UART provides a simple, point-to-point serial communication protocol ideal for short-distance data exchange with minimal hardware requirements, typically used in microcontroller interfaces and debugging. CAN, on the other hand, supports robust multi-node networking with error detection and fault confinement, making it suitable for automotive and industrial applications requiring high reliability and real-time data transmission. While UART operates asynchronously with variable baud rates, CAN uses a priority-based message arbitration to ensure efficient communication among multiple devices on the same bus.

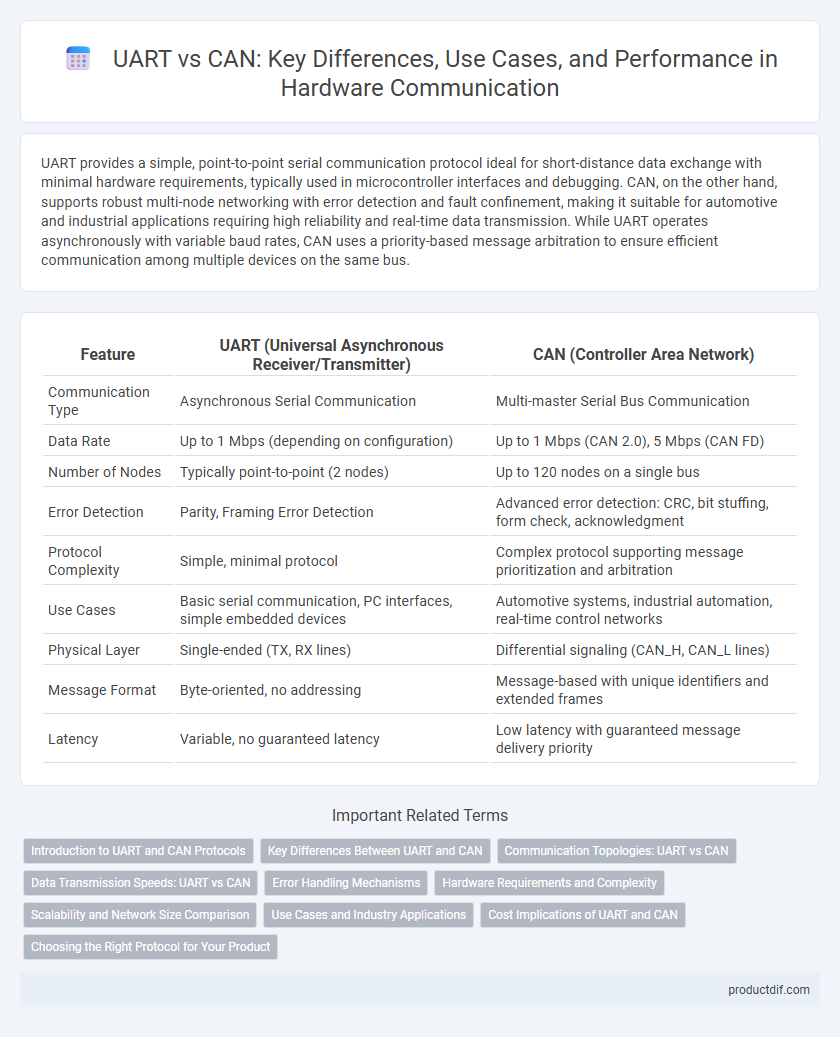

Table of Comparison

| Feature | UART (Universal Asynchronous Receiver/Transmitter) | CAN (Controller Area Network) |

|---|---|---|

| Communication Type | Asynchronous Serial Communication | Multi-master Serial Bus Communication |

| Data Rate | Up to 1 Mbps (depending on configuration) | Up to 1 Mbps (CAN 2.0), 5 Mbps (CAN FD) |

| Number of Nodes | Typically point-to-point (2 nodes) | Up to 120 nodes on a single bus |

| Error Detection | Parity, Framing Error Detection | Advanced error detection: CRC, bit stuffing, form check, acknowledgment |

| Protocol Complexity | Simple, minimal protocol | Complex protocol supporting message prioritization and arbitration |

| Use Cases | Basic serial communication, PC interfaces, simple embedded devices | Automotive systems, industrial automation, real-time control networks |

| Physical Layer | Single-ended (TX, RX lines) | Differential signaling (CAN_H, CAN_L lines) |

| Message Format | Byte-oriented, no addressing | Message-based with unique identifiers and extended frames |

| Latency | Variable, no guaranteed latency | Low latency with guaranteed message delivery priority |

Introduction to UART and CAN Protocols

UART (Universal Asynchronous Receiver Transmitter) is a hardware communication protocol that facilitates serial data transmission without the need for a clock signal, making it ideal for short-distance, low-speed data exchange between microcontrollers and peripheral devices. CAN (Controller Area Network) is a robust vehicle bus standard designed for reliable communication in automotive and industrial environments, allowing multiple microcontrollers to communicate on a shared, differential two-wire bus with error detection and fault confinement features. Both UART and CAN operate at different layers of the communication hierarchy, with UART being simpler and UART suitable for basic serial communication, whereas CAN provides complex network management suitable for real-time control systems.

Key Differences Between UART and CAN

UART (Universal Asynchronous Receiver/Transmitter) is a simple serial communication protocol mainly designed for short-distance, point-to-point communication with minimal hardware complexity. CAN (Controller Area Network) supports multi-node, robust communication with error detection and fault confinement, making it highly suitable for automotive and industrial environments. UART operates with asynchronous data transmission, while CAN uses a multi-master protocol capable of prioritizing messages and ensuring data integrity through cyclic redundancy checks (CRC).

Communication Topologies: UART vs CAN

UART operates primarily in a point-to-point communication topology, enabling direct, simple connections between two devices with minimal wiring complexity. CAN utilizes a multi-master, multi-drop bus topology, allowing multiple nodes to communicate over a single shared medium, enhancing network scalability and fault tolerance. This differentiation in communication topologies makes UART suitable for simple, short-distance data exchanges, while CAN excels in complex automotive and industrial networks requiring robust message arbitration and error handling.

Data Transmission Speeds: UART vs CAN

UART typically supports data transmission speeds ranging from 115.2 kbps to 1 Mbps, depending on the hardware and configuration, making it suitable for low to moderate speed serial communication. CAN bus offers higher speeds up to 1 Mbps in classical CAN and up to 5 Mbps in CAN FD, providing robust real-time communication for automotive and industrial applications. The superior speed and error-handling capabilities of CAN make it ideal for complex networks requiring reliable, high-speed data exchange compared to UART's simpler, point-to-point communication.

Error Handling Mechanisms

UART error handling relies primarily on parity bits, framing errors, and overrun detection to identify and signal data corruption, making it suitable for simple point-to-point communication. In contrast, CAN implements a robust error handling mechanism with cyclic redundancy check (CRC), error detection counters, and automatic retransmission to ensure reliable data integrity in noisy automotive and industrial environments. CAN's sophisticated error confinement and fault tolerance surpass UART's basic error detection capabilities, enhancing system stability in complex networked hardware.

Hardware Requirements and Complexity

UART hardware requires minimal components, typically only a transmitter, receiver, and a common ground, making it simpler and more cost-effective for point-to-point communication. CAN hardware incorporates a specialized controller and transceiver to support multi-node networks with robust error detection and fault confinement, resulting in higher complexity and increased hardware cost. The need for differential signaling and termination resistors in CAN adds to the overall hardware complexity compared to UART's single-ended signaling.

Scalability and Network Size Comparison

UART supports point-to-point communication with limited scalability and is ideal for simple, short-distance connections between two devices. CAN (Controller Area Network) enables multi-node networks with up to 1,024 devices on a single bus, offering superior scalability for automotive and industrial applications. CAN's robust arbitration and error-handling mechanisms make it suitable for complex, large-scale networks, unlike UART's straightforward serial interface.

Use Cases and Industry Applications

UART is commonly used in low-speed serial communication applications such as microcontroller programming, sensor data transfer, and debug interfaces due to its simplicity and cost-effectiveness. CAN (Controller Area Network) excels in automotive, industrial automation, and heavy machinery environments where robust, multi-node communication with error detection and real-time capabilities is essential. Industries like automotive manufacturing, robotics, and aerospace rely on CAN for its fault tolerance and scalability, while UART suits embedded systems and consumer electronics requiring straightforward point-to-point data exchange.

Cost Implications of UART and CAN

UART communication modules typically have lower hardware costs due to simpler wiring and fewer required components, making them ideal for basic and short-distance serial communication tasks. CAN bus systems involve higher initial investment owing to their robust error detection, multi-node support, and longer distance capabilities, which require more complex transceivers and controllers. Cost implications also extend to scalability and maintenance, where CAN offers long-term savings in industrial environments despite higher upfront expenses.

Choosing the Right Protocol for Your Product

Choosing the right communication protocol for your product depends on specific hardware requirements such as data rate, distance, and network complexity. UART provides a simple, cost-effective solution for point-to-point communication with limited data speed and range, ideal for basic serial interfaces. CAN offers robust error handling, multi-node networking, and higher reliability in noisy environments, making it suitable for automotive and industrial applications requiring real-time data exchange.

UART vs CAN Infographic

productdif.com

productdif.com