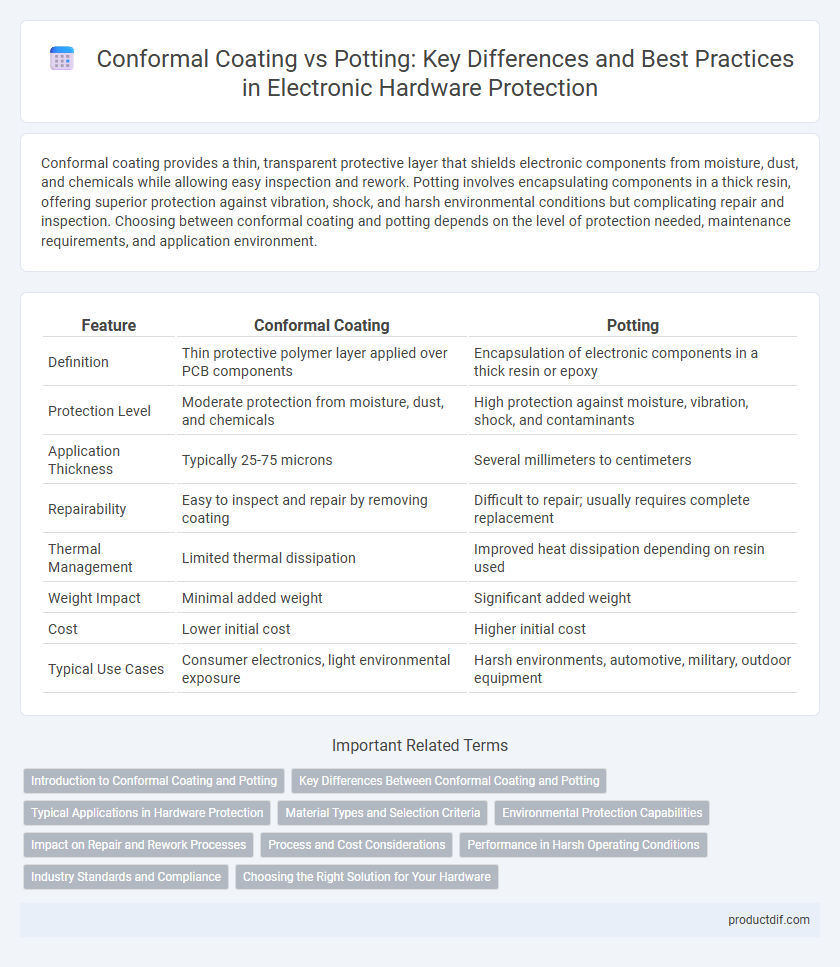

Conformal coating provides a thin, transparent protective layer that shields electronic components from moisture, dust, and chemicals while allowing easy inspection and rework. Potting involves encapsulating components in a thick resin, offering superior protection against vibration, shock, and harsh environmental conditions but complicating repair and inspection. Choosing between conformal coating and potting depends on the level of protection needed, maintenance requirements, and application environment.

Table of Comparison

| Feature | Conformal Coating | Potting |

|---|---|---|

| Definition | Thin protective polymer layer applied over PCB components | Encapsulation of electronic components in a thick resin or epoxy |

| Protection Level | Moderate protection from moisture, dust, and chemicals | High protection against moisture, vibration, shock, and contaminants |

| Application Thickness | Typically 25-75 microns | Several millimeters to centimeters |

| Repairability | Easy to inspect and repair by removing coating | Difficult to repair; usually requires complete replacement |

| Thermal Management | Limited thermal dissipation | Improved heat dissipation depending on resin used |

| Weight Impact | Minimal added weight | Significant added weight |

| Cost | Lower initial cost | Higher initial cost |

| Typical Use Cases | Consumer electronics, light environmental exposure | Harsh environments, automotive, military, outdoor equipment |

Introduction to Conformal Coating and Potting

Conformal coating is a thin, protective layer applied to electronic circuit boards to safeguard against moisture, dust, and chemical contaminants while maintaining flexibility and allowing heat dissipation. Potting involves encasing electronic components in a solid or gel-like resin to provide robust mechanical protection, thermal management, and enhanced resistance to vibrations and environmental hazards. Both methods are essential in hardware protection, with conformal coating preferred for lightweight applications and potting favored for heavy-duty insulation and durability.

Key Differences Between Conformal Coating and Potting

Conformal coating is a thin, protective polymer layer applied directly to circuit boards to shield against moisture, dust, and chemicals while maintaining flexibility and ease of inspection. Potting involves encapsulating electronic assemblies in a solid or gel-like compound, providing robust mechanical protection and enhanced resistance to environmental stressors but making repairs more difficult. The primary differences lie in the thickness, protection level, application complexity, and repairability, where conformal coatings offer lightweight protection and easy inspection, and potting ensures heavy-duty encapsulation for severe conditions.

Typical Applications in Hardware Protection

Conformal coating is typically applied in electronics where lightweight, thin protection is required for printed circuit boards (PCBs) against moisture, dust, and chemicals, commonly found in consumer electronics, automotive sensors, and medical devices. Potting is preferred in harsh environments demanding robust mechanical protection and high resistance to vibration, thermal cycling, and shock, frequently used in power modules, connectors, and industrial equipment. Selecting conformal coating or potting depends on the hardware's exposure level and required durability in operational conditions.

Material Types and Selection Criteria

Conformal coating materials typically include acrylics, silicones, urethanes, and epoxy resins, chosen for their thin, protective layers that conform to the contour of electronic components without adding bulk. Potting compounds often use epoxy, polyurethane, or silicone gels that encapsulate entire assemblies, providing superior mechanical support and environmental protection. Selection criteria hinge on factors such as environmental exposure, thermal management, electrical insulation requirements, and repairability, guiding the choice between flexible coatings and rigid potting materials.

Environmental Protection Capabilities

Conformal coating provides a thin, protective layer that shields electronic components from moisture, dust, and chemical contaminants while maintaining flexibility for thermal cycling. Potting involves encasing the entire assembly in a solid or gel-like material, offering superior protection against shock, vibration, and harsh environmental conditions. Both methods enhance device reliability, but potting generally delivers higher resistance to mechanical stresses and extreme environmental exposure.

Impact on Repair and Rework Processes

Conformal coating allows easier access for repair and rework as it provides a thin, protective layer that can be selectively removed without damaging components. Potting encapsulates the entire assembly in a solid compound, significantly complicating disassembly and often requiring complete replacement of the potted section. Repair and rework efficiency is higher with conformal coating due to its non-destructive nature, whereas potting offers superior protection at the cost of increased repair complexity and time.

Process and Cost Considerations

Conformal coating involves applying a thin protective polymer layer onto electronic assemblies to shield against moisture, dust, and chemicals, typically using spray or dip methods, which keeps costs lower due to minimal material use and simpler rework. Potting encapsulates components entirely in resin, offering superior protection against environmental stress and mechanical shock but requires longer curing times and increases material expenses substantially. The choice hinges on balancing process complexity, production volume, and overall budget constraints, with conformal coating favored for cost-effective, repairable solutions and potting preferred for extreme durability requirements.

Performance in Harsh Operating Conditions

Conformal coating offers excellent protection against moisture, dust, and chemical exposure while maintaining component accessibility for inspection and repair in harsh operating conditions. Potting provides superior mechanical strength and environmental sealing by encapsulating the entire assembly, ensuring enhanced resistance to vibration, shock, and extreme temperatures. Selecting between conformal coating and potting depends on the balance between protection level and serviceability required for specific hardware applications.

Industry Standards and Compliance

Conformal coating and potting are essential processes in hardware protection, with industry standards such as IPC-CC-830 governing conformal coatings and IPC-4566 guiding potting materials, ensuring reliable insulation and environmental resistance. Compliance with these standards guarantees performance under specific conditions like moisture, vibration, and temperature extremes, critical for aerospace, automotive, and defense applications. Manufacturers must select coatings or potting compounds certified to meet IEC, UL, and MIL-STD requirements to achieve optimal durability and regulatory acceptance.

Choosing the Right Solution for Your Hardware

Selecting the optimal protective method for hardware depends on the specific environmental and operational demands of the device. Conformal coating offers a thin, flexible layer ideal for protecting delicate electronics against moisture, dust, and chemicals while maintaining ease of inspection and rework. Potting provides a thicker, robust encapsulation suited for extreme conditions requiring enhanced mechanical strength, thermal dissipation, and vibration resistance.

Conformal Coating vs Potting Infographic

productdif.com

productdif.com