Emergency eyewash stations provide immediate flushing to cleanse hazardous substances from the eyes, minimizing injury during chemical exposure. Emergency showers are designed for rapid full-body decontamination, effectively rinsing off chemicals that have come into contact with skin or clothing. Choosing between these safety equipment options depends on the nature of the exposure and the required decontamination area.

Table of Comparison

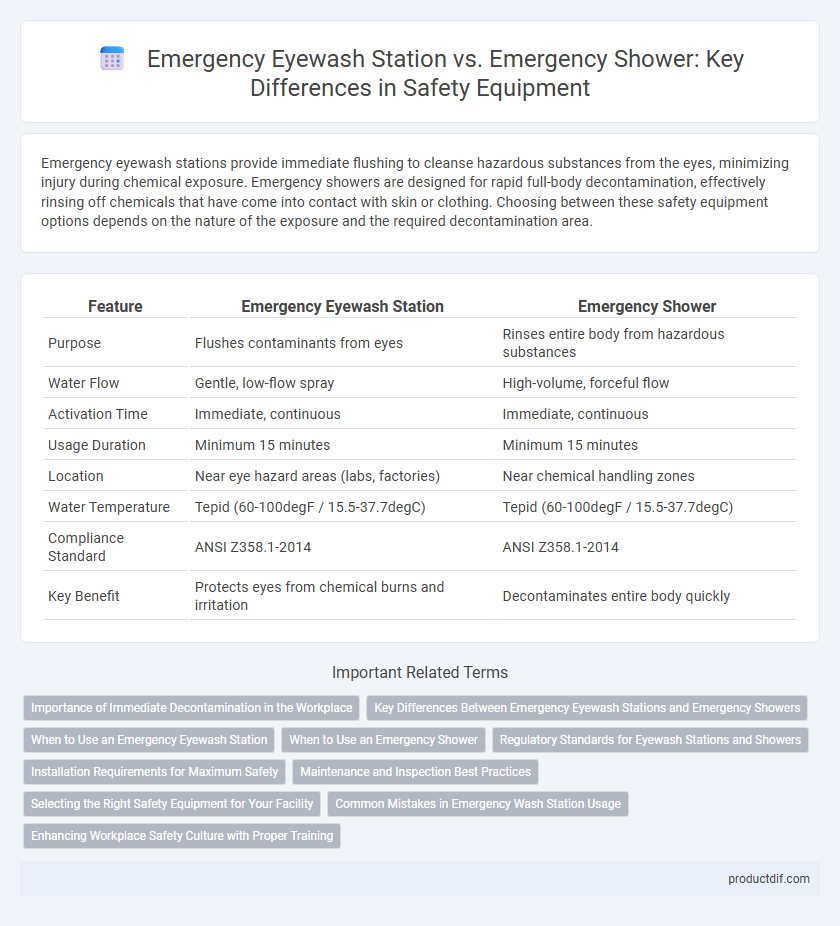

| Feature | Emergency Eyewash Station | Emergency Shower |

|---|---|---|

| Purpose | Flushes contaminants from eyes | Rinses entire body from hazardous substances |

| Water Flow | Gentle, low-flow spray | High-volume, forceful flow |

| Activation Time | Immediate, continuous | Immediate, continuous |

| Usage Duration | Minimum 15 minutes | Minimum 15 minutes |

| Location | Near eye hazard areas (labs, factories) | Near chemical handling zones |

| Water Temperature | Tepid (60-100degF / 15.5-37.7degC) | Tepid (60-100degF / 15.5-37.7degC) |

| Compliance Standard | ANSI Z358.1-2014 | ANSI Z358.1-2014 |

| Key Benefit | Protects eyes from chemical burns and irritation | Decontaminates entire body quickly |

Importance of Immediate Decontamination in the Workplace

Emergency eyewash stations and emergency showers provide crucial immediate decontamination by rapidly flushing hazardous substances from the eyes and body, minimizing chemical injury severity. Prompt use of these safety equipment options reduces exposure time to harmful chemicals, preventing long-term tissue damage and improving overall workplace safety. Ensuring accessible and properly maintained emergency eyewash stations and showers is vital for compliance with OSHA regulations and effective incident response.

Key Differences Between Emergency Eyewash Stations and Emergency Showers

Emergency eyewash stations deliver a controlled flow of water specifically designed to flush hazardous substances from the eyes, providing immediate decontamination, whereas emergency showers offer a full-body rinse to remove larger chemical spills or contaminants from clothing and skin. Eyewash stations are typically equipped with gentle, aerated water streams to prevent eye damage, while emergency showers produce a high-volume water flow to quickly dilute and remove harmful substances. Placement and activation methods also differ, with eyewash stations often located near eye-level for rapid access and showers requiring a pull handle or lever to activate a sustained water flow.

When to Use an Emergency Eyewash Station

Use an emergency eyewash station immediately when hazardous substances such as chemicals, acids, or debris come into direct contact with the eyes to prevent severe injury or blindness. Emergency eyewash stations provide a continuous flow of water to flush out contaminants quickly and are designed for rapid, targeted eye decontamination. Always position eyewash stations within a 10-second reach from high-risk areas to ensure prompt treatment of eye exposure emergencies.

When to Use an Emergency Shower

Use an emergency shower when hazardous chemicals have been spilled or splashed over large areas of the body, posing immediate risk to skin and clothing. Emergency showers provide rapid dilution and removal of contaminants, minimizing chemical burns and absorption. These showers are essential in laboratories, manufacturing plants, and places handling corrosive substances to quickly mitigate exposure.

Regulatory Standards for Eyewash Stations and Showers

Emergency eyewash stations and showers must comply with ANSI Z358.1 standards, which specify requirements for installation, maintenance, and performance to ensure rapid and effective decontamination. OSHA mandates accessible and functional eyewash and shower units in workplaces with hazardous chemical exposure to prevent severe injuries. Regular testing and flushing of these safety equipment units are essential to meet regulatory compliance and ensure immediate availability during emergencies.

Installation Requirements for Maximum Safety

Emergency eyewash stations must be installed within 10 seconds or approximately 55 feet from the hazard to ensure immediate access, while emergency showers require a similar proximity for effective decontamination. Both require accessible pathways free of obstructions, with ANSI Z358.1 standards specifying a minimum flow rate of 0.4 gallons per minute for eyewash stations and 20 gallons per minute for showers. Proper signage, lighting, and temperature-controlled water delivery are critical installation factors to maximize safety during chemical exposure incidents.

Maintenance and Inspection Best Practices

Routine maintenance of emergency eyewash stations includes flushing the system weekly to prevent sediment buildup and verifying water flow meets ANSI Z358.1 standards; inspection should check for unobstructed access and clear signage. Emergency showers require monthly activation to ensure adequate water temperature and pressure, alongside visual inspections for corrosion or leaks in the piping and valve components. Both stations must have detailed maintenance logs and staff training updates to ensure compliance and functionality during emergencies.

Selecting the Right Safety Equipment for Your Facility

Emergency eyewash stations provide immediate flushing of contaminants from the eyes and are essential in environments with chemical exposure or particulates, ensuring rapid decontamination within seconds. Emergency showers are designed to rinse off hazardous substances from the entire body, especially important in facilities handling large volumes of corrosive liquids or toxic chemicals. Selecting the right safety equipment depends on the specific hazards present, compliance with OSHA and ANSI standards, and the proximity of the equipment to potential exposure areas for effective emergency response.

Common Mistakes in Emergency Wash Station Usage

Common mistakes in emergency eyewash station usage include insufficient activation time and failure to remove contact lenses promptly, reducing effectiveness in flushing contaminants. Users often neglect to hold eyes open or direct the spray correctly, leading to incomplete rinsing and potential eye damage. In contrast, emergency shower misuse typically involves inadequate shower duration or neglecting to remove contaminated clothing, which impairs thorough decontamination.

Enhancing Workplace Safety Culture with Proper Training

Proper training on the use of emergency eyewash stations and emergency showers is crucial for enhancing workplace safety culture by ensuring employees respond swiftly and correctly to chemical exposures. Emergency eyewash stations provide immediate flushing of hazardous substances from the eyes, while emergency showers offer full-body decontamination for larger spills. Regular drills and clear instructional signage increase employee confidence, reduce injury severity, and promote a proactive approach to workplace safety compliance.

Emergency eyewash station vs Emergency shower Infographic

productdif.com

productdif.com