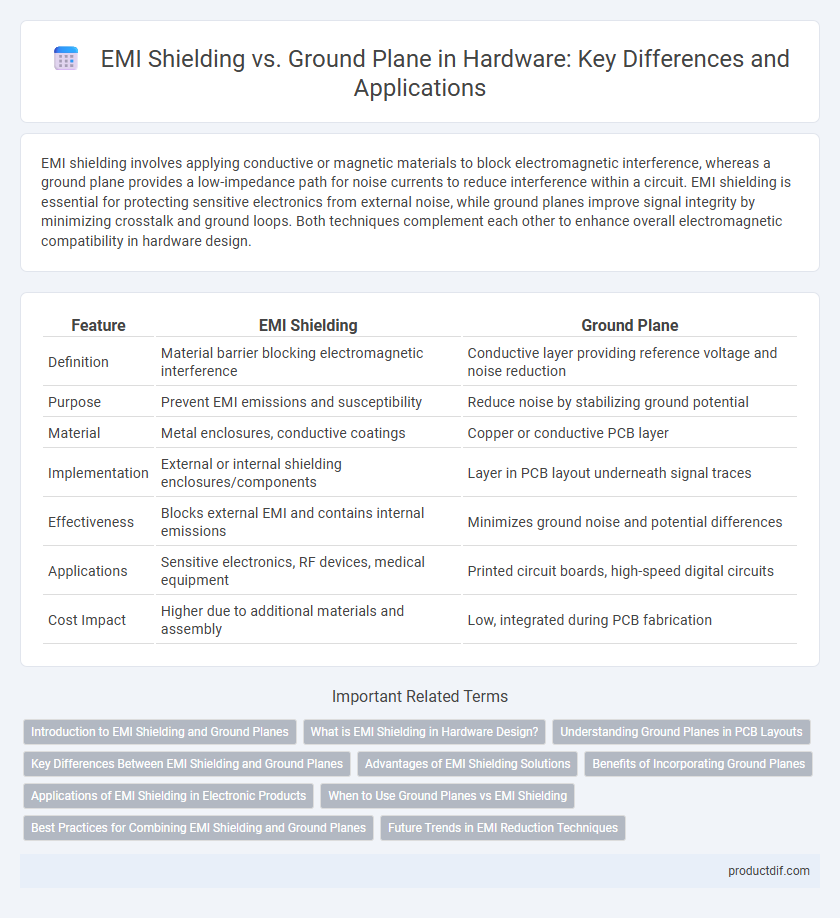

EMI shielding involves applying conductive or magnetic materials to block electromagnetic interference, whereas a ground plane provides a low-impedance path for noise currents to reduce interference within a circuit. EMI shielding is essential for protecting sensitive electronics from external noise, while ground planes improve signal integrity by minimizing crosstalk and ground loops. Both techniques complement each other to enhance overall electromagnetic compatibility in hardware design.

Table of Comparison

| Feature | EMI Shielding | Ground Plane |

|---|---|---|

| Definition | Material barrier blocking electromagnetic interference | Conductive layer providing reference voltage and noise reduction |

| Purpose | Prevent EMI emissions and susceptibility | Reduce noise by stabilizing ground potential |

| Material | Metal enclosures, conductive coatings | Copper or conductive PCB layer |

| Implementation | External or internal shielding enclosures/components | Layer in PCB layout underneath signal traces |

| Effectiveness | Blocks external EMI and contains internal emissions | Minimizes ground noise and potential differences |

| Applications | Sensitive electronics, RF devices, medical equipment | Printed circuit boards, high-speed digital circuits |

| Cost Impact | Higher due to additional materials and assembly | Low, integrated during PCB fabrication |

Introduction to EMI Shielding and Ground Planes

EMI shielding involves using conductive or magnetic materials to block electromagnetic interference and protect sensitive electronic components from signal disruption. Ground planes serve as a low-impedance reference point in circuits, minimizing noise and providing a return path for electrical currents to reduce interference. Both techniques are critical in hardware design for enhancing electromagnetic compatibility and ensuring signal integrity.

What is EMI Shielding in Hardware Design?

EMI shielding in hardware design refers to the use of conductive or magnetic materials to block or reduce electromagnetic interference that can disrupt electronic circuits. It typically involves enclosing sensitive components or entire devices within metal cases or applying coatings to prevent unwanted noise from external sources or internal emissions. Effective EMI shielding ensures device reliability, signal integrity, and compliance with regulatory standards.

Understanding Ground Planes in PCB Layouts

Ground planes in PCB layouts provide a low-impedance return path for signals, minimizing electromagnetic interference (EMI) by stabilizing voltage levels and reducing noise. Unlike EMI shielding, which uses conductive enclosures or materials to block interference externally, ground planes inherently control signal integrity within the board's structure. Effective use of ground planes improves overall circuit performance by enhancing isolation and reducing radiated emissions.

Key Differences Between EMI Shielding and Ground Planes

EMI shielding uses conductive or magnetic materials to block or attenuate electromagnetic interference by creating a barrier around sensitive components, while ground planes serve as reference points in circuit design to reduce noise and provide a common return path for current. EMI shielding physically isolates signals from external electromagnetic fields, whereas ground planes manage signal integrity by minimizing voltage fluctuations and electromagnetic emissions within the PCB layout. The key difference lies in EMI shielding's role as a protective enclosure versus ground planes' function in circuit stability and noise reduction.

Advantages of EMI Shielding Solutions

EMI shielding solutions provide targeted protection by effectively blocking electromagnetic interference, reducing signal degradation in sensitive electronics. These solutions offer flexibility in design, allowing customization for specific frequency ranges and environmental conditions, unlike ground planes that primarily serve as a reference point for signal return paths. Implementing EMI shields enhances device reliability and compliance with regulatory standards by minimizing electromagnetic emissions and susceptibility.

Benefits of Incorporating Ground Planes

Incorporating ground planes in hardware design enhances EMI shielding by providing a low-impedance path that reduces electromagnetic interference and signal noise. Ground planes improve signal integrity and minimize crosstalk between traces, leading to more stable and reliable circuit performance. This approach also simplifies PCB layout by offering consistent reference voltage and effective heat dissipation.

Applications of EMI Shielding in Electronic Products

EMI shielding is crucial in electronic products such as smartphones, medical devices, and automotive systems to prevent electromagnetic interference that can disrupt functionality and data integrity. Unlike ground planes that primarily reduce noise through grounding, EMI shielding employs conductive materials to block or attenuate electromagnetic waves, enhancing device reliability in high-frequency environments. Applications include protecting sensitive circuits, ensuring compliance with regulatory standards, and improving overall electromagnetic compatibility (EMC) in complex electronic assemblies.

When to Use Ground Planes vs EMI Shielding

Ground planes are ideal for minimizing electromagnetic interference in multilayer PCB designs by providing a continuous reference surface to control signal integrity and reduce noise coupling. EMI shielding is more effective for preventing external interference or containing emissions from high-frequency or high-power components, especially in sensitive analog or RF circuits. Use ground planes primarily for internal circuit noise reduction, while EMI shielding is necessary when exposure to harsh electromagnetic environments or regulatory compliance is required.

Best Practices for Combining EMI Shielding and Ground Planes

Effective EMI shielding and ground plane design require careful integration to minimize electromagnetic interference in hardware systems. Implementing continuous ground planes beneath shielding materials enhances signal integrity by providing a low-impedance return path and reducing ground loops. Using proper bonding techniques and maintaining shield continuity while ensuring optimal vias placement around ground planes further improves overall EMI suppression performance.

Future Trends in EMI Reduction Techniques

Future trends in EMI reduction techniques emphasize advanced materials for EMI shielding, such as nanocomposites and conductive polymers, which offer lightweight and flexible protection without sacrificing performance. Ground plane design is evolving with adaptive layouts and integrated filtering components to minimize electromagnetic interference at the PCB level. Emerging technologies combine active EMI cancellation with traditional shielding and ground planes to achieve superior noise suppression in high-frequency, densely packed electronic systems.

EMI Shielding vs Ground Plane Infographic

productdif.com

productdif.com