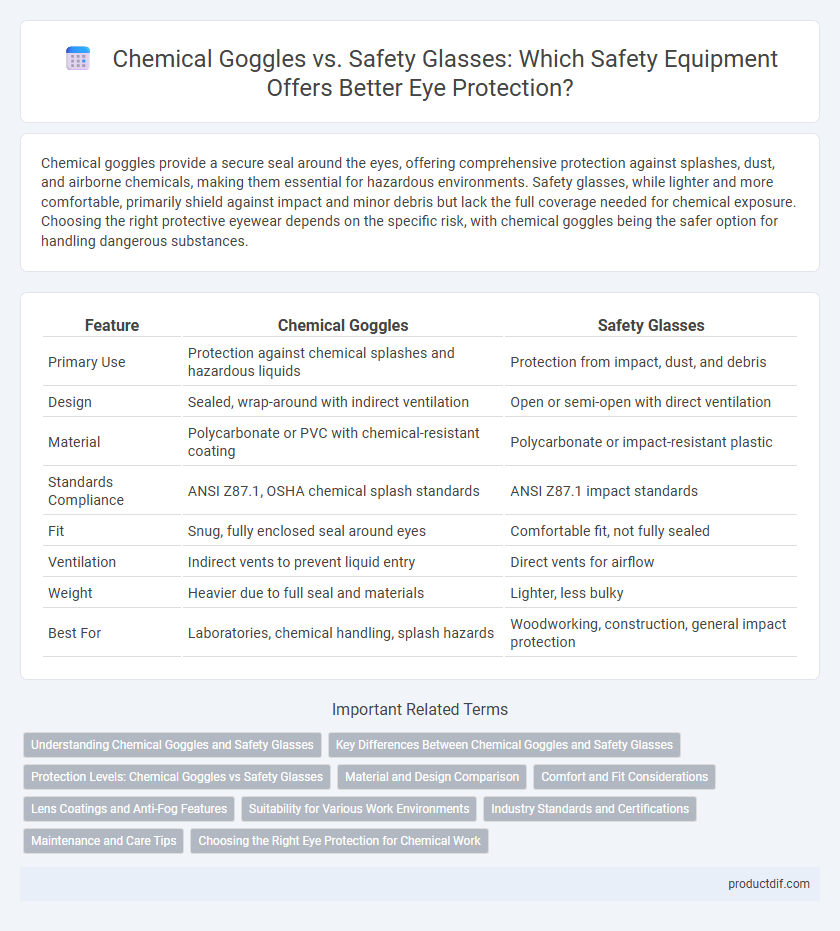

Chemical goggles provide a secure seal around the eyes, offering comprehensive protection against splashes, dust, and airborne chemicals, making them essential for hazardous environments. Safety glasses, while lighter and more comfortable, primarily shield against impact and minor debris but lack the full coverage needed for chemical exposure. Choosing the right protective eyewear depends on the specific risk, with chemical goggles being the safer option for handling dangerous substances.

Table of Comparison

| Feature | Chemical Goggles | Safety Glasses |

|---|---|---|

| Primary Use | Protection against chemical splashes and hazardous liquids | Protection from impact, dust, and debris |

| Design | Sealed, wrap-around with indirect ventilation | Open or semi-open with direct ventilation |

| Material | Polycarbonate or PVC with chemical-resistant coating | Polycarbonate or impact-resistant plastic |

| Standards Compliance | ANSI Z87.1, OSHA chemical splash standards | ANSI Z87.1 impact standards |

| Fit | Snug, fully enclosed seal around eyes | Comfortable fit, not fully sealed |

| Ventilation | Indirect vents to prevent liquid entry | Direct vents for airflow |

| Weight | Heavier due to full seal and materials | Lighter, less bulky |

| Best For | Laboratories, chemical handling, splash hazards | Woodworking, construction, general impact protection |

Understanding Chemical Goggles and Safety Glasses

Chemical goggles provide a sealed barrier around the eyes, offering superior protection against liquid splashes, hazardous fumes, and airborne particles, making them essential for handling corrosive chemicals. Safety glasses feature impact-resistant lenses with side shields, designed primarily to guard against flying debris and minor splashes but lack full enclosure. Choosing between chemical goggles and safety glasses depends on the specific hazards present in the work environment and the level of eye protection required.

Key Differences Between Chemical Goggles and Safety Glasses

Chemical goggles provide a complete seal around the eyes, offering protection from liquid splashes, fumes, and airborne particles, whereas safety glasses typically have open or vented frames that allow airflow but reduce protection against chemical splashes. Chemical goggles are designed with indirect vents or non-vented enclosures to prevent hazardous liquids and vapors from entering, making them suitable for high-risk chemical handling environments, while safety glasses primarily protect against impact and debris. The material used in chemical goggles often includes anti-fog coatings and shatter-resistant lenses, enhancing visibility and durability in chemical-intensive workplaces compared to standard safety glasses.

Protection Levels: Chemical Goggles vs Safety Glasses

Chemical goggles provide a higher level of protection by creating a sealed barrier around the eyes, effectively preventing hazardous liquids, vapors, and fine particles from entering. Safety glasses offer basic impact resistance but lack the full enclosure needed to guard against chemical splashes or airborne contaminants. For environments with exposure to corrosive chemicals or biohazards, chemical goggles are the preferred choice to ensure comprehensive eye safety.

Material and Design Comparison

Chemical goggles are typically made from flexible PVC or polyurethane materials that provide a sealed barrier to protect against chemical splashes, while safety glasses are constructed from impact-resistant polycarbonate lenses designed mainly for physical hazards. The design of chemical goggles includes a snug fit with indirect ventilation to prevent liquid entry, contrasting with the open and lightweight frame of safety glasses, which prioritize comfort and breathability. This material and design distinction makes chemical goggles more effective for handling hazardous chemicals, whereas safety glasses suit environments with flying debris risks.

Comfort and Fit Considerations

Chemical goggles provide a secure seal around the eyes, ensuring maximum protection against chemical splashes, but may feel heavier and less breathable during extended wear compared to safety glasses. Safety glasses offer greater comfort and lighter weight, with adjustable temples and nose pads enhancing fit for prolonged use, though they lack the enclosed design necessary for splash protection. Selecting the appropriate safety equipment requires balancing comfort and fit with the specific hazard risks present in the work environment.

Lens Coatings and Anti-Fog Features

Chemical goggles feature specialized lens coatings such as anti-scratch and anti-fog treatments to maintain clear vision in harsh chemical environments. Safety glasses often incorporate basic anti-fog coatings but typically lack the comprehensive seal and enhanced protection provided by goggle lenses. Choosing chemical goggles with advanced lens coatings ensures better resistance to fogging and chemical splashes, crucial for maintaining visibility and safety in laboratories and industrial settings.

Suitability for Various Work Environments

Chemical goggles provide a higher level of protection against splashes, vapors, and airborne particles, making them suitable for laboratories and environments with hazardous chemical exposure. Safety glasses offer impact resistance and basic eye protection, ideal for construction sites and manufacturing where flying debris is a concern but chemical exposure is minimal. Selecting the appropriate eye protection depends on the specific hazards present in the work environment to ensure compliance with OSHA standards and maximize safety.

Industry Standards and Certifications

Chemical goggles comply with ANSI Z87.1 and OSHA standards, providing a sealed barrier to protect against liquid splashes, fumes, and airborne particles. Safety glasses also meet ANSI Z87.1 certifications but lack the full enclosure, making them suitable for impact protection rather than chemical exposure. Both types typically carry CSA certification in Canada, ensuring compliance with regional industrial safety regulations.

Maintenance and Care Tips

Chemical goggles require regular cleaning with mild soap and water to remove residues and prevent fogging, while safety glasses benefit from anti-scratch and anti-fog coatings for extended clarity. Store both types in a protective case away from direct sunlight to maintain lens integrity and prevent damage. Inspect straps on goggles and frames on glasses frequently to ensure a secure fit and replace any worn or damaged parts promptly.

Choosing the Right Eye Protection for Chemical Work

Chemical goggles provide a sealed fit that protects against liquid splashes, vapors, and airborne particles, making them ideal for handling hazardous chemicals. Safety glasses offer impact resistance and basic splash protection but lack a complete seal, leaving gaps that can allow harmful substances to reach the eyes. Selecting appropriate eye protection depends on the specific chemical hazards, ensuring compliance with OSHA standards and ANSI Z87.1 requirements for maximum safety.

Chemical goggles vs Safety glasses Infographic

productdif.com

productdif.com