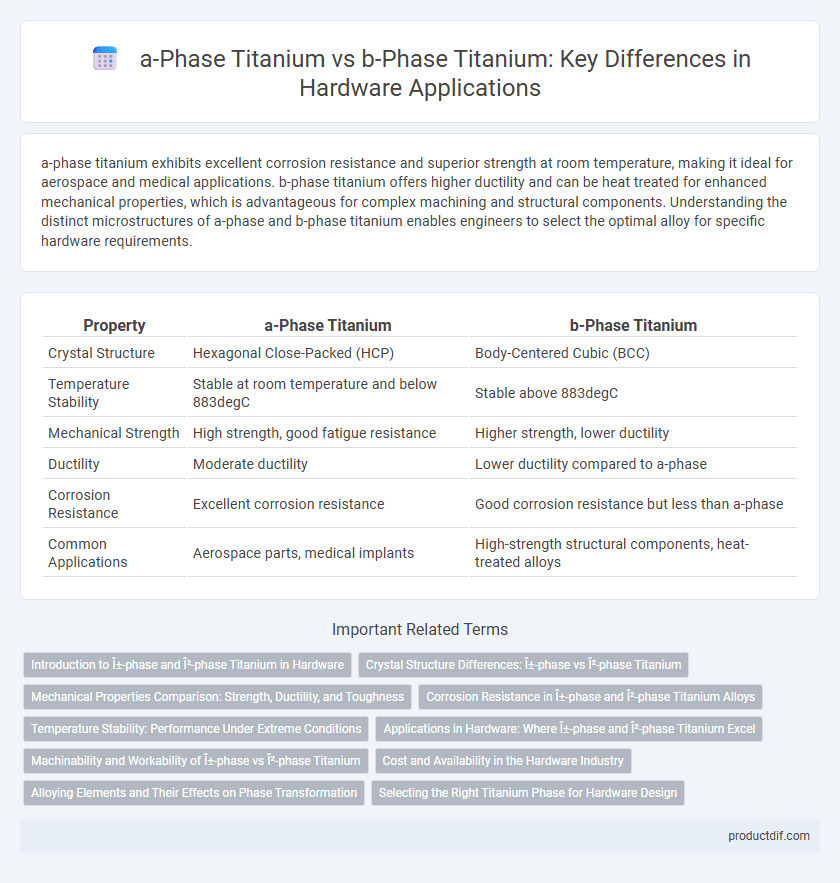

a-phase titanium exhibits excellent corrosion resistance and superior strength at room temperature, making it ideal for aerospace and medical applications. b-phase titanium offers higher ductility and can be heat treated for enhanced mechanical properties, which is advantageous for complex machining and structural components. Understanding the distinct microstructures of a-phase and b-phase titanium enables engineers to select the optimal alloy for specific hardware requirements.

Table of Comparison

| Property | a-Phase Titanium | b-Phase Titanium |

|---|---|---|

| Crystal Structure | Hexagonal Close-Packed (HCP) | Body-Centered Cubic (BCC) |

| Temperature Stability | Stable at room temperature and below 883degC | Stable above 883degC |

| Mechanical Strength | High strength, good fatigue resistance | Higher strength, lower ductility |

| Ductility | Moderate ductility | Lower ductility compared to a-phase |

| Corrosion Resistance | Excellent corrosion resistance | Good corrosion resistance but less than a-phase |

| Common Applications | Aerospace parts, medical implants | High-strength structural components, heat-treated alloys |

Introduction to α-phase and β-phase Titanium in Hardware

a-phase titanium exhibits a hexagonal close-packed crystal structure, providing high strength, excellent corrosion resistance, and superior performance at elevated temperatures, making it ideal for aerospace hardware and structural components. b-phase titanium has a body-centered cubic crystal structure, allowing for enhanced ductility, greater formability, and lower density, which benefits the manufacturing of lightweight, high-strength hardware parts. The ability to alloy and heat-treat b-phase titanium enables tailored mechanical properties for specialized hardware applications requiring both toughness and flexibility.

Crystal Structure Differences: α-phase vs β-phase Titanium

a-phase Titanium exhibits a hexagonal close-packed (HCP) crystal structure, resulting in excellent strength and corrosion resistance at room temperature. In contrast, b-phase Titanium has a body-centered cubic (BCC) crystal structure, offering higher ductility and improved formability at elevated temperatures. The distinct atomic arrangements in a-phase and b-phase Titanium directly influence mechanical properties and processing behaviors in hardware applications.

Mechanical Properties Comparison: Strength, Ductility, and Toughness

a-phase titanium exhibits higher strength and better fatigue resistance due to its hexagonal close-packed structure, making it ideal for aerospace applications requiring rigidity. b-phase titanium, with a body-centered cubic structure, offers superior ductility and toughness, allowing extensive deformation without fracture, favored in automotive and biomedical fields. The mechanical properties of a-phase titanium prioritize tensile strength and creep resistance, whereas b-phase titanium emphasizes impact resistance and formability.

Corrosion Resistance in α-phase and β-phase Titanium Alloys

a-phase titanium alloys exhibit superior corrosion resistance due to their hexagonal close-packed (HCP) crystal structure, which forms a stable and protective oxide layer, effectively resisting oxidation and chemical degradation. In contrast, b-phase titanium alloys, characterized by a body-centered cubic (BCC) structure, demonstrate comparatively lower corrosion resistance because their microstructure is more susceptible to localized attack and hydrogen embrittlement. The enhanced corrosion resistance of a-phase titanium makes it ideal for aerospace and marine applications where durability against aggressive environments is critical.

Temperature Stability: Performance Under Extreme Conditions

a-phase Titanium exhibits superior temperature stability with excellent performance in high-temperature environments up to approximately 500degC, maintaining strength and corrosion resistance. b-phase Titanium, while less stable at elevated temperatures, offers increased ductility and toughness, performing well under rapid temperature changes and extreme mechanical stress conditions. The choice between a-phase and b-phase Titanium depends on specific hardware applications requiring either sustained high-temperature stability or enhanced mechanical flexibility.

Applications in Hardware: Where α-phase and β-phase Titanium Excel

a-phase Titanium exhibits exceptional strength and corrosion resistance, making it ideal for aerospace hardware components such as airframes and engine parts. b-phase Titanium offers superior formability and heat treatment capabilities, which is advantageous for manufacturing hardware like fasteners, springs, and structural supports requiring complex shapes. Both phases are critical in hardware applications where specific mechanical properties and environmental durability are essential.

Machinability and Workability of α-phase vs β-phase Titanium

a-phase titanium exhibits superior workability due to its hexagonal close-packed (HCP) crystal structure, which provides excellent formability and moderate machinability. In contrast, b-phase titanium, with its body-centered cubic (BCC) structure, offers enhanced machinability but reduced workability compared to a-phase because it is harder and stronger. The combination of a and b phases in titanium alloys allows for tailored machinability and workability properties suitable for various hardware applications.

Cost and Availability in the Hardware Industry

a-phase titanium, known for its excellent corrosion resistance and strength, generally commands higher prices due to complex processing methods and limited supply, impacting hardware industry budgets. b-phase titanium offers greater availability and lower production costs because of easier alloying and faster manufacturing cycles, making it a cost-effective alternative for structural hardware applications. Manufacturers prioritize b-phase titanium when balancing performance requirements with cost constraints and material accessibility.

Alloying Elements and Their Effects on Phase Transformation

a-phase titanium primarily contains aluminum and oxygen as alloying elements, which stabilize the hexagonal close-packed (HCP) crystal structure and enhance strength at elevated temperatures. b-phase titanium is stabilized by elements such as vanadium, molybdenum, and niobium, which promote the body-centered cubic (BCC) structure and improve toughness and ductility. The specific combination and concentration of these alloying elements control the phase transformation temperatures, directly influencing mechanical properties and suitability for aerospace and biomedical applications.

Selecting the Right Titanium Phase for Hardware Design

Selecting between a-phase and b-phase titanium for hardware design hinges on the specific mechanical and thermal properties required. a-phase titanium offers superior corrosion resistance and high strength at elevated temperatures, making it ideal for aerospace and chemical processing equipment. b-phase titanium provides greater ductility and ease of machining, suited for complex shapes and components requiring extensive forming or welding.

α-phase Titanium vs β-phase Titanium Infographic

productdif.com

productdif.com