Hard hats provide superior impact protection with a rigid outer shell designed to withstand heavy falling objects, making them ideal for high-risk environments like construction sites. Bump caps offer lighter protection against minor bumps and scrapes and are more comfortable for extended wear in low-impact settings. Choosing between hard hats and bump caps depends on the specific safety requirements and hazards present in the workplace.

Table of Comparison

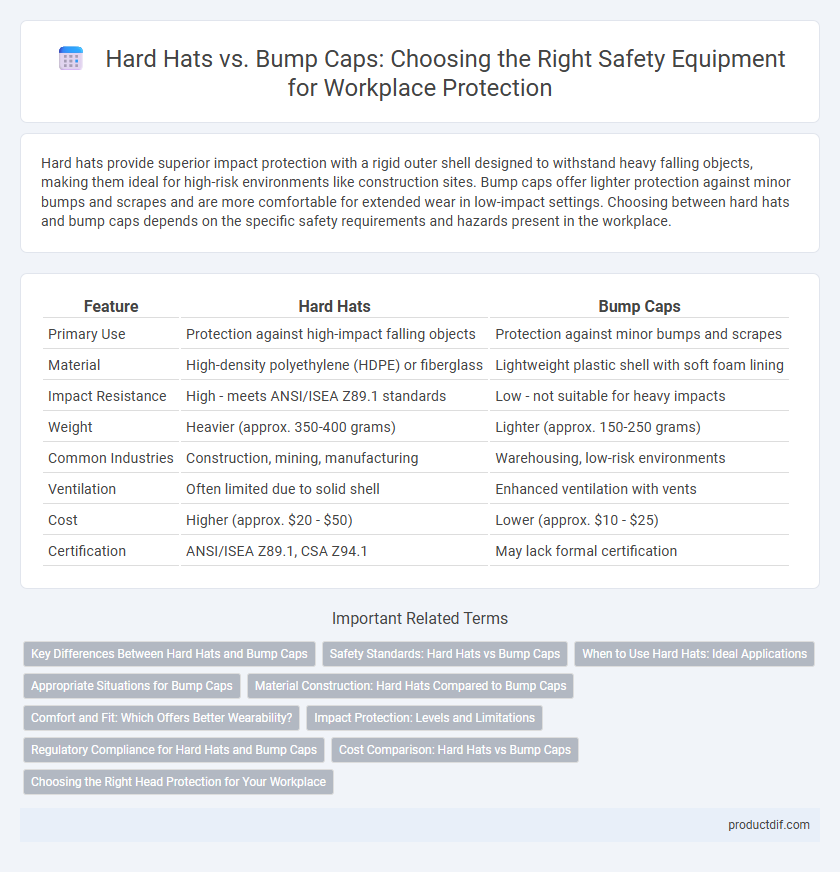

| Feature | Hard Hats | Bump Caps |

|---|---|---|

| Primary Use | Protection against high-impact falling objects | Protection against minor bumps and scrapes |

| Material | High-density polyethylene (HDPE) or fiberglass | Lightweight plastic shell with soft foam lining |

| Impact Resistance | High - meets ANSI/ISEA Z89.1 standards | Low - not suitable for heavy impacts |

| Weight | Heavier (approx. 350-400 grams) | Lighter (approx. 150-250 grams) |

| Common Industries | Construction, mining, manufacturing | Warehousing, low-risk environments |

| Ventilation | Often limited due to solid shell | Enhanced ventilation with vents |

| Cost | Higher (approx. $20 - $50) | Lower (approx. $10 - $25) |

| Certification | ANSI/ISEA Z89.1, CSA Z94.1 | May lack formal certification |

Key Differences Between Hard Hats and Bump Caps

Hard hats provide comprehensive head protection against falling objects, electrical hazards, and impact forces, meeting strict safety standards like ANSI/ISEA Z89.1. Bump caps are designed primarily to protect against minor bumps and scrapes in low-risk environments but lack the robust impact resistance and electrical insulation of hard hats. The key differences include construction materials, certification levels, and intended use cases, with hard hats being mandatory in high-risk industrial settings while bump caps suit confined spaces with limited risk of falling debris.

Safety Standards: Hard Hats vs Bump Caps

Hard hats comply with rigorous safety standards such as ANSI/ISEA Z89.1 and EN 397, designed to protect against high-impact hazards and electrical shock. Bump caps meet lower safety certifications like EN 812, intended primarily for protection against minor bumps and scrapes in low-risk environments. Choosing between hard hats and bump caps depends on the specific workplace hazards and the level of protection required by industry regulations.

When to Use Hard Hats: Ideal Applications

Hard hats are essential in construction sites, industrial environments, and areas with potential falling objects or electrical hazards, providing superior impact and penetration resistance compared to bump caps. Their rigid shell and suspension system ensure maximum protection against high-impact collisions and electrical shocks, making them ideal for heavy machinery operation, scaffolding work, and mining activities. OSHA standards mandate hard hats in situations where head injury risks are significant, ensuring compliance and safety in hazardous work zones.

Appropriate Situations for Bump Caps

Bump caps are designed for low-impact protection in environments where head injuries from minor bumps are possible, such as warehouses, maintenance areas, and indoor construction sites. Unlike hard hats, bump caps are lightweight and ventilated, making them ideal for workers who need comfort during long shifts but do not face risks from falling objects or high-impact hazards. Using bump caps in these appropriate situations helps ensure compliance with safety standards while providing practical head protection.

Material Construction: Hard Hats Compared to Bump Caps

Hard hats are typically made from high-density polyethylene (HDPE) or fiberglass, providing superior impact resistance and durability essential for construction and industrial environments. Bump caps use lighter materials like low-density polyethylene or injection-molded plastics, designed mainly for protection against minor bumps and scrapes rather than heavy impacts. The thicker shell and suspension system of hard hats offer enhanced shock absorption and penetration resistance compared to the minimal padding found in bump caps.

Comfort and Fit: Which Offers Better Wearability?

Hard hats provide superior protection with adjustable suspension systems that enhance comfort for extended wear, especially in high-impact environments. Bump caps, designed for lighter protection, are lighter and often feature flexible fits, offering increased breathability and comfort for less hazardous tasks. Choosing between the two depends on balancing protection needs with comfort preferences, where hard hats excel in safety but bump caps may offer better everyday wearability in low-risk settings.

Impact Protection: Levels and Limitations

Hard hats provide superior impact protection compared to bump caps by meeting stringent safety standards such as ANSI/ISEA Z89.1 and EN 397, designed to withstand high-impact forces and penetration hazards in construction and industrial environments. Bump caps offer limited protection primarily against minor bumps and scrapes, lacking the robust impact resistance necessary for heavy-duty tasks. Choosing the correct head protection depends on hazard assessment, ensuring compliance with workplace safety regulations and optimal injury prevention.

Regulatory Compliance for Hard Hats and Bump Caps

Hard hats meet stringent regulatory standards such as ANSI/ISEA Z89.1 and EN 397, ensuring impact protection and electrical insulation in hazardous work environments. Bump caps offer limited protection and are typically not compliant with these rigorous regulations, making them unsuitable for high-risk industries requiring certified safety gear. Employers must prioritize hard hats over bump caps to maintain compliance with OSHA and international safety guidelines.

Cost Comparison: Hard Hats vs Bump Caps

Hard hats generally cost between $20 and $60, offering robust protection against falling objects and electrical hazards, while bump caps range from $10 to $30, providing basic head protection primarily against minor bumps and scrapes. Companies often choose bump caps for low-risk environments due to their affordability, but hard hats deliver superior impact resistance and compliance with stricter safety standards like ANSI/ISEA Z89.1. Investing in hard hats ensures enhanced worker safety and potential insurance savings despite the higher initial cost.

Choosing the Right Head Protection for Your Workplace

Selecting the appropriate head protection involves understanding the distinctions between hard hats and bump caps; hard hats provide robust defense against heavy falling objects and electrical hazards, meeting strict ANSI and OSHA standards. Bump caps offer lightweight protection against minor bumps and scrapes, ideal for low-impact environments where heavy-duty protection is unnecessary. Assess workplace hazards, regulatory requirements, and comfort preferences to ensure optimal safety compliance and employee well-being.

Hard hats vs Bump caps Infographic

productdif.com

productdif.com