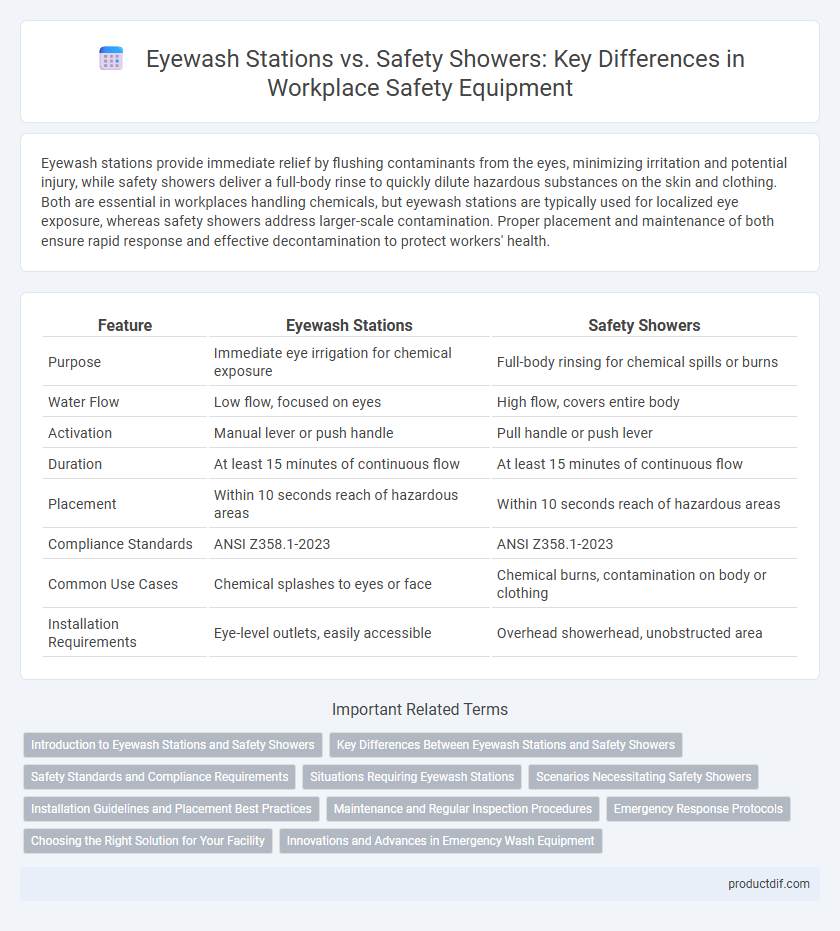

Eyewash stations provide immediate relief by flushing contaminants from the eyes, minimizing irritation and potential injury, while safety showers deliver a full-body rinse to quickly dilute hazardous substances on the skin and clothing. Both are essential in workplaces handling chemicals, but eyewash stations are typically used for localized eye exposure, whereas safety showers address larger-scale contamination. Proper placement and maintenance of both ensure rapid response and effective decontamination to protect workers' health.

Table of Comparison

| Feature | Eyewash Stations | Safety Showers |

|---|---|---|

| Purpose | Immediate eye irrigation for chemical exposure | Full-body rinsing for chemical spills or burns |

| Water Flow | Low flow, focused on eyes | High flow, covers entire body |

| Activation | Manual lever or push handle | Pull handle or push lever |

| Duration | At least 15 minutes of continuous flow | At least 15 minutes of continuous flow |

| Placement | Within 10 seconds reach of hazardous areas | Within 10 seconds reach of hazardous areas |

| Compliance Standards | ANSI Z358.1-2023 | ANSI Z358.1-2023 |

| Common Use Cases | Chemical splashes to eyes or face | Chemical burns, contamination on body or clothing |

| Installation Requirements | Eye-level outlets, easily accessible | Overhead showerhead, unobstructed area |

Introduction to Eyewash Stations and Safety Showers

Eyewash stations and safety showers are essential safety equipment designed to provide immediate decontamination for chemical splashes or exposure in workplaces. Eyewash stations deliver a controlled flow of water to flush hazardous substances from the eyes, reducing the risk of injury and preserving vision. Safety showers emit a large volume of water rapidly to rinse chemicals from the entire body, mitigating contamination and preventing sustained chemical burns or damage.

Key Differences Between Eyewash Stations and Safety Showers

Eyewash stations provide immediate flushing of the eyes to remove hazardous substances, while safety showers deliver a full-body rinse to wash off chemical contaminants quickly. Eyewash stations typically feature two nozzles that supply a gentle flow of water for at least 15 minutes, meeting ANSI/ISEA Z358.1 standards, whereas safety showers require a larger volume of water to cover the entire body. Placement of eyewash stations is crucial near eye-level hazards, while safety showers are installed where full-body exposure risks exist, ensuring rapid decontamination in emergency situations.

Safety Standards and Compliance Requirements

Eyewash stations and safety showers must comply with ANSI Z358.1 standards to ensure effective emergency decontamination. Safety showers require a flow rate of at least 20 gallons per minute for 15 minutes, while eyewash stations mandate 0.4 gallons per minute for the same duration. Both devices must be installed within 10 seconds of the hazard and regularly inspected to meet OSHA and ANSI regulatory compliance.

Situations Requiring Eyewash Stations

Situations requiring eyewash stations include exposure to hazardous chemicals, corrosive substances, or debris that can cause eye injuries or irritation in laboratories, manufacturing plants, and construction sites. Eyewash stations provide immediate decontamination to minimize damage and prevent long-term vision impairment. OSHA regulations mandate accessible eyewash stations within 10 seconds of hazardous areas to ensure prompt emergency response.

Scenarios Necessitating Safety Showers

Safety showers are essential in scenarios involving large chemical spills or exposure to hazardous substances on the skin, providing rapid decontamination to prevent chemical burns and systemic toxicity. Unlike eyewash stations designed specifically for flushing the eyes, safety showers cover the entire body, making them critical when corrosive chemicals, flammable liquids, or toxic agents pose a risk of widespread contamination. OSHA and ANSI standards mandate safety showers in laboratories, industrial sites, and workplaces handling dangerous substances to ensure immediate emergency response and minimize injury severity.

Installation Guidelines and Placement Best Practices

Eyewash stations should be installed within 10 seconds or approximately 55 feet from the hazard, with unobstructed access and proper drainage to ensure immediate use during chemical exposure. Safety showers must be positioned in the same proximity, featuring clear signage and adequate lighting for quick identification and activation in emergencies. Both installations require compliance with OSHA and ANSI standards, emphasizing ergonomic placement at eye or head level for eyewash stations and full-body coverage for safety showers to maximize effectiveness.

Maintenance and Regular Inspection Procedures

Eyewash stations require daily activation to ensure proper water flow and contamination-free nozzles, while safety showers demand weekly flushing to prevent sediment buildup and maintain adequate water pressure. Inspection protocols include checking for unobstructed access, proper signage, and functional activation mechanisms, with records maintained for compliance verification. Failure to adhere to these maintenance schedules can compromise emergency response effectiveness and increase the risk of injury during hazardous material exposure.

Emergency Response Protocols

Eyewash stations provide immediate flushing of hazardous substances from the eyes, crucial for minimizing chemical exposure damage during emergency response protocols. Safety showers deliver a full-body rinse to quickly remove contaminants from skin and clothing, essential for mitigating severe chemical burns or spills. Emergency response procedures often prioritize activating eyewash stations within 10 seconds of eye exposure and safety showers for prolonged decontamination lasting at least 15 minutes.

Choosing the Right Solution for Your Facility

Eyewash stations and safety showers serve distinct emergency purposes, with eyewash stations designed for immediate eye rinsing to remove harmful substances, while safety showers provide full-body decontamination in case of chemical exposure. When selecting safety equipment, consider the nature of chemicals handled, potential exposure risks, and regulatory compliance from OSHA and ANSI standards. Proper placement and accessibility of both eyewash stations and safety showers are critical to ensuring rapid response and minimizing injury in hazardous environments.

Innovations and Advances in Emergency Wash Equipment

Innovations in emergency wash equipment have led to enhanced functionality in eyewash stations and safety showers, incorporating features such as hands-free activation, temperature-controlled water delivery, and integrated microbial filtration systems. Advanced sensor technology ensures rapid detection and activation, minimizing response time during chemical exposure incidents. These developments improve user safety by delivering consistent, sterile rinsing solutions, thereby reducing contamination risk and promoting quicker, more effective decontamination processes.

Eyewash stations vs Safety showers Infographic

productdif.com

productdif.com