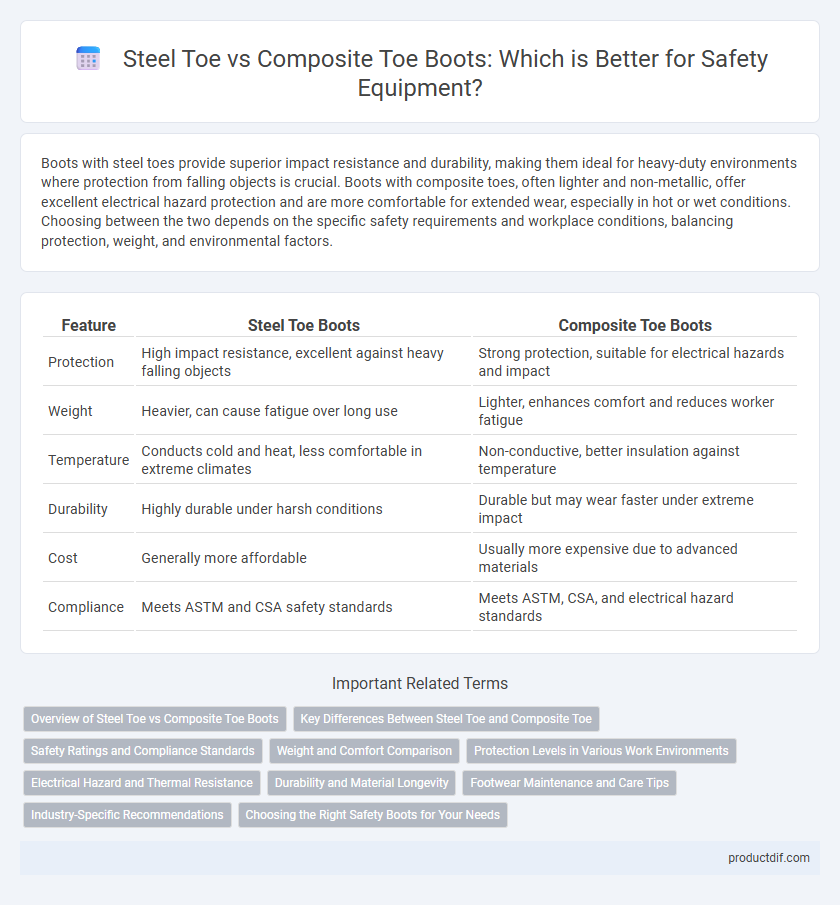

Table of Comparison

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Protection | High impact resistance, excellent against heavy falling objects | Strong protection, suitable for electrical hazards and impact |

| Weight | Heavier, can cause fatigue over long use | Lighter, enhances comfort and reduces worker fatigue |

| Temperature | Conducts cold and heat, less comfortable in extreme climates | Non-conductive, better insulation against temperature |

| Durability | Highly durable under harsh conditions | Durable but may wear faster under extreme impact |

| Cost | Generally more affordable | Usually more expensive due to advanced materials |

| Compliance | Meets ASTM and CSA safety standards | Meets ASTM, CSA, and electrical hazard standards |

Overview of Steel Toe vs Composite Toe Boots

Steel toe boots feature a reinforced steel cap providing superior impact resistance and durability, making them ideal for heavy-duty industrial environments. Composite toe boots use non-metal materials like Kevlar, plastic, or carbon fiber, offering lightweight protection and non-metallic safety suitable for electrical hazard areas and metal detector zones. Both types meet safety standards such as ASTM F2413 but differ in weight, insulation, and conductivity, influencing their application in various workplace settings.

Key Differences Between Steel Toe and Composite Toe

Steel toe boots provide superior impact resistance due to their metal reinforcement, making them ideal for heavy industrial environments with high risk of falling objects. Composite toe boots, made from materials such as Kevlar, carbon fiber, or plastic, offer lighter weight and non-metallic properties, which enhance comfort and are often preferred in security-sensitive areas where metal detection is a concern. Both types meet ASTM safety standards, but steel toes excel in durability and protection, while composite toes excel in weight reduction and electrical hazard insulation.

Safety Ratings and Compliance Standards

Boots with steel toe caps typically meet ASTM F2413-18 safety standards, offering high impact and compression protection suitable for heavy industrial environments. Composite toe boots also comply with ASTM F2413-18 but provide lightweight protection and non-metallic benefits, such as insulation from electricity and heat conductivity. Both types satisfy OSHA requirements, but selection depends on the specific workplace hazard assessment and compliance with site-specific safety protocols.

Weight and Comfort Comparison

Boots with composite toes are significantly lighter than steel toe boots, reducing fatigue during extended wear and enhancing overall comfort. The composite materials provide better insulation against heat and cold compared to steel, contributing to temperature regulation in various work environments. Workers prioritizing weight and comfort often prefer composite toe boots for their lighter feel and improved ergonomic design without compromising safety.

Protection Levels in Various Work Environments

Steel toe boots offer higher impact resistance suitable for heavy industrial jobs involving significant crush hazards, while composite toe boots provide comparable protection with lighter weight and electrical hazard insulation, ideal for environments requiring non-metallic safety gear. Composite toes excel in workplaces like electrical utilities and airports due to their non-conductive properties, whereas steel toes dominate construction and manufacturing sites demanding maximum impact and compression protection. Selection depends on specific workplace risks, balancing protection levels against weight, insulation needs, and compliance with OSHA and ANSI safety standards.

Electrical Hazard and Thermal Resistance

Boots with steel toes provide excellent impact protection but conduct electricity, posing risks in environments with electrical hazards, whereas composite toe boots offer non-conductive properties ideal for electrical safety. Composite toes also typically provide better thermal resistance, making them suitable for extreme temperature conditions. Choosing between steel and composite toe boots depends on the specific safety requirements, especially regarding electrical hazard exposure and thermal insulation needs.

Durability and Material Longevity

Boots with steel toes offer exceptional durability and resistance to impact, maintaining structural integrity even under harsh conditions, making them ideal for heavy-duty industrial use. Composite toe boots, made from materials like Kevlar, carbon fiber, or plastic, provide comparable protection with enhanced corrosion resistance and lighter weight, which can improve wear longevity in environments prone to moisture or chemicals. While steel toes may be more prone to rust over time, composite toes generally uphold material longevity better in wet or corrosive settings, extending the boot's overall service life.

Footwear Maintenance and Care Tips

Steel toe boots require regular inspection for dents or cracks in the steel cap, while composite toe boots need checks for cracks or wear in the non-metallic cap to ensure maximum protection. Both types demand cleaning with mild soap and water, drying away from direct heat, and conditioning leather uppers to maintain flexibility and prevent cracking. Proper storage in a cool, dry place extends lifespan and performance, with insoles replaced periodically to preserve comfort and support.

Industry-Specific Recommendations

Steel toe boots are highly recommended in heavy industries like construction, manufacturing, and mining due to their superior protection against impact and compression hazards. Composite toe boots are preferred in electrical and chemical industries where non-conductive and lightweight safety footwear is essential for reducing fatigue and providing insulation. Choosing boots based on industry-specific safety standards and workplace risks ensures optimal foot protection and compliance with OSHA regulations.

Choosing the Right Safety Boots for Your Needs

Steel toe boots offer superior impact resistance and are ideal for heavy-duty industrial environments with high risk of falling objects, while composite toe boots provide lighter weight and better electrical hazard protection, suitable for electricians or workers in environments sensitive to metal detectors. Selecting the right safety boots depends on workplace hazards, comfort preferences, and specific safety requirements such as weight restrictions, conductivity, and thermal insulation. Prioritize boots meeting ASTM F2413 standards for toe protection to ensure compliance and optimal safety.

Boots with steel toe vs Boots with composite toe Infographic

productdif.com

productdif.com