Safety Data Sheets (SDS) provide comprehensive information about the properties, handling, and emergency measures for pet safety equipment chemicals, superseding the older Material Safety Data Sheets (MSDS). SDS use a standardized 16-section format to ensure consistent communication of hazards, improving understanding and regulatory compliance. Pet owners and professionals rely on SDS to make informed decisions regarding safe use, storage, and disposal of pet-related products containing hazardous substances.

Table of Comparison

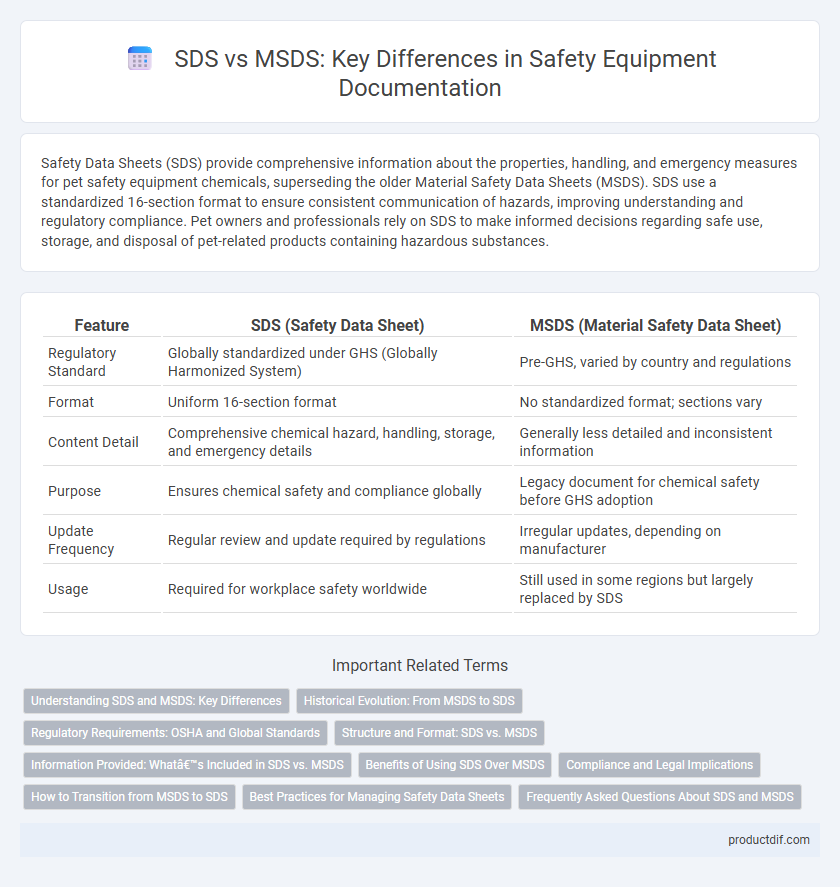

| Feature | SDS (Safety Data Sheet) | MSDS (Material Safety Data Sheet) |

|---|---|---|

| Regulatory Standard | Globally standardized under GHS (Globally Harmonized System) | Pre-GHS, varied by country and regulations |

| Format | Uniform 16-section format | No standardized format; sections vary |

| Content Detail | Comprehensive chemical hazard, handling, storage, and emergency details | Generally less detailed and inconsistent information |

| Purpose | Ensures chemical safety and compliance globally | Legacy document for chemical safety before GHS adoption |

| Update Frequency | Regular review and update required by regulations | Irregular updates, depending on manufacturer |

| Usage | Required for workplace safety worldwide | Still used in some regions but largely replaced by SDS |

Understanding SDS and MSDS: Key Differences

Safety Data Sheets (SDS) and Material Safety Data Sheets (MSDS) provide critical information on chemical hazards, but SDS follows the Globally Harmonized System (GHS) format with 16 standardized sections, enhancing clarity and consistency. MSDS formats vary by country and supplier, often leading to inconsistent presentation and potential gaps in hazard communication. Understanding these differences ensures proper compliance and improves workplace safety by providing clear hazard identification, handling precautions, and emergency measures.

Historical Evolution: From MSDS to SDS

The transition from MSDS (Material Safety Data Sheet) to SDS (Safety Data Sheet) marks a significant improvement in chemical safety communication, driven by the Globally Harmonized System (GHS) adoption. Introduced in 2012, SDS offers a standardized 16-section format that enhances clarity and consistency across international borders, replacing the often variable MSDS formats. This evolution facilitates better hazard identification, risk management, and compliance for industries handling hazardous substances.

Regulatory Requirements: OSHA and Global Standards

OSHA requires Safety Data Sheets (SDS) to comply with the Globally Harmonized System (GHS) for hazardous chemical communication, replacing the older Material Safety Data Sheets (MSDS). SDS must include standardized sections such as hazard identification, composition, and exposure controls, ensuring consistency across global suppliers and manufacturers. Compliance with OSHA and international standards like REACH and WHMIS ensures accurate hazard communication and legal adherence worldwide.

Structure and Format: SDS vs. MSDS

The Safety Data Sheet (SDS) features a standardized 16-section format mandated by the Globally Harmonized System (GHS), enhancing clarity and consistency worldwide. In contrast, the older Material Safety Data Sheet (MSDS) lacks uniform structure, resulting in variable formats depending on the manufacturer or region. This standardized SDS format improves hazard communication and regulatory compliance across industries.

Information Provided: What’s Included in SDS vs. MSDS

Safety Data Sheets (SDS) provide detailed information on chemical properties, hazards, handling precautions, and emergency measures, complying with the Globally Harmonized System (GHS) standards. Material Safety Data Sheets (MSDS) may vary in format and content, often lacking standardized sections such as toxicological information, first-aid measures, and exposure controls. SDS ensures comprehensive, consistent data for safe chemical management, including physical data, stability, reactivity, and regulatory information, which MSDS formats might omit or present inconsistently.

Benefits of Using SDS Over MSDS

Safety Data Sheets (SDS) provide standardized, consistent information across all countries following the Globally Harmonized System (GHS), improving clarity and compliance in handling hazardous materials. Unlike Material Safety Data Sheets (MSDS), SDS formats include 16 detailed sections that enhance risk assessment and emergency response effectiveness. Using SDS reduces confusion and increases workplace safety by delivering up-to-date, easily accessible, and internationally recognized chemical safety information.

Compliance and Legal Implications

Safety Data Sheets (SDS) comply with the Globally Harmonized System (GHS) standards, ensuring consistent hazard communication worldwide, while Material Safety Data Sheets (MSDS) follow older regulations that vary by country. Regulatory bodies like OSHA require employers to maintain updated SDS documents for legal compliance, failure of which can lead to fines and workplace safety violations. Transitioning to SDS from MSDS minimizes legal risks and aligns safety practices with international regulatory frameworks.

How to Transition from MSDS to SDS

Transitioning from MSDS to SDS requires updating documentation to comply with the Globally Harmonized System (GHS) format, which standardizes hazard communication worldwide. Organizations must train employees on the 16-section SDS layout, emphasizing clearer hazard identification, composition, and handling instructions compared to older MSDS formats. Implementing software solutions and conducting thorough audits ensure all chemical safety data sheets meet current regulatory standards for workplace safety and environmental compliance.

Best Practices for Managing Safety Data Sheets

Safety Data Sheets (SDS) have replaced Material Safety Data Sheets (MSDS) to comply with the Globally Harmonized System (GHS) for hazardous communication, standardizing chemical safety information worldwide. Best practices for managing SDS include maintaining an up-to-date digital repository accessible to all employees, ensuring proper labeling and training on chemical hazards. Regular audits and automated alerts for reviewing and updating SDS help organizations stay compliant and enhance workplace safety.

Frequently Asked Questions About SDS and MSDS

Safety Data Sheets (SDS) and Material Safety Data Sheets (MSDS) both provide critical information on chemical substances, but SDS follows the Globally Harmonized System (GHS) format, ensuring standardized data on hazards, handling, and emergency measures. Frequently asked questions about SDS and MSDS often address the structural differences, legal requirements, and the transition timeline from MSDS to SDS in workplaces worldwide. Understanding these distinctions is essential for compliance, proper safety equipment use, and effective risk management in handling hazardous materials.

SDS vs MSDS Infographic

productdif.com

productdif.com