EN 388 and EN 420 are key standards for safety equipment, with EN 388 specifically addressing protective gloves against mechanical risks such as abrasion, cuts, and punctures, while EN 420 sets the general requirements and testing methods for glove design, construction, and comfort. EN 388 focuses on performance levels to ensure durability and protection in hazardous environments, whereas EN 420 ensures gloves meet ergonomic and safety criteria for everyday use. Choosing safety equipment compliant with both standards guarantees comprehensive protection and usability for pet handlers and professionals.

Table of Comparison

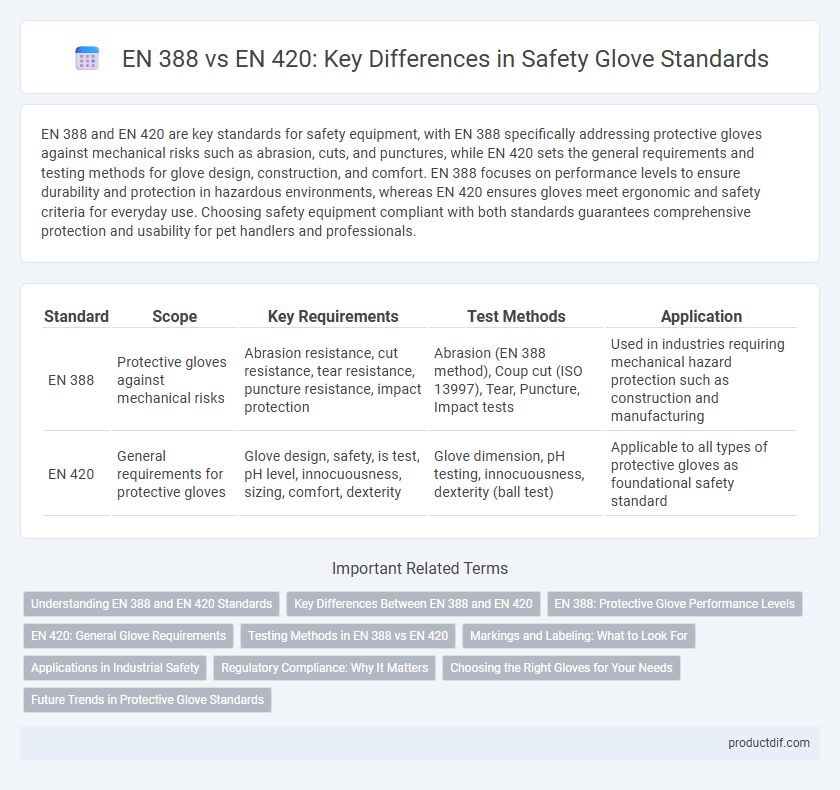

| Standard | Scope | Key Requirements | Test Methods | Application |

|---|---|---|---|---|

| EN 388 | Protective gloves against mechanical risks | Abrasion resistance, cut resistance, tear resistance, puncture resistance, impact protection | Abrasion (EN 388 method), Coup cut (ISO 13997), Tear, Puncture, Impact tests | Used in industries requiring mechanical hazard protection such as construction and manufacturing |

| EN 420 | General requirements for protective gloves | Glove design, safety, is test, pH level, innocuousness, sizing, comfort, dexterity | Glove dimension, pH testing, innocuousness, dexterity (ball test) | Applicable to all types of protective gloves as foundational safety standard |

Understanding EN 388 and EN 420 Standards

EN 388 specifies performance requirements for protective gloves against mechanical risks, including abrasion, cut, tear, and puncture resistance, making it essential for evaluating gloves' durability and safety in industrial settings. EN 420 outlines general requirements for glove construction, safety, comfort, and dexterity, ensuring gloves meet fundamental protective and ergonomic standards before specialized testing. Understanding both standards helps select appropriate safety equipment that balances mechanical protection and wearer comfort for optimal performance.

Key Differences Between EN 388 and EN 420

EN 388 specifies performance requirements for protective gloves against mechanical risks, including abrasion, cut, tear, and puncture resistance, while EN 420 establishes general requirements and testing for glove safety and ergonomics, such as design, sizing, and harmlessness. EN 388 focuses exclusively on gloves used in industrial applications requiring high mechanical protection, whereas EN 420 serves as the foundational standard applicable to all protective gloves, ensuring basic safety and comfort criteria are met. The key differentiation lies in EN 388's detailed mechanical performance metrics compared to EN 420's broad safety and usability provisions.

EN 388: Protective Glove Performance Levels

EN 388 specifies performance levels for protective gloves against mechanical risks, including abrasion, cut, tear, and puncture resistance, essential for workplace safety in industries like construction and manufacturing. This standard uses numerical ratings to quantify glove durability and protection, facilitating informed decisions for hand safety. EN 420, in contrast, defines general requirements for glove design and hygiene but does not include specific performance metrics like EN 388.

EN 420: General Glove Requirements

EN 420 sets the general requirements for protective gloves, establishing essential criteria such as glove design, comfort, dexterity, and harmlessness to the user, forming the foundation for all glove certifications. Unlike EN 388, which specifically tests gloves for mechanical risks including abrasion, cut, tear, and puncture resistance, EN 420 ensures overall safety standards and performance of glove materials and construction. Compliance with EN 420 is mandatory before gloves undergo specialized testing under EN 388, guaranteeing broad user protection and quality.

Testing Methods in EN 388 vs EN 420

EN 388 testing methods focus specifically on evaluating mechanical risks such as abrasion, cut, tear, and puncture resistance to ensure gloves provide adequate protection in industrial environments. EN 420 serves as a general requirement standard establishing the safety, ergonomics, and performance criteria for protective gloves, including basic testing for glove construction and harmlessness. The comparative emphasis identifies EN 388 as specialized for mechanical protection assessment, whereas EN 420 provides foundational safety and quality benchmarks for all protective gloves.

Markings and Labeling: What to Look For

EN 388 and EN 420 standards both mandate specific markings and labeling on safety gloves to ensure proper identification and compliance; EN 388 focuses on mechanical risks and requires a pictogram with performance levels for abrasion, cut, tear, and puncture resistance. EN 420 establishes general requirements for glove design and safety, including size, manufacturer information, and CE marking, ensuring the glove's overall compliance with EU personal protective equipment regulations. Checking for these labels and pictograms ensures users select gloves that meet the necessary protection standards for their specific workplace hazards.

Applications in Industrial Safety

EN 388 specifies performance requirements for protective gloves against mechanical risks, crucial in industries such as construction, manufacturing, and automotive assembly where cut, abrasion, and puncture resistance are vital. EN 420 establishes general requirements for glove design, sizing, and comfort, serving as the baseline standard for all protective gloves used in industrial safety applications. Understanding the distinctions ensures proper glove selection to optimize worker protection and compliance with safety regulations.

Regulatory Compliance: Why It Matters

EN 388 specifies performance requirements for protective gloves against mechanical risks, ensuring compliance with safety standards for impact, abrasion, and cut resistance. EN 420 outlines general glove safety and construction requirements, including sizing, comfort, and absence of harmful substances, which are essential for regulatory approval across industries. Adhering to both EN 388 and EN 420 ensures comprehensive regulatory compliance, reducing liability and enhancing worker safety in hazardous environments.

Choosing the Right Gloves for Your Needs

EN 388 specifies performance requirements for protective gloves against mechanical risks, including abrasion, cut, tear, and puncture resistance, making it essential when selecting gloves for industrial and construction tasks. EN 420 defines general requirements for glove design, comfort, and safety, ensuring proper fit, dexterity, and absence of harmful substances, which complements EN 388 standards. Prioritize gloves certified under both EN 388 and EN 420 to achieve optimal protection and ergonomic performance tailored to specific workplace hazards.

Future Trends in Protective Glove Standards

Future trends in protective glove standards emphasize enhanced durability and cut resistance, with EN 388 evolving to include more rigorous testing methods for abrasion, cut, tear, and puncture resistance. EN 420 remains the foundational general requirement standard, ensuring gloves meet basic safety, comfort, and dexterity criteria, while future updates aim to integrate smart technologies and sustainability metrics. Innovations in materials and digital certification processes are expected to drive the convergence of standards, promoting higher safety performance and user-centric designs in protective gloves.

EN 388 vs EN 420 Infographic

productdif.com

productdif.com